A kind of rosin imidazoline quaternary ammonium salt compound, corrosion inhibitor and preparation method

A technology of quaternary ammonium salt compound, rosin imidazoline, which is applied in the field of corrosion inhibitor and its preparation, and the field of rosin imidazoline quaternary ammonium compound, which can solve problems such as cumbersome recovery and utilization of condensate oil, reduced anti-corrosion effect, localized corrosion, etc., and achieves Good water phase anti-corrosion effect, enhanced adsorption capacity, and reasonable distribution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a second aspect, the embodiments of the present invention provide a method for preparing the above-mentioned rosin imidazoline quaternary ammonium salt compound, and the specific steps are as follows:

[0037] Step 101: Add abietic acid, diethylenetriamine and water-carrying agent to the reaction vessel, carry out dehydration reaction at 160-180°C for 2-2.5 hours, then raise the temperature to 200-240°C, and carry out cyclization reaction for 3-4 hours , heat and steam the water in the cyclization reaction product, and obtain rosin imidazoline after cooling.

[0038] Wherein, the molar ratio of abietic acid to diethylenetriamine is 1: (1.1-1.2); the water-carrying agent is 20-30% of the total mass of abietic acid and diethylenetriamine.

[0039] Step 102. Raise the temperature of rosin imidazoline to 70-90°C, drop diisooctyl phosphate, mix well, then raise the temperature to 120-130°C, react for 2-2.5 hours, and finally cool the reaction product to obtain rosin imida...

Embodiment 1

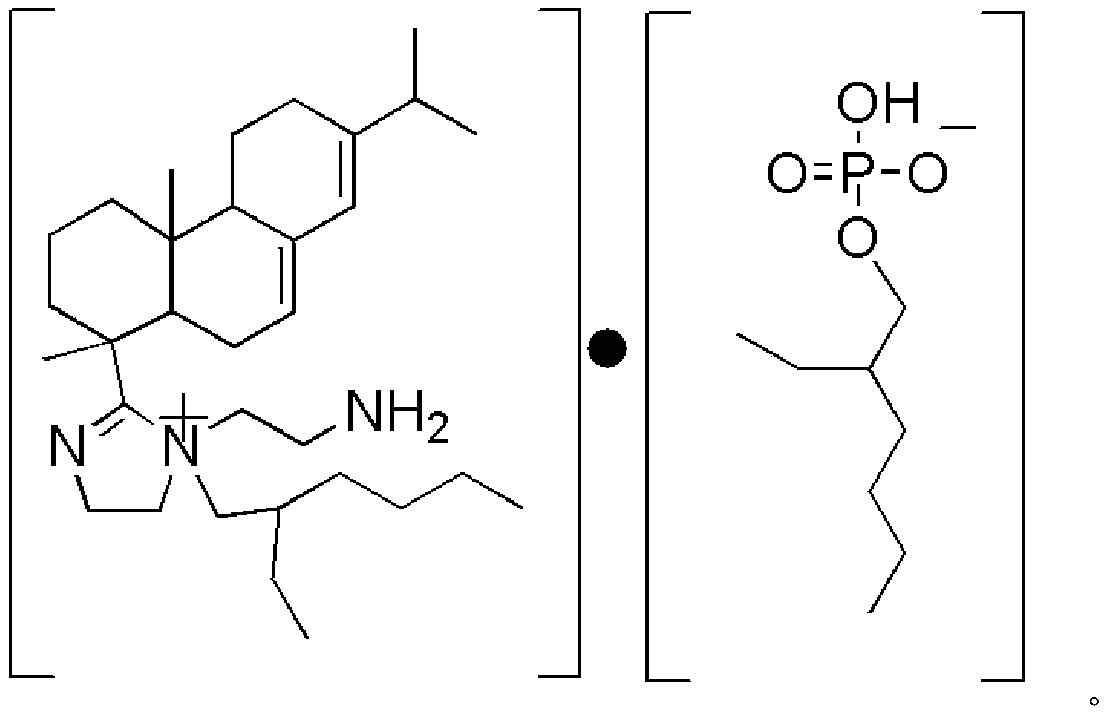

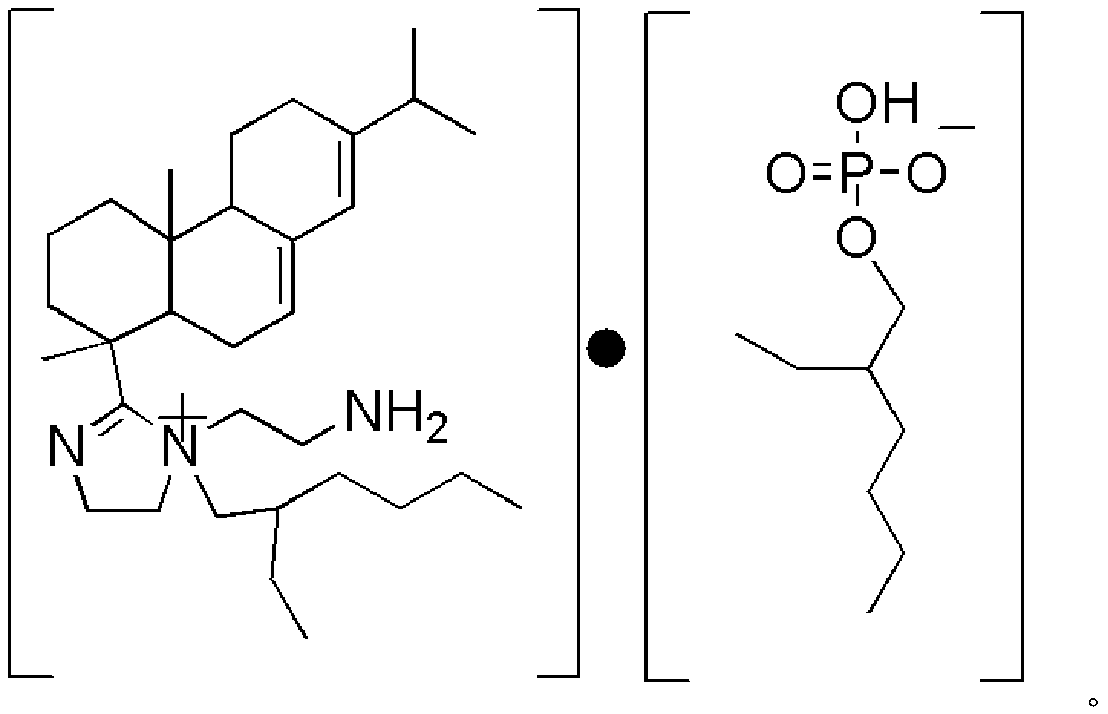

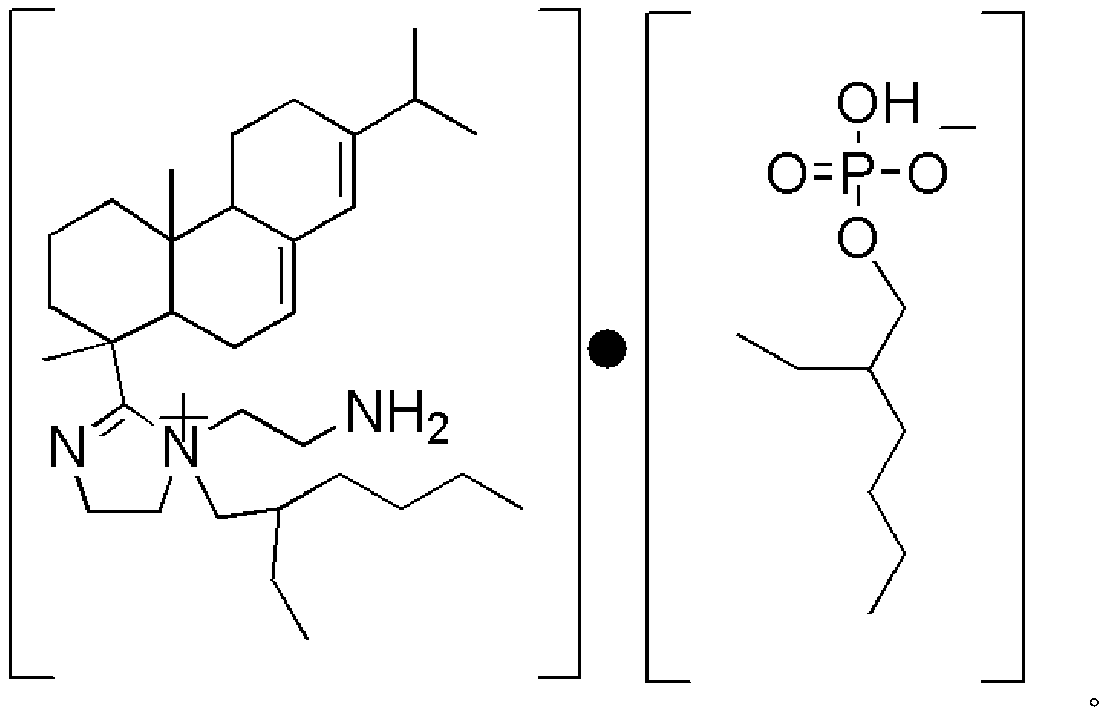

[0070] The present embodiment provides a kind of rosin imidazoline quaternary ammonium salt compound, and its chemical structural formula is:

[0071]

[0072] If this rosin imidazoline quaternary ammonium compound is prepared by the following method:

[0073] Step (1), prepare rosin imidazoline

[0074] Into a four-neck flask equipped with a stirrer, thermometer, water separator, condenser and nitrogen protection, add 0.5 mol of abietic acid, 0.6 mol of diethylenetriamine and 50 g of xylene in sequence, and react at 180°C for 2 hours. Then, the temperature was gradually raised to 220°C, and the reaction was carried out at this temperature for 4h. Finally, cool to room temperature to get rosin imidazoline.

[0075] Step (2), prepare rosin imidazoline quaternary ammonium compound

[0076] The above-mentioned rosin imidazoline was gradually heated up to 80° C., and then 0.65 moles of diisooctyl phosphate was gradually added into the four-necked flask to mix the components ...

Embodiment 2

[0078] This embodiment provides a kind of metal corrosion inhibitor, and this metal corrosion inhibitor comprises the following components by weight percentage:

[0079] 23 parts of rosin imidazoline quaternary ammonium salt compound prepared in Example 1, 2 parts of surfactant, 5 parts of auxiliary agent, 0.1 part of demulsifier, and the balance is mineral spirits.

[0080] The metal corrosion inhibitor is prepared by the following method:

[0081] In step , 1 g of demulsifier and 99 g of mineral spirits were stirred evenly at room temperature to obtain a concentrated solution of demulsifier, and the concentrated solution was 1% by weight.

[0082] Step , take 10g of the above demulsifier concentrate and dilute it with 60g of mineral spirits to obtain the diluted demulsifier solution.

[0083] Step , add 23g of rosin imidazoline quaternary ammonium compound to the diluted demulsifier solution, stir evenly at 40°C with a stirring speed of 150rpm, then cool to room temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com