Glove machine needle drum worm structure

A technology of glove machine and worm, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of difficult adjustment and achieve the effects of low maintenance cost, high precision and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

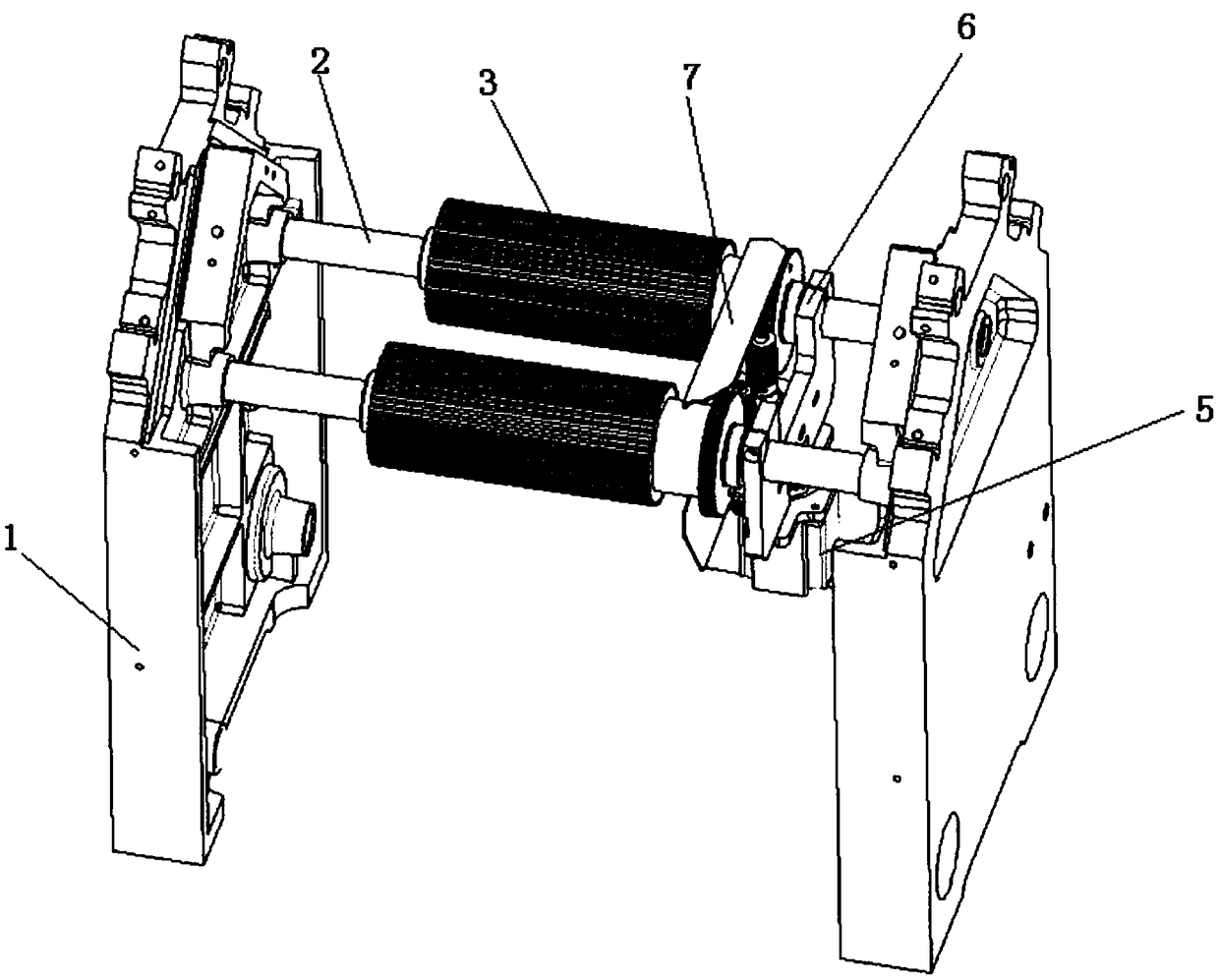

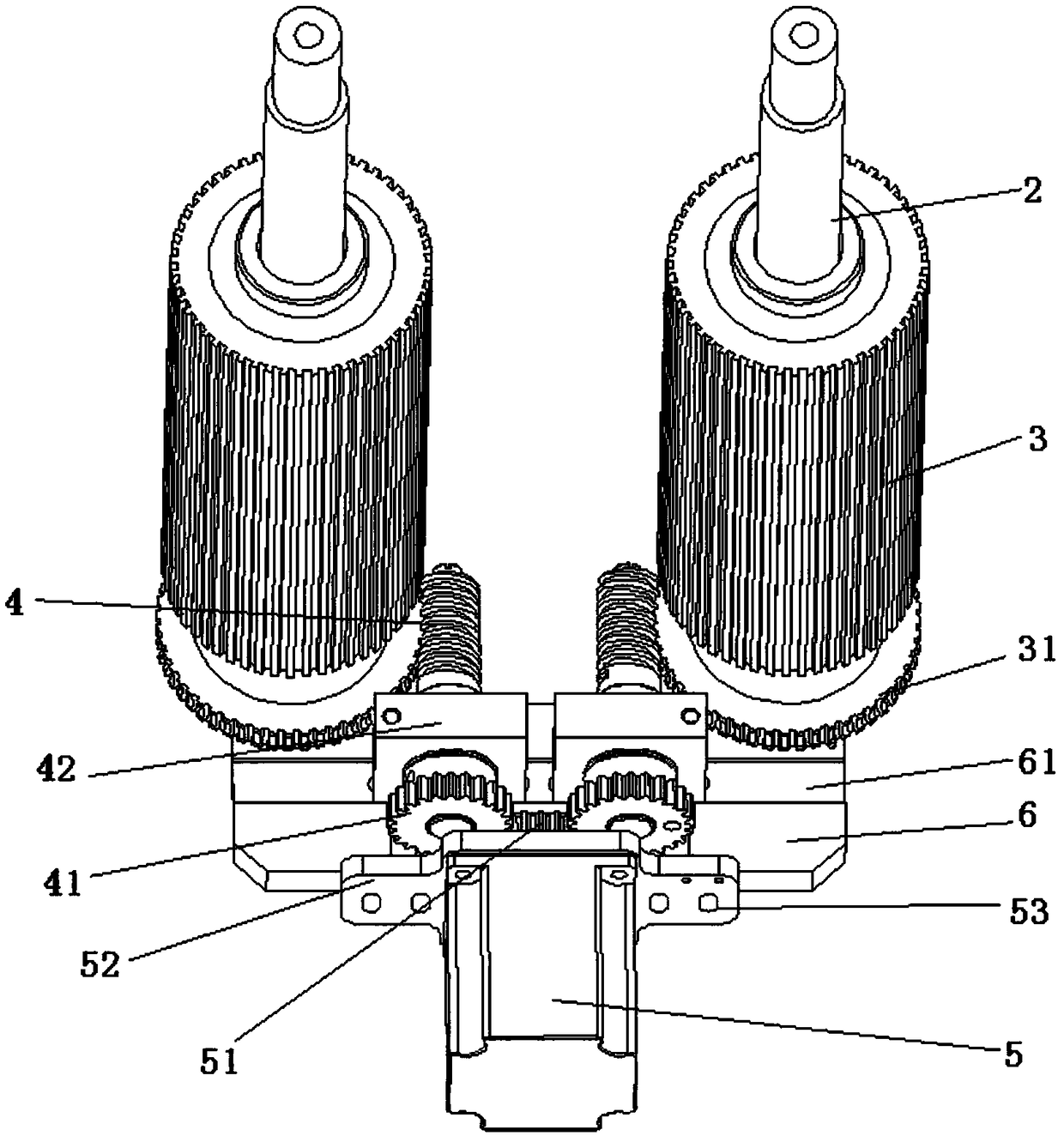

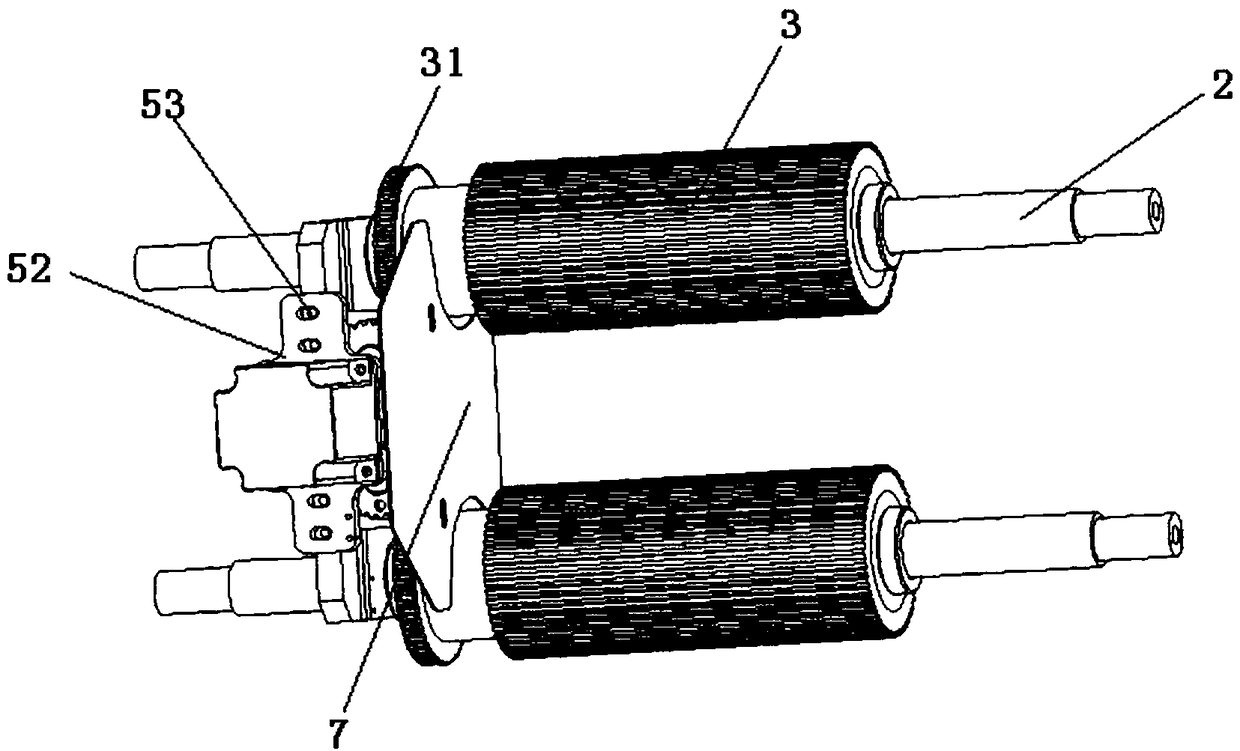

[0021] Combine below Figure 1-5 For further explanation, a glove machine needle drum and worm structure includes two wall panels 1, two needle drums 3, two worms 4, a motor 5, two worm gears 41, motor gears 51, and two worm seats 42 and base plate 6, fixed shaft 2 is installed on wall plate 1, needle drum 3 is installed on fixed shaft 2 through bearing 43, worm gear 31 is installed on needle drum 3, base plate 6 is installed on fixed shaft 2, motor base plate 52 is provided with The second chute 53, the motor bottom plate 52 and the bottom plate 6 are slidably connected through the second chute 53, the setting of the second chute 53 enables the motor 5 to move back and forth, that is, the motor gear 51 can move back and forth to compress the worm gear 41, when After adjustment, use screws to fix the motor bottom plate 52 on the bottom plate 6; the motor 5 is provided with a motor shaft, the motor shaft is provided with a motor gear 51, and the bottom plate 6 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com