Abutting-locking type butterfly valve

A locking, butterfly valve technology, used in lift valves, valve devices, engine components, etc., can solve problems such as increased costs for enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

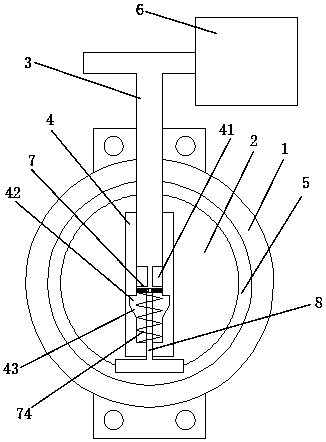

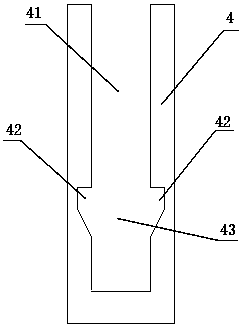

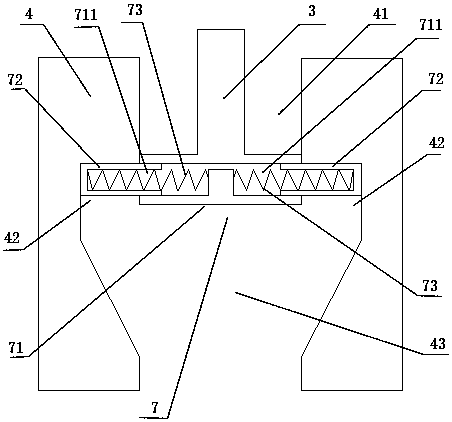

[0022] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to 7 As shown, a pressure locking butterfly valve includes a valve body 1, a valve plate 2, a connecting sleeve 4, a driving rod 3, a telescopic assembly 7, and a pressure screw 8. The valve body 2 has an annular structure; the valve plate 2 is installed inside the valve body 1; the connecting sleeve 4 is fixedly installed on one side of the valve plate 2; the upper end of the connecting sleeve 4 is open, The connecting sleeve 4 is provided with an insertion cavity 41; the lower two sides of the insertion cavity 41 each extend to the outside with a clamping groove 42; the lower end of the clamping groove 42 is provided with a tapered sliding groove 43; The tapered slide groove 43 has a tapered structure with a large upper and a small lower end; the lower end of the driving rod 3 is equipped with a telescopic assembly 7; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com