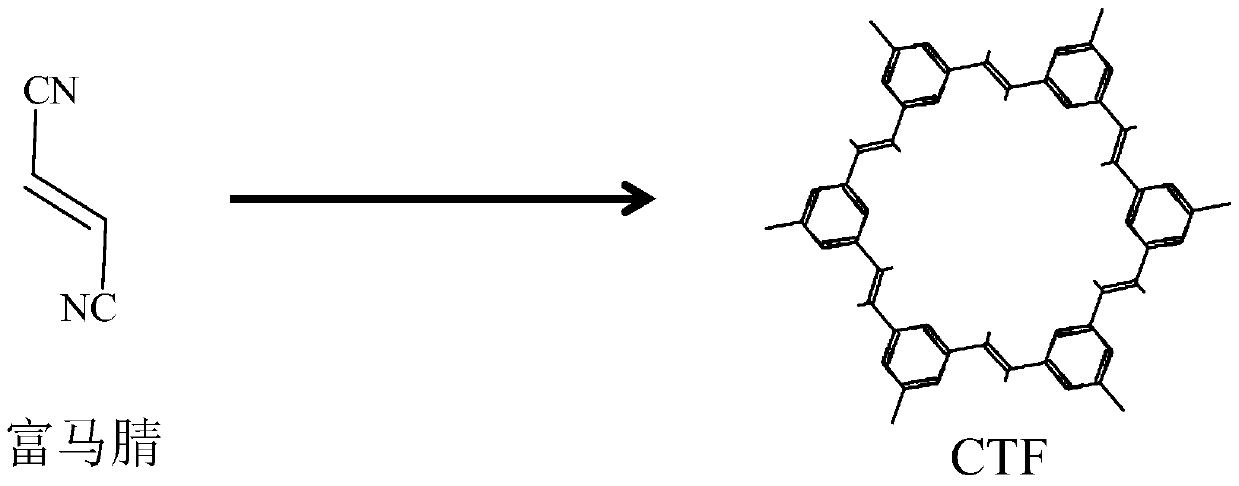

an excellent co 2 Ultramicroporous covalent triazine framework material with adsorption and separation properties and preparation method

A covalent triazine skeleton and ultra-microporous technology, which is applied in the field of preparation of nanoporous materials, can solve the problems of poor selectivity of adsorbents, and achieve the effects of high selectivity, cheap raw materials, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

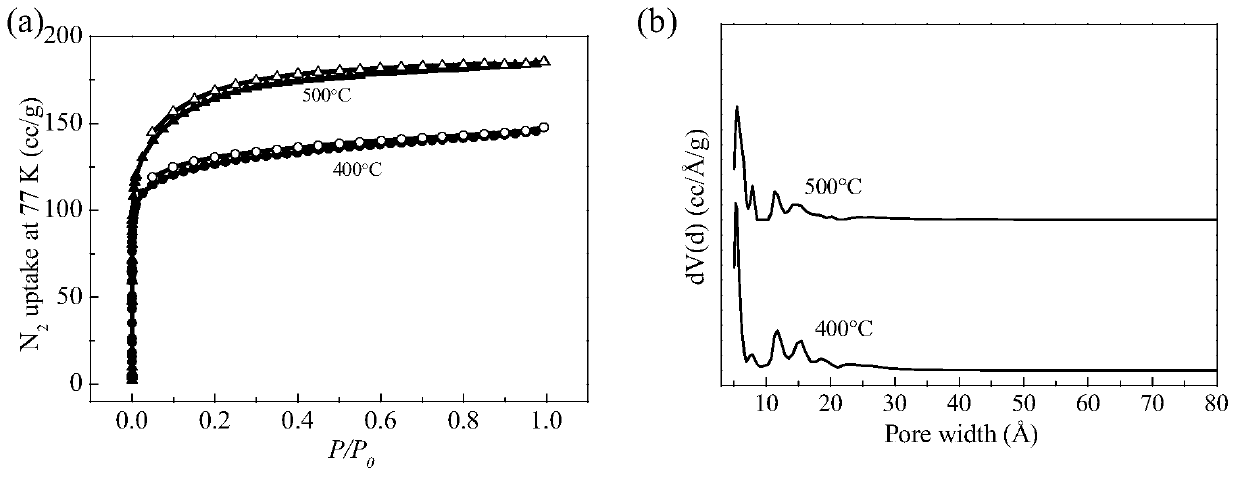

[0028] Example 1 Preparation of covalent triazine framework material

[0029] Mix 0.6g (7.7mmol) monomer fumaronitrile and 2.1g (15.4mmol) zinc chloride evenly, put into an ampoule, and vacuum seal. Heat in a tube furnace at 10°C / min to 350°C and hold at this temperature for 40h, then cool to room temperature. The obtained product was ground, washed with water and dilute hydrochloric acid to remove metal salts, washed with water and methanol three times, and dried under vacuum at 150°C to obtain a black solid.

Embodiment 2

[0030] Example 2 Preparation of covalent triazine framework material

[0031] Mix 0.6g (7.7mmol) monomer fumaronitrile and 2.1g (15.4mmol) zinc chloride evenly, put into an ampoule, and vacuum seal. Heated in a tube furnace at 10 °C / min to 400 °C and held at this temperature for 40 h, then cooled to room temperature. The obtained product was ground, washed with water and dilute hydrochloric acid to remove metal salts, washed with water and methanol three times, and dried under vacuum at 150°C to obtain a black solid.

Embodiment 3

[0032] Example 3 Preparation of covalent triazine framework material

[0033] Mix 0.6g (7.7mmol) monomer fumaronitrile and 2.1g (15.4mmol) zinc chloride evenly, put into an ampoule, and vacuum seal. Heat in a tube furnace at 10 °C / min to 600 °C and hold at this temperature for 40 h, then cool to room temperature. The obtained product was ground, washed with water and dilute hydrochloric acid to remove metal salts, washed with water and methanol three times, and dried under vacuum at 150°C to obtain a black solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com