A kind of preparation method of flame-retardant superhydrophobic melamine sponge

A technology of water melamine sponge and melamine sponge, which is applied in the field of preparation of flame-retardant superhydrophobic melamine sponge, can solve problems such as poor flame retardancy, limited use of materials, and complicated construction process of superhydrophobic and lipophilic surfaces, and achieves easy preparation of raw materials The effect of obtaining and preparation conditions is simple and mild

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of flame-retardant superhydrophobic melamine sponge, the steps are as follows:

[0021] Step 1, the modified treatment of melamine sponge is the same as the preparation process of comparative example 1;

[0022] Step 2: Put the four melamine sponges modified in Comparative Example 1 into 30 mL ethanol solution, and add 30 μL of 1H, 1H, 2H, 2H-perfluorododecanethiol solution to the ethanol solution (i.e. The volume ratio of the melamine sponge to the ethanol solution containing 1H, 1H, 2H, 2H-perfluorododecanethiol is 2:15), stirred for 12 hours, took out the melamine sponge, washed 3 times with ethanol, dried, and finally obtained super Hydrophobic melamine sponge.

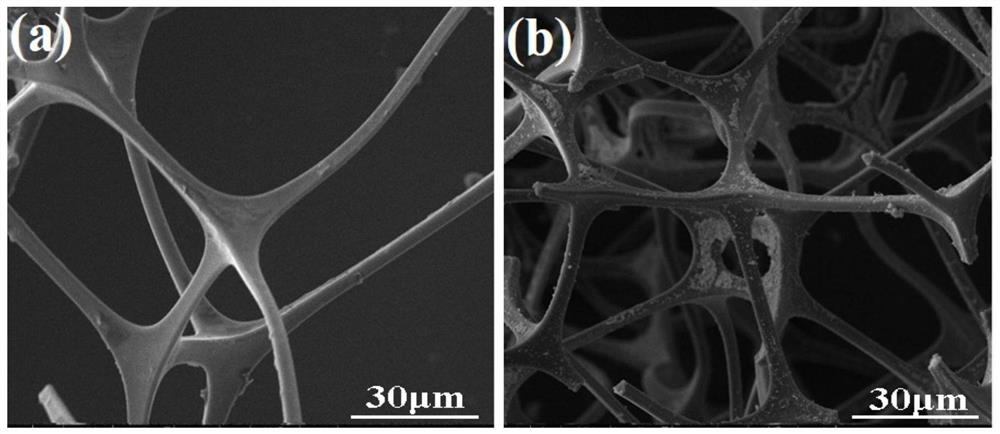

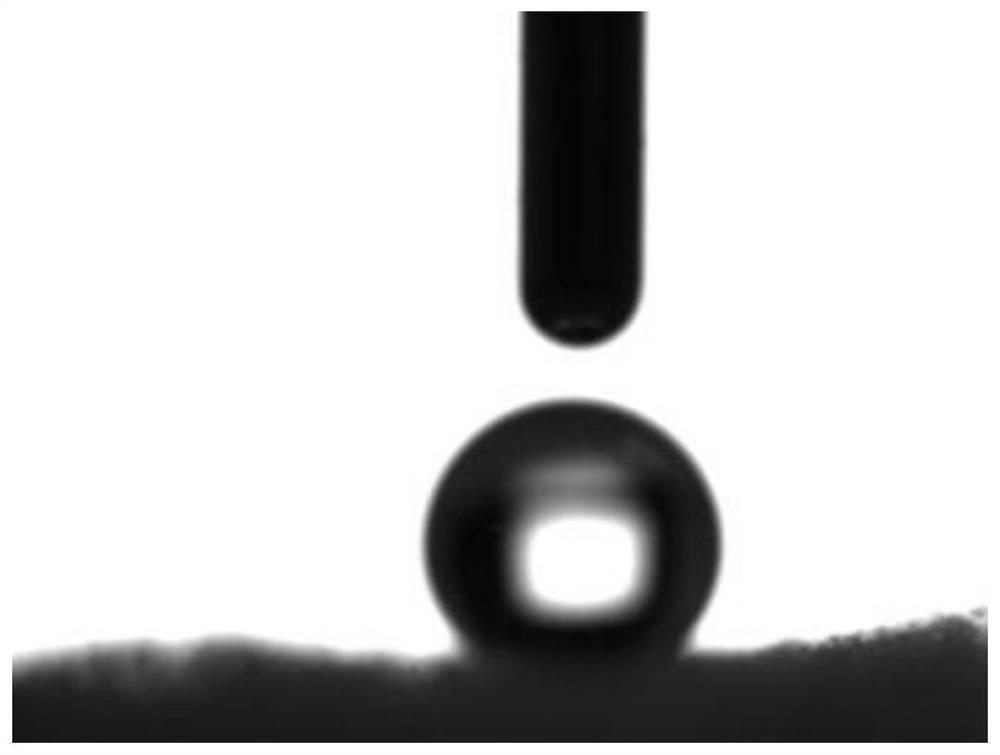

[0023] figure 2 Among (a) shows the SEM picture of the melamine sponge before modification, (b) shows the SEM picture of the superhydrophobic melamine sponge finally prepared by embodiment 1, image 3 It is the water contact angle (CA) photo of the superhydrophobic melamine...

Embodiment 2

[0024] Example 2: Preparation of flame-retardant superhydrophobic melamine sponge, the preparation steps of this example 2 are basically the same as those of Example 1, the difference is only: in step 2, the added 1H, 1H, 2H, 2H-perfluorodeca The dioxanethiol solution was changed from 30 μL to 60 μL. Figure 4 It is the water contact angle (CA) photo of the superhydrophobic melamine sponge prepared in embodiment 2. After modification with 1H,1H,2H,2H-perfluorododecanethiol, the surface energy of the melamine sponge was reduced. When the low surface energy substance concentration increased, that is, when the volume ratio of 1H, 1H, 2H, 2H-perfluorododecanethiol solution to ethanol solution was 1:500, compared with the water contact angle in Example 1, there was The water contact angle at this time is 160.74°.

Embodiment 3

[0025] Example 3: The preparation of flame-retardant superhydrophobic melamine sponge, the steps of this example 3 are basically the same as those of Example 1, the difference is only: in step 2, the 1H, 1H, 2H, 2H-perfluorododecane added Thiol solution was changed from 30 μL to 6 μL. Figure 5 It is the water contact angle (CA) photo of the superhydrophobic melamine sponge prepared in embodiment 3. When the concentration of low surface energy substances decreased, the water contact angle of the superhydrophobic melamine sponge also decreased. When the volume ratio of 1H, 1H, 2H, 2H-perfluorododecanethiol solution and ethanol solution was 1:5000, Compared with Example 2, the water contact angle decreased, and now the water contact angle was 152.22°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com