Manufacturing method for rotational molding car roof box and rotational molding car roof box

A technology of rotomolding and manufacturing methods, which is applied in the field of rotomolding roof boxes and rotomolding roof boxes, and can solve the problems of being unable to move, heavy roof boxes, and difficult to operate by a single person. Achieve the effect of avoiding driving hazards and reducing manufacturing and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

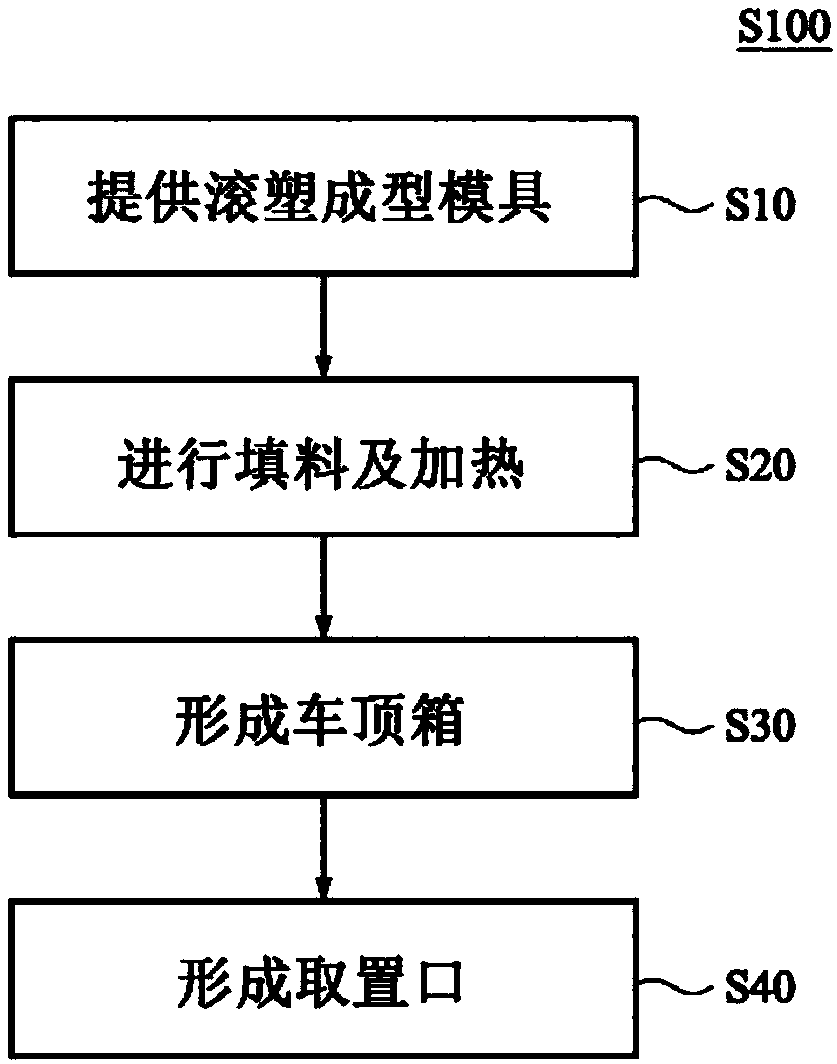

[0064] Please refer to as figure 1 As shown, it is a manufacturing method S100 of a rotational molding roof box of the embodiment, which includes the following steps: providing a rotational molding mold (step S10); performing filling and heating (step S20); forming a roof box (step S30); and forming a pick-and-place opening (step S40).

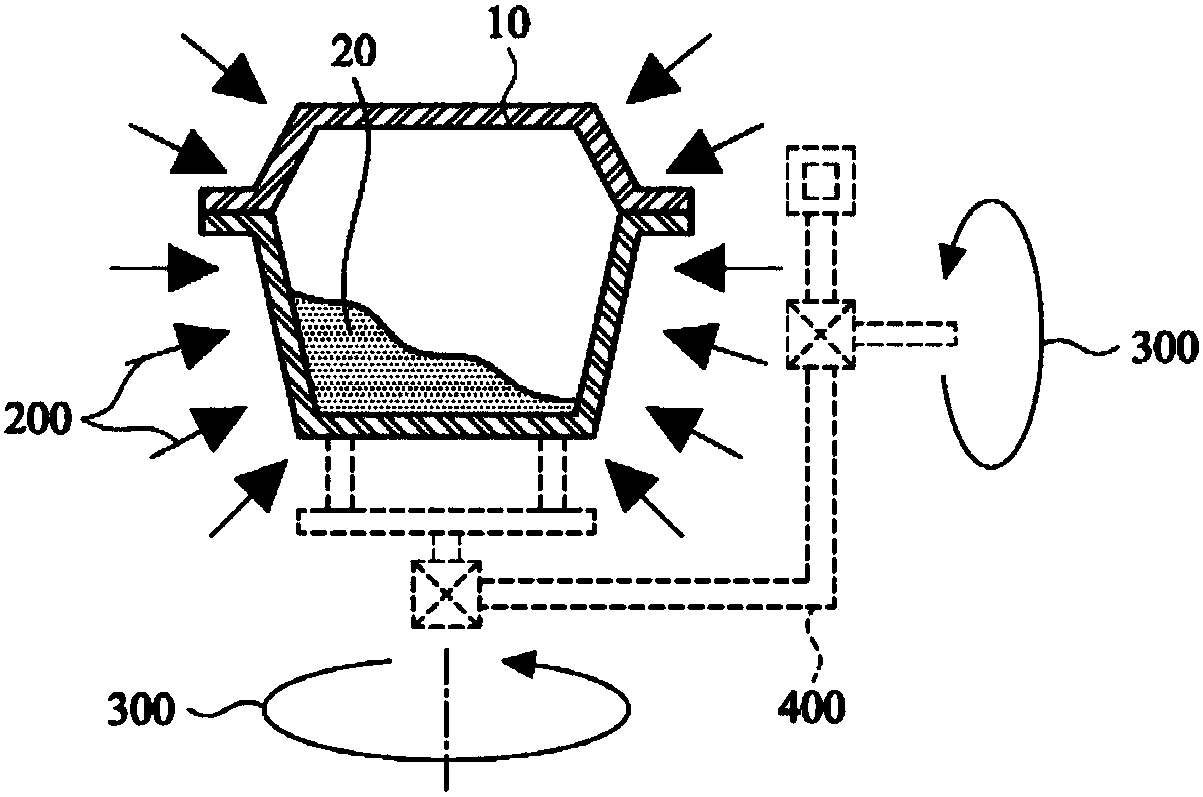

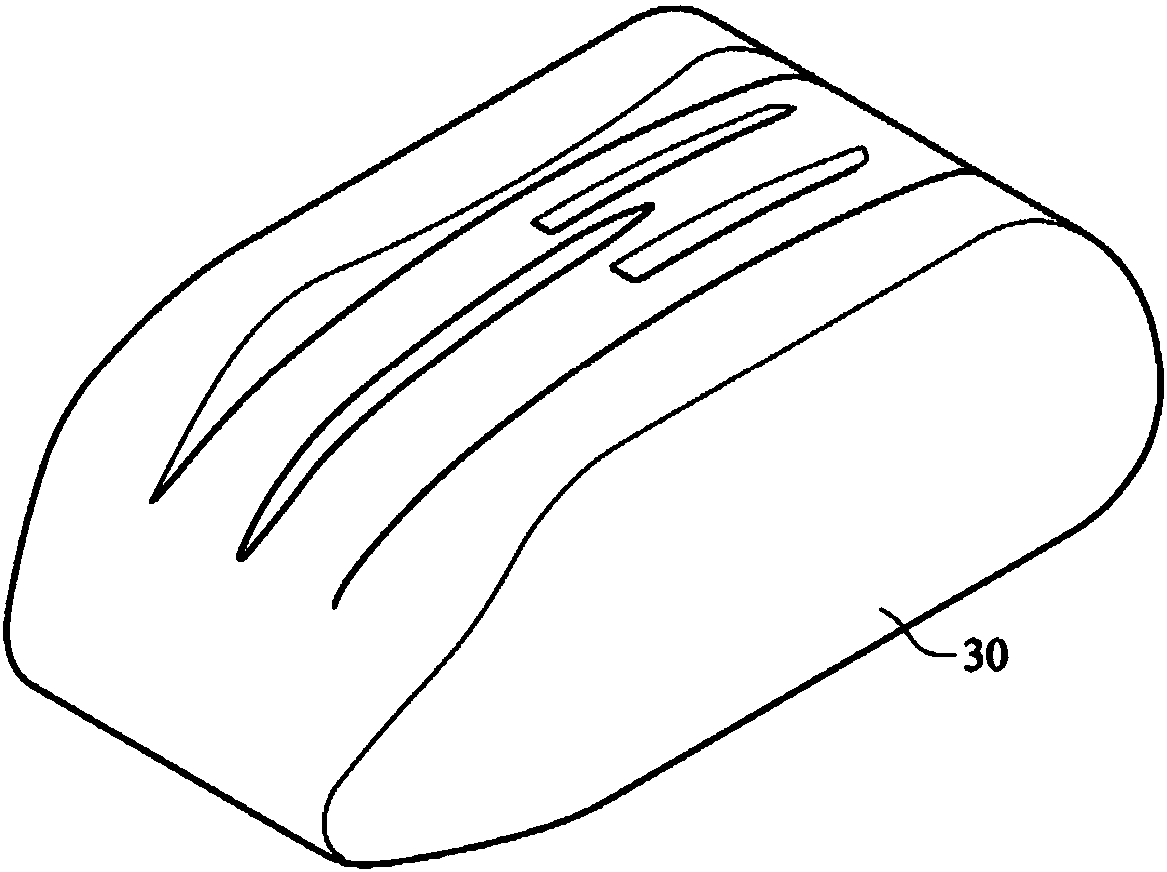

[0065] like figure 1 , figure 2 and Figure 3A As shown, providing a rotational molding mold (step S10 ) is to use the rotational molding mold 10 to manufacture the roof box 30 , wherein the rotational molding mold 10 is an openable three-dimensional rotational molding mold.

[0066] Please refer to as figure 1 , figure 2 As shown in the figure, filling and heating are carried out (step S20), which is to fill the plastic 20 into the rotational molding mold 10, and close the rotational molding mold 10 and heat from the outside of the rotational molding mold 10, so that the plastic is evenly attached to the The inner surface of the rotom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com