An automatic oiling device for the top roller of a draw frame

An automatic refueling and refueling device technology, which is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of frequent refueling, etc., and achieve the effect of high degree of automation, constant oil volume and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

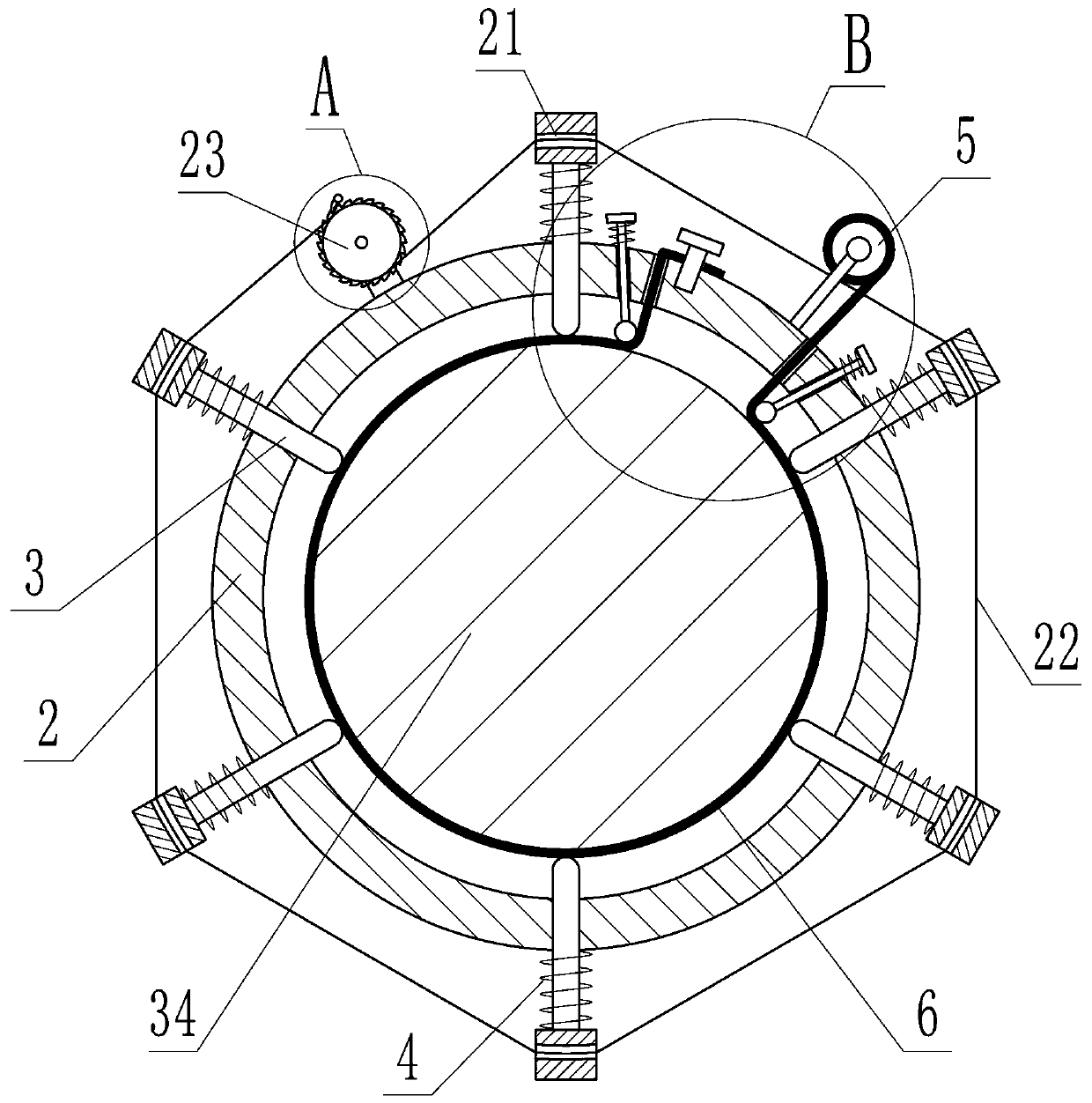

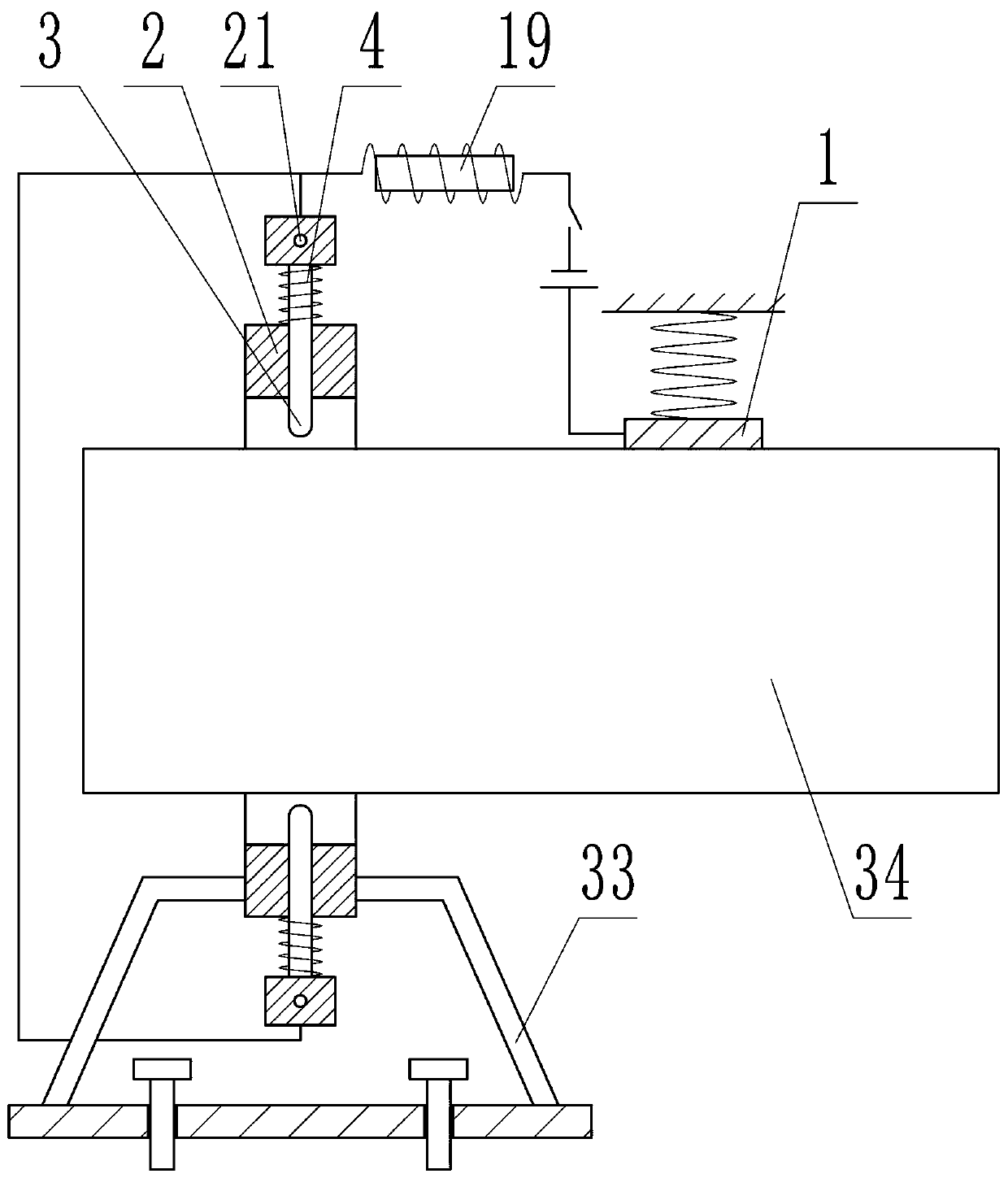

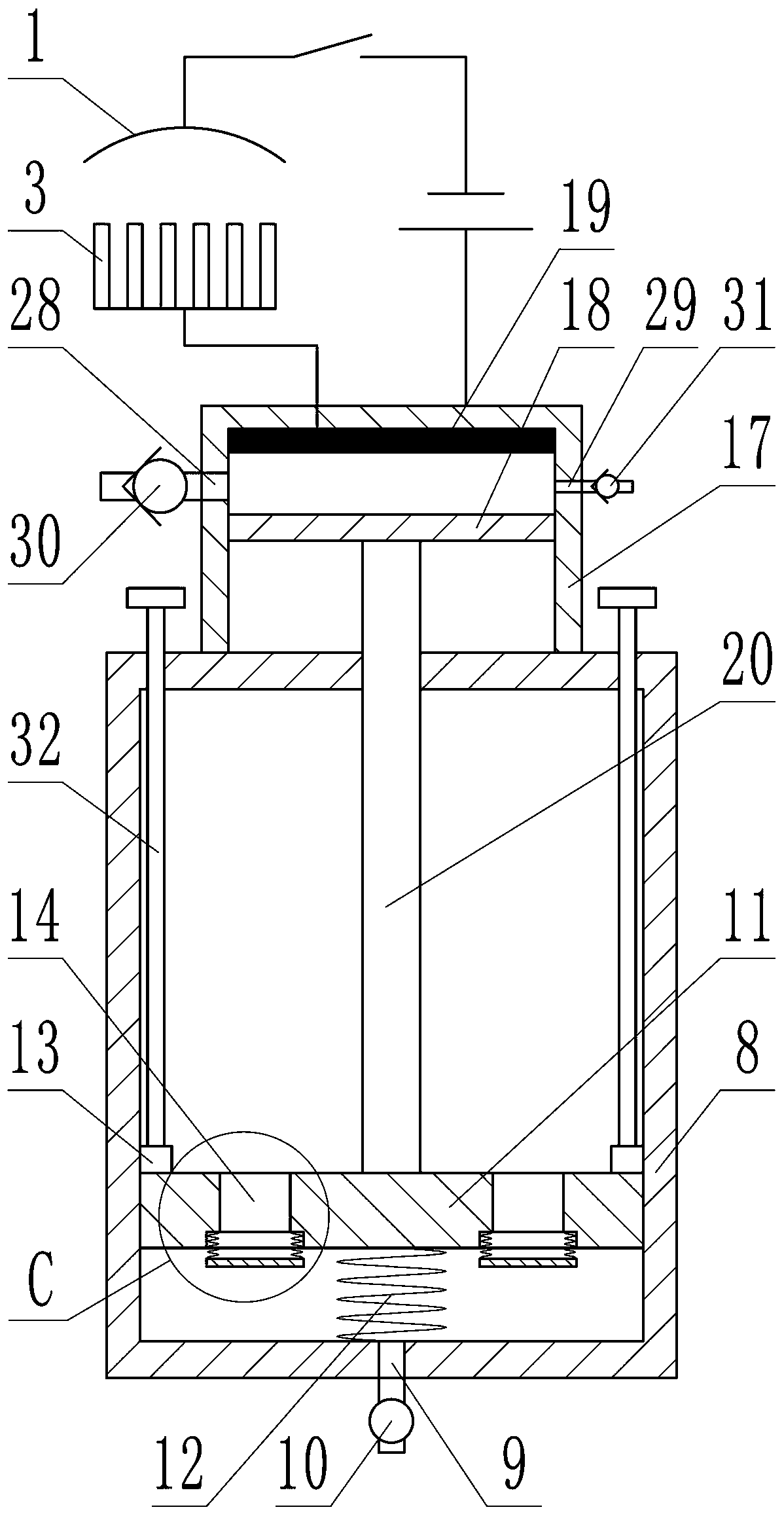

[0018] Depend on Figure 1 to Figure 6 Given, the present invention includes detection device and refueling device, and detection device comprises a brush 1 and an annular sleeve 2, and annular sleeve 2 is coaxially sleeved on the mandrel of top roller, and the circumference of the side wall of annular sleeve 2 is evenly distributed A plurality of conductive guide rods 3 passing through its side wall in the radial direction, the plurality of guide rods 3 can move radially along the annular sleeve 2 in the same direction at the same time, and the outer end of each guide rod 3 is connected to the outer wall of the annular sleeve 2 There is a first compression spring 4; a ring of steel belt 6 is arranged in the annular sleeve, and the steel belt 6 can be wrapped around the mandrel and can be closely attached to the mandrel;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com