Montmorillonite modified polyvinyl chloride flat plate hyperfiltration membrane and preparation method thereof

A technology for polyvinyl chloride and polyvinyl chloride powder, applied in the field of membrane separation, can solve the problems of complex preparation process, poor anti-pollution performance, etc., and achieve the effects of improving the retention rate, strong anti-pollution performance, and simplifying the preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

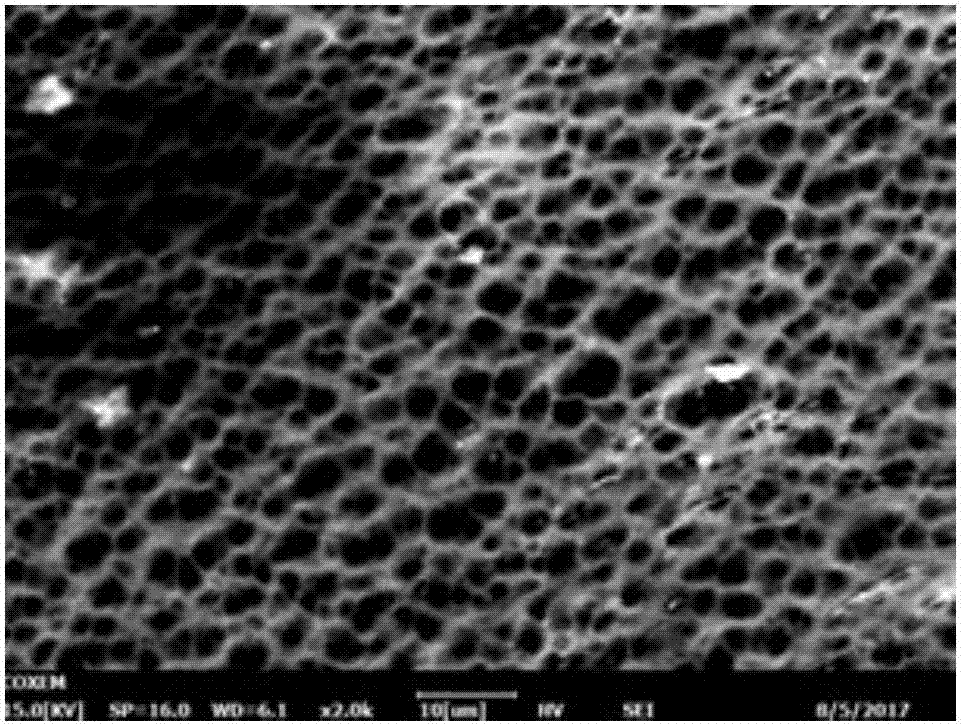

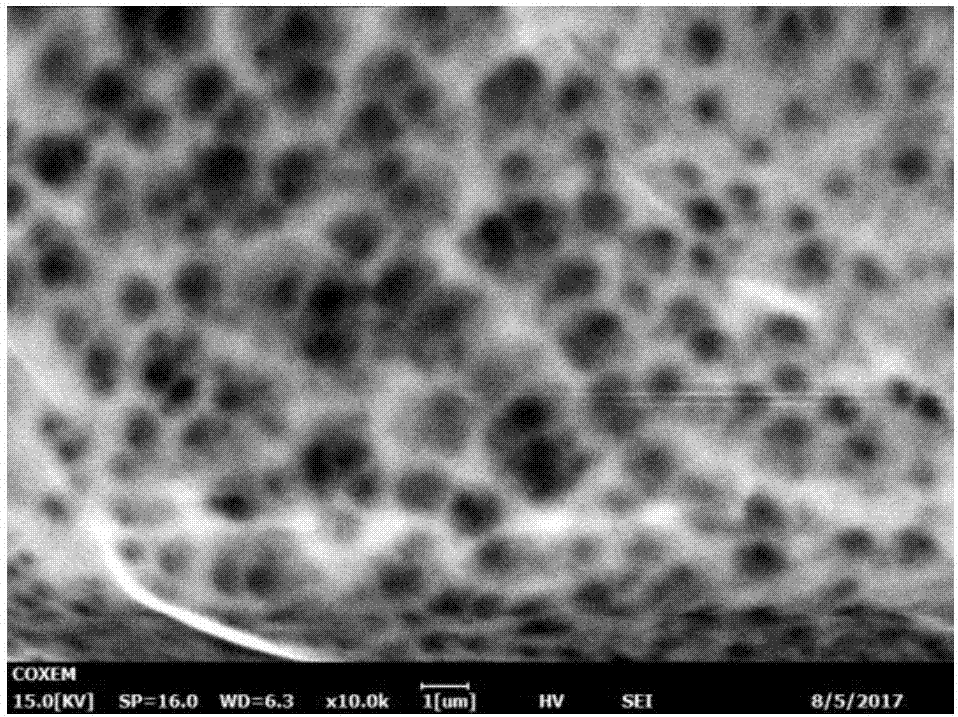

[0040] A montmorillonite-modified polyvinyl chloride flat ultrafiltration membrane is formulated with montmorillonite hydrophilic-modified polyvinyl chloride to form a casting solution, which is separated by defoaming, coating and solidification; the casting solution includes The following components in mass percent:

[0041] PVC 10%

[0042] Montmorillonite 0.3%

[0043] Molecular weight 400 polyethylene glycol 3%

[0044] The balance is N,N-dimethylacetamide.

[0045] Wherein, the montmorillonite is modified, and the modification method includes the following steps:

[0046] 1) Mix montmorillonite and lauryl amidopropyl hydroxysultaine with a mass ratio of 0.7:1, heat to 60° C., and stir and react at a speed of 1600 rpm for 5 hours;

[0047] 2) Filter the reacted product, and then dry it at 65°C for 24 hours;

[0048] 3) adding the dried product into a ball mill, passing through a 180-mesh sieve after crushing to obtain a modified montmorillonite.

[0049] A preparatio...

Embodiment 2

[0056] A montmorillonite-modified polyvinyl chloride flat ultrafiltration membrane is formulated with montmorillonite hydrophilic-modified polyvinyl chloride to form a casting solution, which is separated by defoaming, coating and solidification; the casting solution includes The following components in mass percent:

[0057] PVC 13%

[0058] Montmorillonite 0.5%

[0059] Molecular weight 400 polyethylene glycol 4%

[0060] The balance is N,N-dimethylacetamide.

[0061] Wherein, the montmorillonite is modified, and the modification method includes the following steps:

[0062] 1) Mix montmorillonite and lauryl amidopropyl hydroxysultaine with a mass ratio of 0.8:1, heat to 63° C., and stir and react at a speed of 1700 rpm for 5.3 hours;

[0063] 2) Filter the reacted product, and then dry it at 70°C for 30 hours;

[0064] 3) adding the dried product into a ball mill, passing through a 190-mesh sieve after crushing to obtain a modified montmorillonite.

[0065] A preparat...

Embodiment 3

[0072] A montmorillonite-modified polyvinyl chloride flat ultrafiltration membrane is formulated with montmorillonite hydrophilic-modified polyvinyl chloride to form a casting solution, which is separated by defoaming, coating and solidification; the casting solution includes The following components in mass percent:

[0073] PVC 15%

[0074] Montmorillonite 0.7%

[0075] Molecular weight 600 polyethylene glycol 5%

[0076] The balance is N,N-dimethylacetamide.

[0077] Wherein, the montmorillonite is modified, and the modification method includes the following steps:

[0078] 1) Mix montmorillonite and lauryl amidopropyl sulfobetaine with a mass ratio of 0.85:1, heat to 65° C., and stir and react at a speed of 1800 rpm for 5.5 hours;

[0079] 2) Filter the reacted product, and then dry it at 75°C for 35 hours;

[0080] 3) adding the dried product into a ball mill, passing through a 200-mesh sieve after crushing to obtain a modified montmorillonite.

[0081] A preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com