secondary battery

A secondary battery and electrode technology, applied in secondary battery manufacturing, battery pack parts, electrolyte storage battery manufacturing, etc., can solve the problems of narrowing of the tab portion, adverse effects of subsequent processes, and large sagging of the tab portion, etc. The effect of suppressing sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

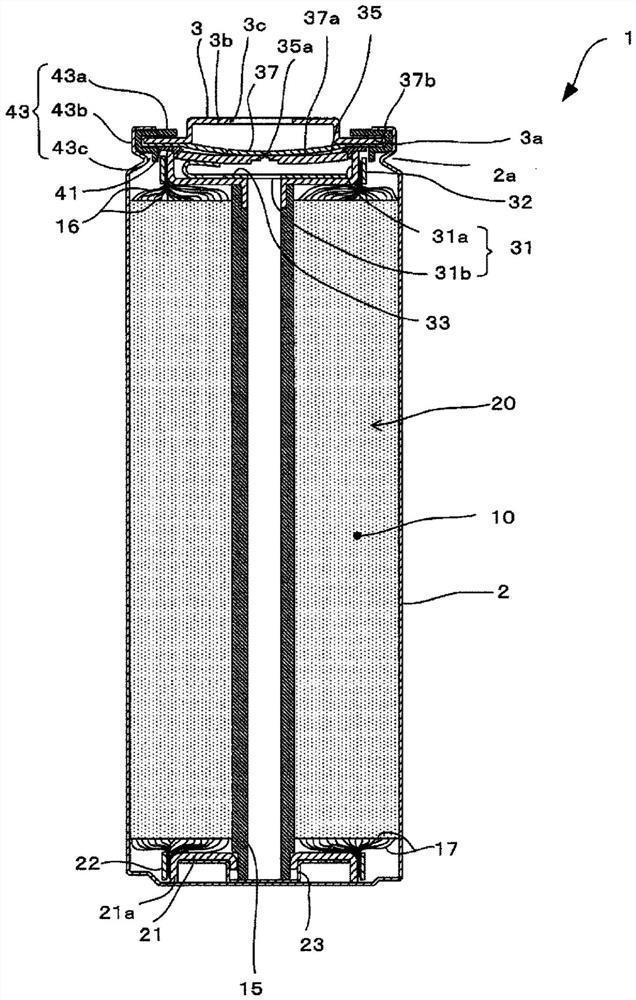

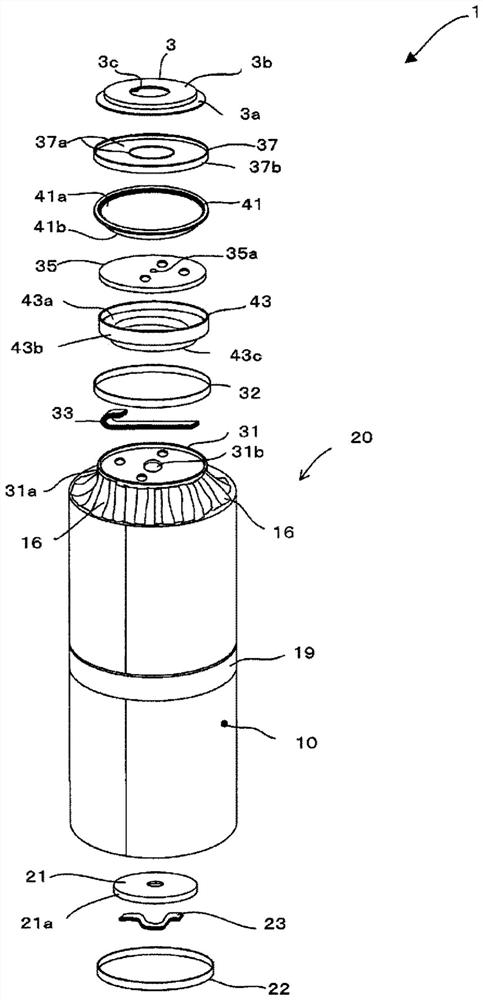

[0035] Hereinafter, regarding the secondary battery of the present invention, as a first embodiment, an attached Figure 1 The cylindrical lithium ion secondary battery will be described starting from the beginning.

[0036] [Structure of Cylindrical Li-ion Secondary Battery]

[0037] figure 1 To show a cross-sectional view of one embodiment of a cylindrical lithium ion secondary battery, figure 2 for figure 1 An exploded perspective view of the cylindrical lithium-ion secondary battery shown. The cylindrical lithium ion secondary battery 1 has, for example, an outer shape The size of height 92mm. In this cylindrical lithium ion secondary battery 1 , components for power generation described below are accommodated in a bottomed cylindrical battery can 2 and a hat-shaped upper cover 3 . In the bottomed cylindrical battery can 2, a groove 2a protruding inwardly of the battery can 2 is formed on the upper end side which is the open side.

[0038] (electrode set)

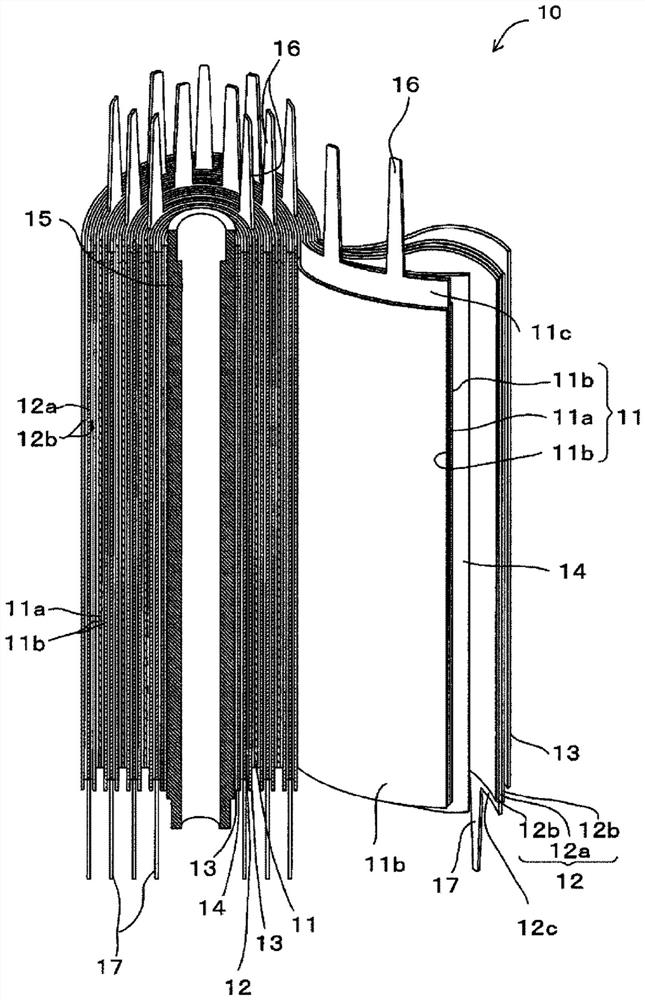

[0039...

no. 2 Embodiment approach >

[0091] Figure 12 (A) and (B) are diagrams showing the second embodiment of the deformation enhancing portion. Figure 12 (A) in (A) is the enlarged plan view near the tab, Figure 12 (B) in Figure 12 Side view of (A) in. Structure of Cylindrical Lithium Ion Secondary Battery, Manufacturing Method and Reference of Cylindrical Lithium Ion Secondary Battery Figure 1 to Figure 8 The same applies to the first embodiment described below.

[0092] Such as Figure 12 As shown in (A), for the negative electrode tab 17 and the negative electrode mixture layer uncoated region 12c integrally, one side edge 61 along the length direction of the negative electrode metal foil 12a is arranged at a predetermined interval.

[0093] Such as Figure 12 (A) in Figure 12 As shown in (B) in (B), the deformation enhancing portion is provided at the position of the uncoated region 12 c of the negative electrode mixture layer corresponding to the position of the negative electrode tab 17 . T...

no. 3 Embodiment approach >

[0096] Figure 13 (A) and (B) are diagrams showing the third embodiment of the deformation enhancing portion. Figure 13 (A) in (A) is the enlarged plan view near the tab, Figure 13 (B) in Figure 13 Side view of (A) in. Structure of Cylindrical Lithium Ion Secondary Battery, Manufacturing Method and Reference of Cylindrical Lithium Ion Secondary Battery Figure 1 to Figure 8 The same applies to the first embodiment described.

[0097] Such as Figure 13 As shown in (A), the negative electrode tabs 17 are integrally arranged at predetermined intervals along one side edge 61 of the negative electrode metal foil 12a in the longitudinal direction with the uncoated region 12c of the negative electrode mixture layer.

[0098] Such as Figure 13 (A) in Figure 13 As shown in (B), the deformation enhancing part is provided at the position of the negative electrode mixture layer uncoated region 12 c corresponding to the position of the negative electrode tab 17 and the central...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com