Preparation method of super-hydrophobic sponge for adsorbing organic solvent

A super-hydrophobic sponge and organic solvent technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of difficult re-use, high separation cost, low oil absorption, etc., and achieve simple and mild preparation conditions and the preparation of raw materials Inexpensive, the effect of regulating hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of superhydrophobic polyurethane sponge, the steps are as follows:

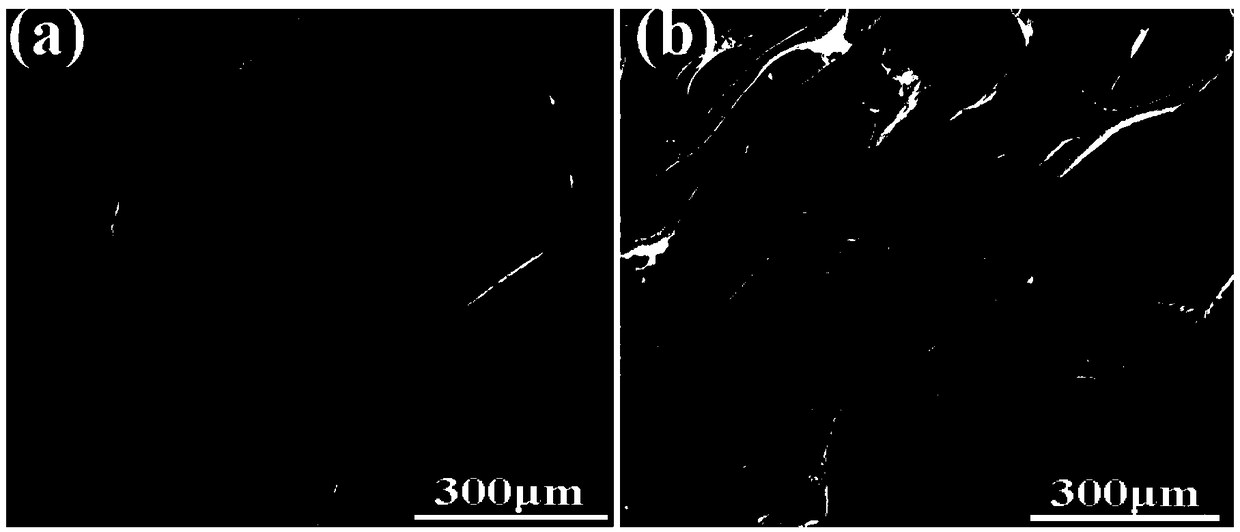

[0020] Step 1. Place 50 mg of silicon dioxide particles with a diameter of about 200 nm in 30 mL of 50 mM tris (Tris) buffer solution with a pH value of 7.8 (that is, the silicon dioxide particles and tris The mass ratio of methane is 1:3.6), ultrasonication for 20 minutes, and standing for 20 minutes. Weigh 24mL of the above solution, and add 3mL of 20mg mL to this solution successively -1 tannic acid solution and 3mL of 10mg mL -1 Silver nitrate solution (that is, the mass ratio of silicon dioxide to tannic acid to silver nitrate is 4:6:3), soak 4 polyurethane sponges (1*1*1cm) in the solution, stir at room temperature for 2 hours, and take out the polyurethane The sponge was washed 3 times with deionized water, then washed 3 times with ethanol, and dried to obtain a polyurethane sponge with a micro-nano structure on the surface.

[0021] Step 2. Put the four polyuret...

Embodiment 2

[0023] Embodiment 2: the preparation of superhydrophobic polyurethane sponge, the steps are as follows:

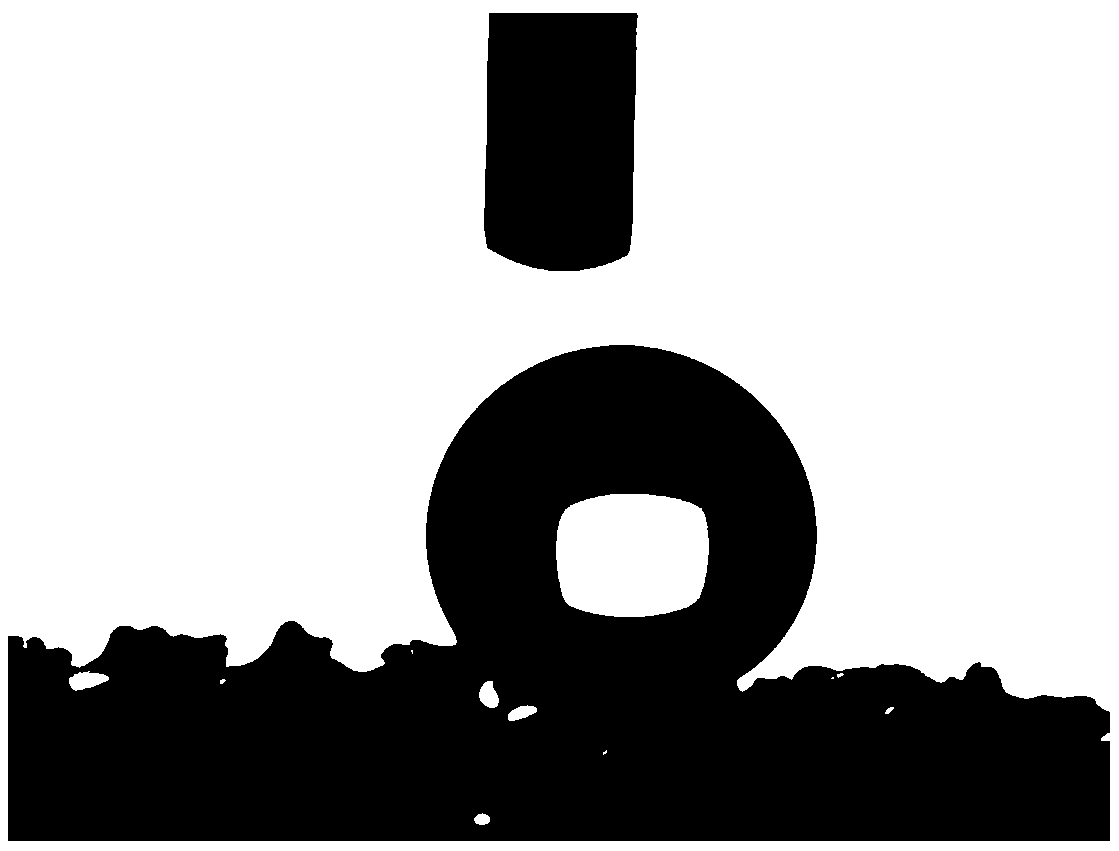

[0024] The steps of this Example 2 are basically the same as those of Example 1, except that in Step 1, the quality of the silicon dioxide particles added is changed from 50 mg to 25 mg (that is, the silicon dioxide particles and trishydroxymethylaminomethane The mass ratio of silicon dioxide to tannic acid to silver nitrate is 2:6:3). Figure 4 It is the water contact angle (CA) photo of the superhydrophobic polyurethane sponge prepared in embodiment 2. After being modified with silica particles, the roughness of the polyurethane sponge surface is increased. When the concentration of silica increased, the water contact angle of the obtained superhydrophobic polyurethane sponge increased, and the water contact angle was 154.32o at this time.

Embodiment 3

[0025] Embodiment 3: the preparation of superhydrophobic polyurethane sponge, the steps are as follows:

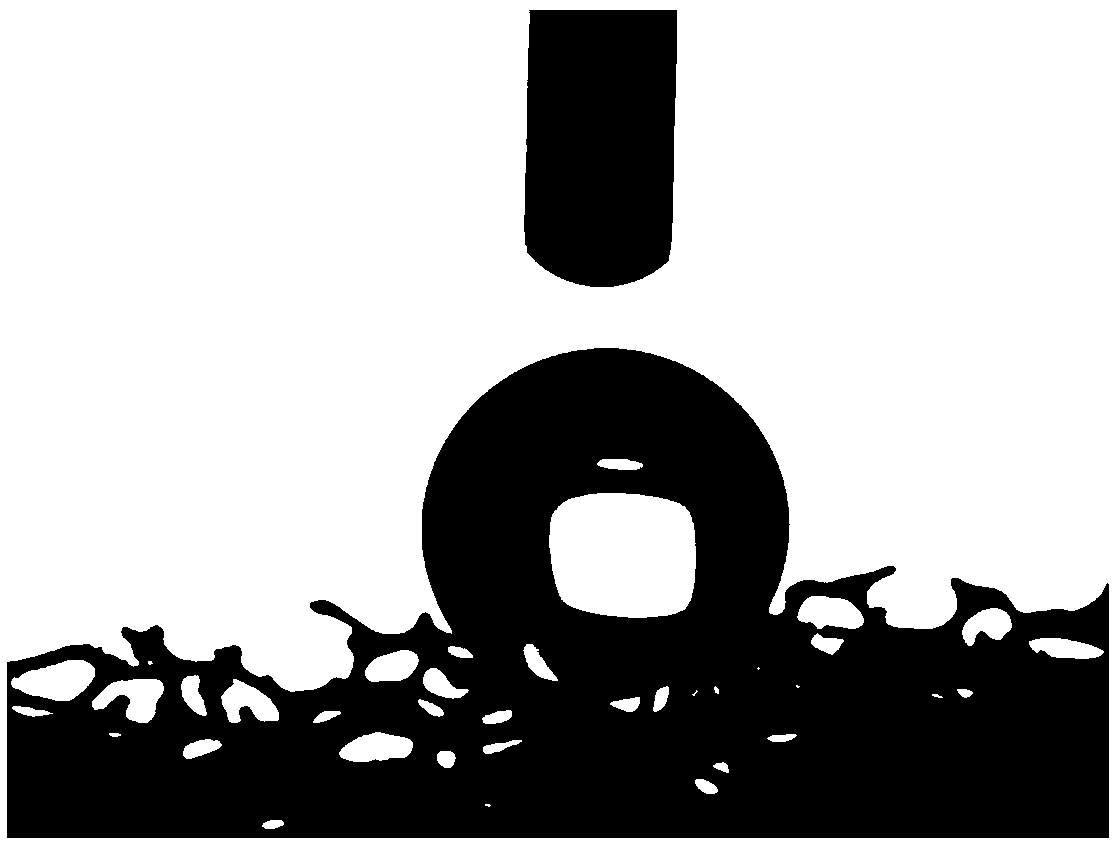

[0026] The steps of this Example 3 are basically the same as those of Example 1, except that in Step 1, the quality of the silicon dioxide particles added is changed from 50 mg to 75 mg (that is, the silicon dioxide particles and trishydroxymethylaminomethane The mass ratio of silicon dioxide to tannic acid to silver nitrate is 2:2:1). Figure 5 The water contact angle (CA) photo of the superhydrophobic polyurethane sponge prepared for embodiment 3. When the concentration of silica increases, the degree of micro-nano structure on the surface of the polyurethane sponge increases, making its roughness increase, the water contact angle of the obtained superhydrophobic polyurethane sponge increases, and the water contact angle is 167.78o at this time.

[0027] In summary, through the above examples and comparative examples and their corresponding water contact angle diagrams,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com