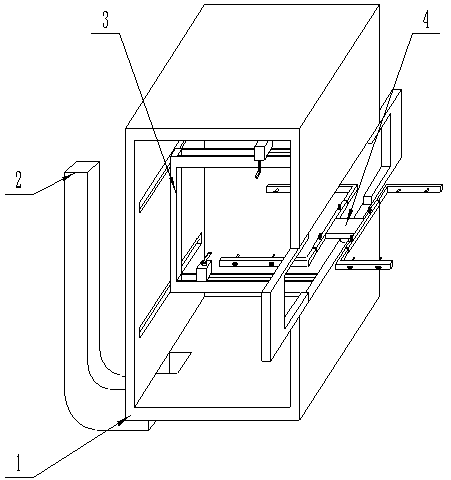

Paint spraying equipment for wooden door processing

A technology for painting equipment and wooden doors, applied in painting rooms, spraying devices, etc., can solve the problems of human harm, waste of time, inconvenient operation, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

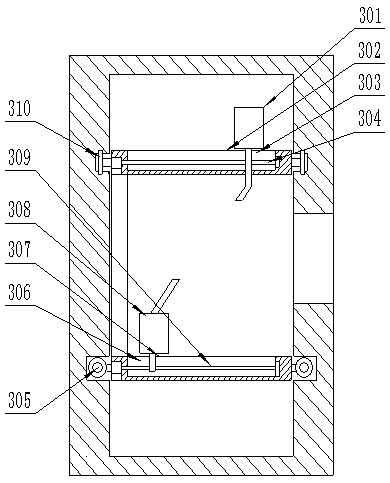

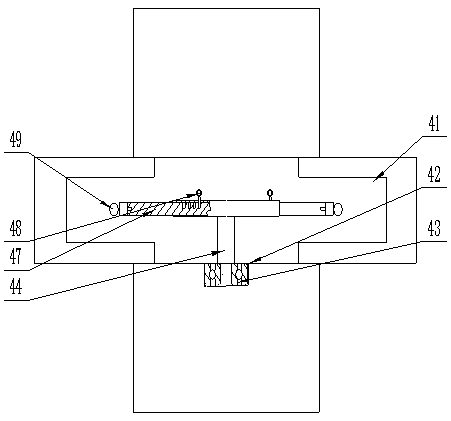

[0025]Specific implementation: during use, the user operates the spray paint conveying device, and the spray paint conveying device conveys the spray paint to the upper spray head 301 and the lower spray head 308 through the conduit, and the upper spray head 301 and the lower spray head 308 spray paint. When the equipment is running stably, use The personnel rotate the wooden door fixed on the rotating frame 4 to the spraying room 1 for spraying, so that the circuit of the micro motor 2 and the external power supply is connected, and the rotation of the micro motor 2 drives the upper screw 304 to rotate, so that the ball screw nut pair 2 Under the action, the rotary motion of the upper screw rod 304 is converted into a linear motion, and then the ball nut seat 2 drives the upper nozzle 301 to move, so that the circuit between the micro motor 3 and the external power supply is connected, and the rotation of the micro motor 3 drives the lower screw rod 309 to rotate, thereby Unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com