Compressor refrigerant oil backflow device and air conditioner

A reflux device and refrigeration oil technology, which is applied in the field of compressors, can solve the problems of poor oil separator effect, difficult recovery, oil level protection shutdown, etc., and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

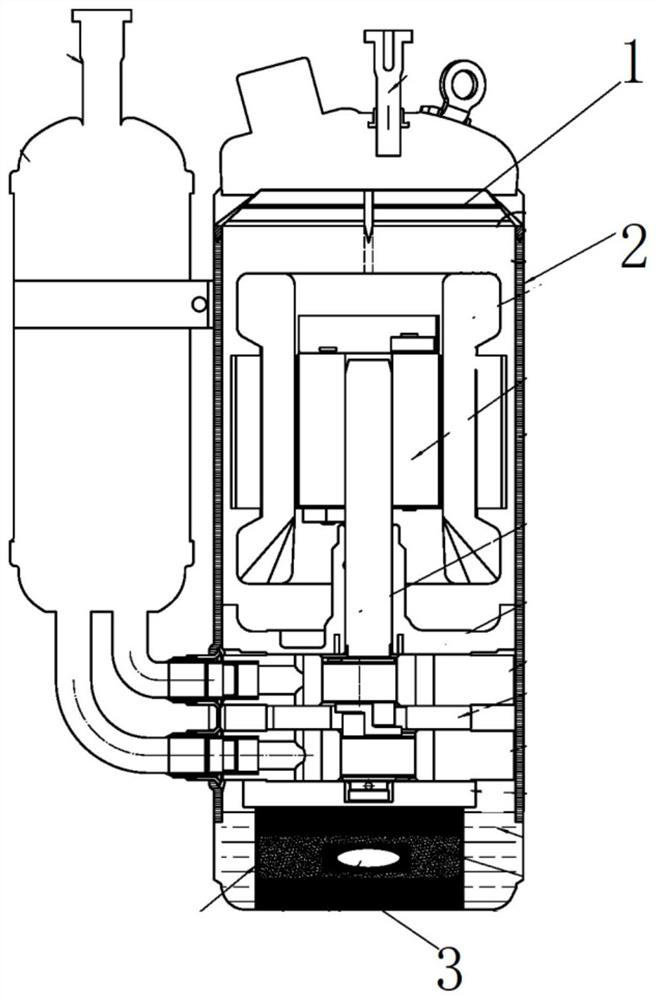

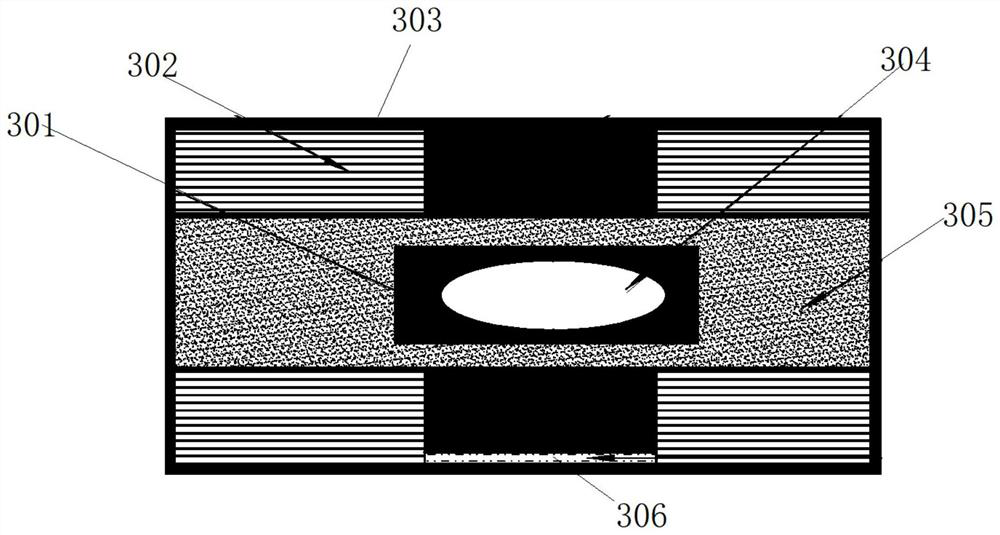

[0027] Such as figure 1 As shown, a compressor refrigerating oil return device includes a casing, the casing is provided with a stator and a pump body, the bottom of the casing is provided with refrigerating oil, and the inside of the casing is provided with a suction plate 1 and a magnetic Seat 3, the suction plate 1 is located above the stator, the magnetic base 3 is located in the refrigerated oil and connected to the bottom of the casing, the upper end of the magnetic base 3 is connected to the pump body, and the magnetic base 3 is electrically connected to the suction plate 1 Connection, the inside of the casing is vertically provided with an oil return pipe 2, the oil return pipe 2 is made of antimagnetic material, the upper end of the oil return pipe 2 is connected with the suction plate 1, and the lower end of the oil return pipe 2 is located in the refrigerated oil.

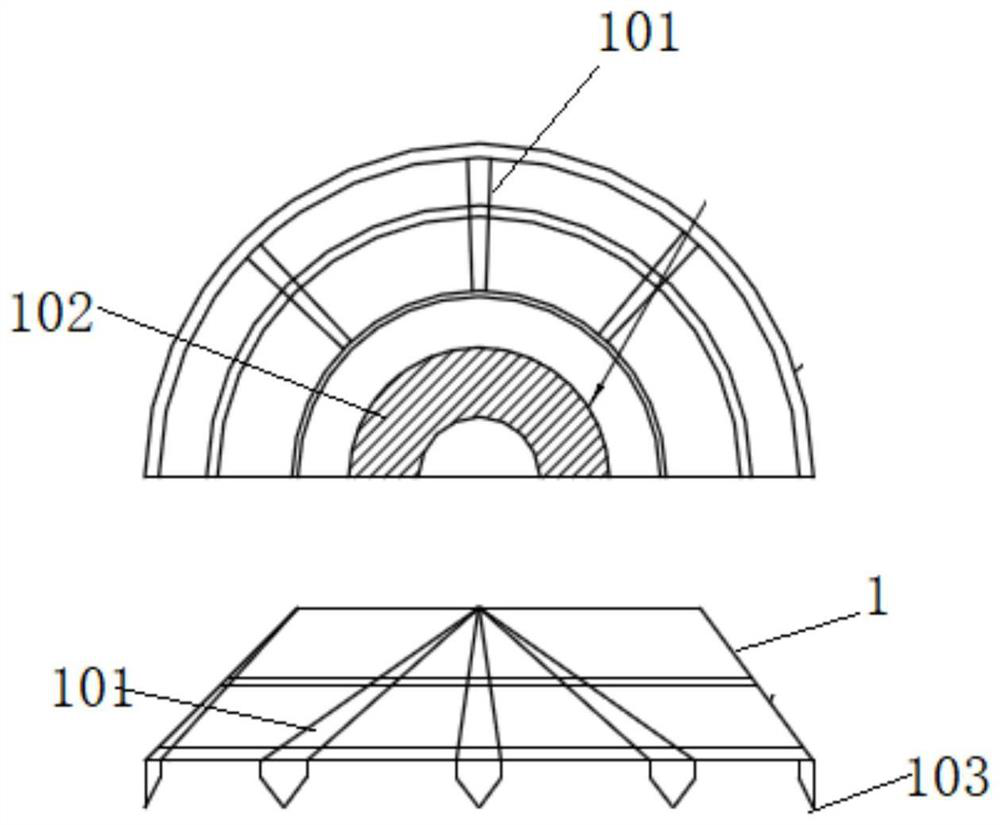

[0028] Such as figure 2 As shown, the suction plate 1 is a cylindrical structure, and the diameter ...

Embodiment 2

[0036] Such as figure 1 As shown, a compressor refrigerating oil return device includes a casing, the casing is provided with a stator and a pump body, the bottom of the casing is provided with refrigerating oil, and the inside of the casing is provided with a suction plate 1 and a magnetic Seat 3, the suction plate 1 is located above the stator, the magnetic base 3 is located in the refrigerated oil and connected to the bottom of the casing, the upper end of the magnetic base 3 is connected to the pump body, and the magnetic base 3 is electrically connected to the suction plate 1 Connection, the inside of the casing is vertically provided with an oil return pipe 2, the oil return pipe 2 is made of antimagnetic material, the upper end of the oil return pipe 2 is connected with the suction plate 1, and the lower end of the oil return pipe 2 is located in the refrigerated oil.

[0037] Such as figure 2 As shown, the suction plate 1 is a cylindrical structure, and the diameter ...

Embodiment 3

[0043]Such as Figure 1-4 As shown, an air conditioner includes a compressor refrigeration oil return device, including a casing, a stator and a pump body are arranged inside the casing, refrigeration oil is arranged at the bottom of the casing, and a suction plate is arranged inside the casing 1 and magnetic base 3, the suction plate 1 is located above the stator, the magnetic base 3 is located in the refrigeration oil and connected to the bottom of the casing, the upper end of the magnetic base 3 is connected to the pump body, and the magnetic base 3 is connected to the suction The plate 1 is electrically connected, and the inside of the casing is vertically provided with an oil return pipe 2, which is made of antimagnetic material. The upper end of the oil return pipe 2 is connected with the suction plate 1, and the lower end of the oil return pipe 2 is located in the refrigeration oil.

[0044] The suction plate 1 is a cylindrical structure, and the diameter of the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com