Two-section flexible operation arm

A two-stage, manipulator technology, applied in the field of flexible manipulators, can solve the problems of limited range of motion, poor flexibility, cumbersomeness, etc., and achieve the effect of large range of motion, strong environmental adaptability, and flexible motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

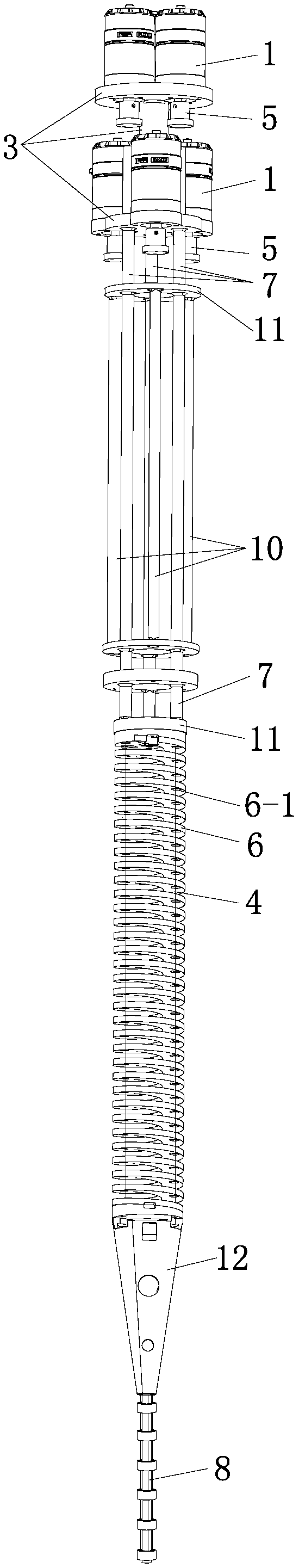

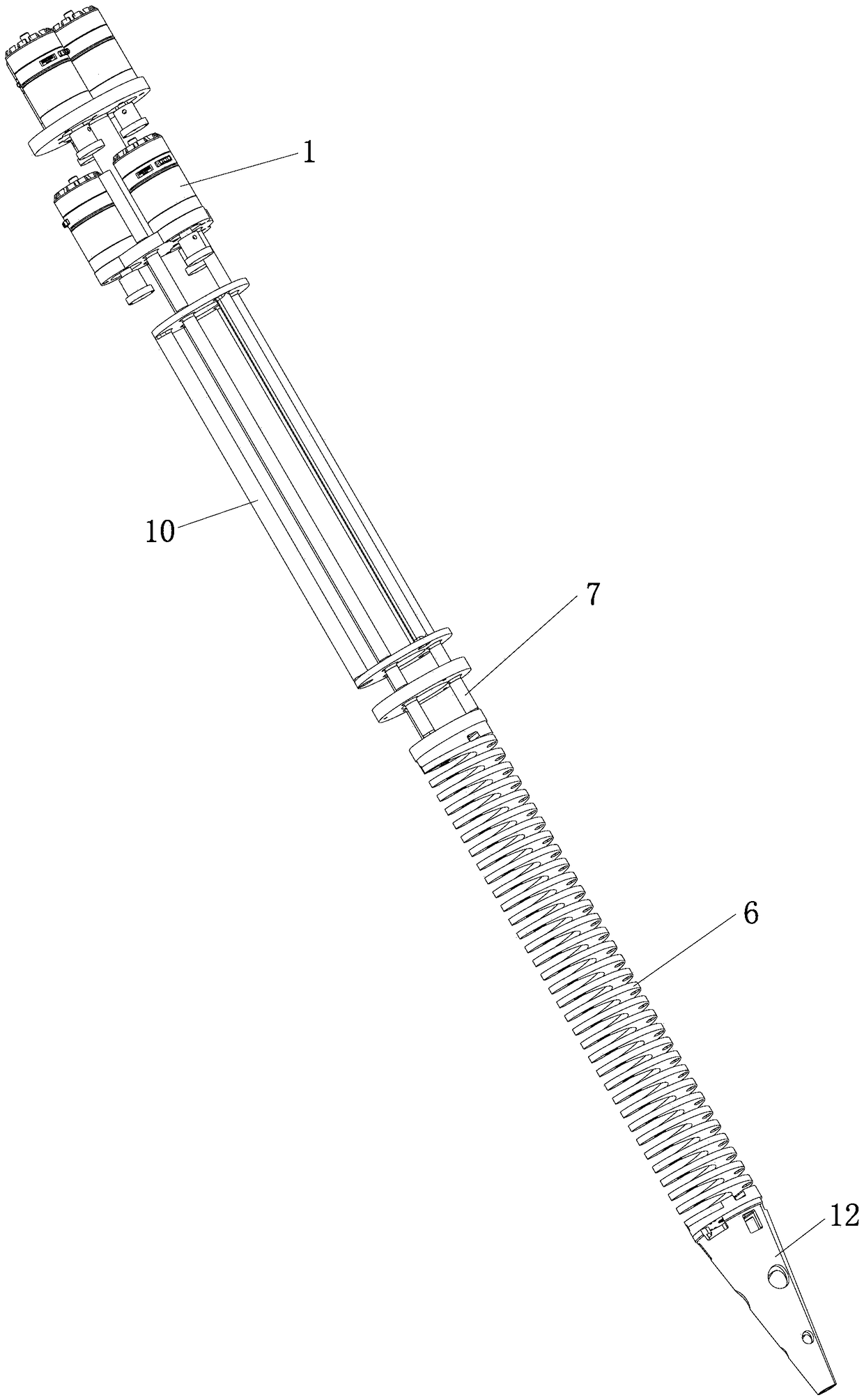

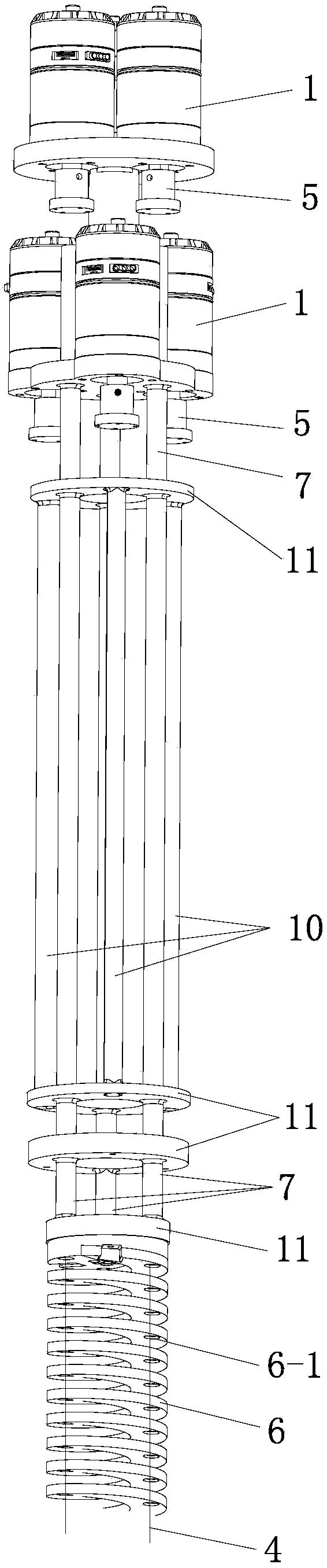

[0022] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

[0023] A two-section flexible operating arm, which includes two sets of power sources, a power source conjoined fixing frame 3, a first section of flexible arm 6 and a second section of flexible arm 8;

[0024] Two groups of power sources are arranged on the power source conjoined fixing frame 3, each group of power sources includes three motors 1, and the three motors 1 are evenly arranged, and the output end of each motor 1 is fixedly equipped with a connection plate 5,

[0025] The first section flexible arm 6 is a helical spring, and one end of the first section flexible arm 6 is connected with the fixed frame of the power source, and the other end of the first section flexible arm 6 is connected with an end of the second section flexible arm 8, and the second section The flexible arm 8 is an elastic telescopic flexible arm; three g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com