Two-section type pipe thread sealing structure

A technology of sealing structure and pipe thread, which is applied in the field of pipe thread sealing, which can solve the problems such as complicated reapplying sealant process, difficulty for users to reapply sealant, and thread sealant is easy to fall off, etc., so as to achieve reliable sealing connection effect and simple maintenance process Convenient and fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

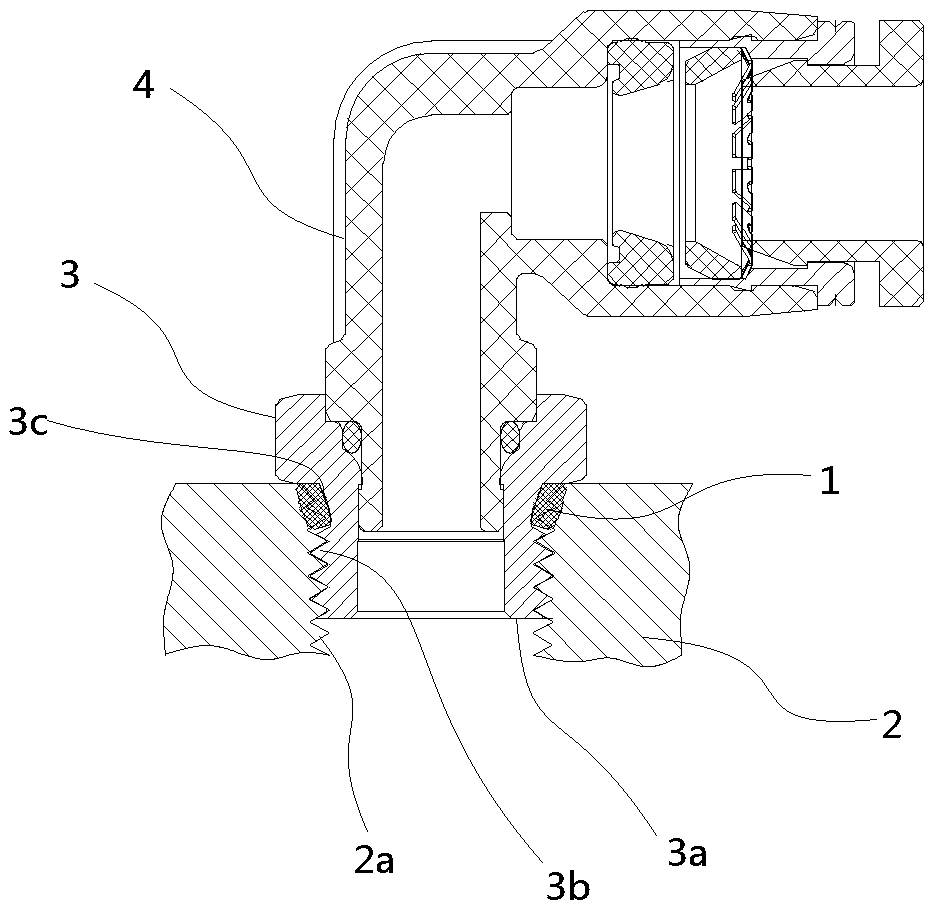

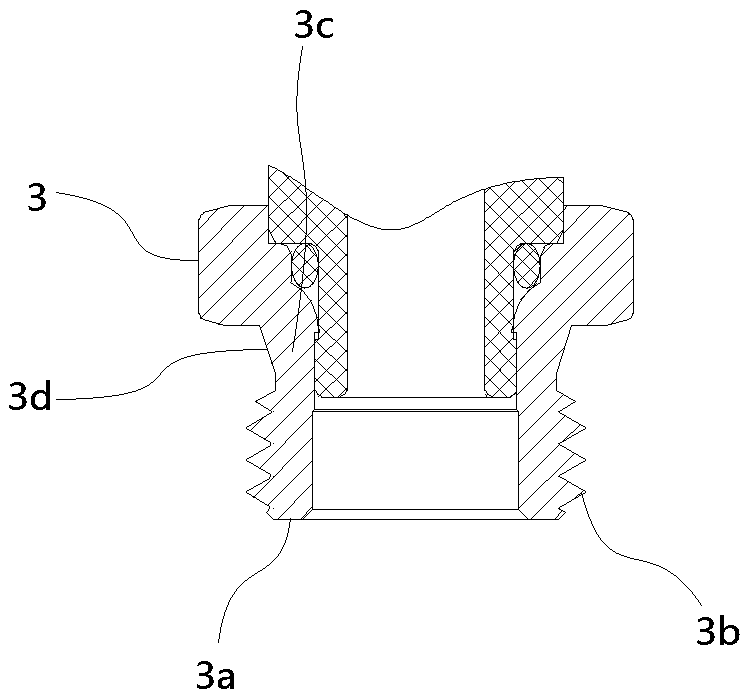

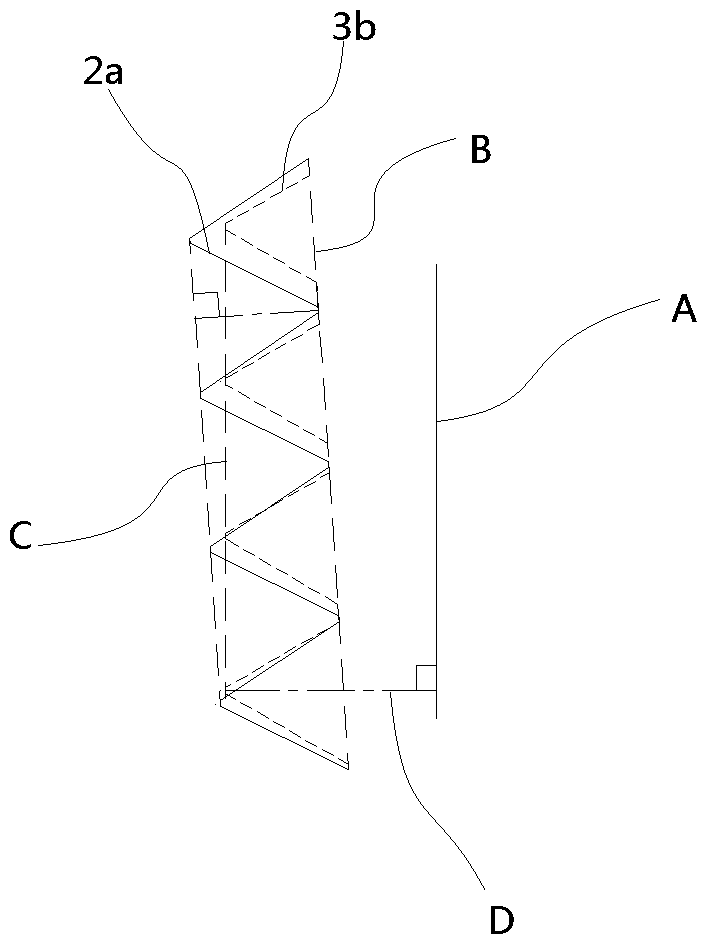

[0026] Such as figure 1 In the shown embodiment, a two-stage pipe thread sealing structure includes a pipe joint 3 and a connection object 2. The upper end of the pipe joint is connected to the pipe 4 to keep the seal between them, and the lower end of the pipe joint is connected to the connection object. combine figure 2 As shown, the pipe joint is provided with an external thread section 3a and a sealing section 3c, and the sealing section is located at the root of the external thread section. There is an external thread 3b on the external thread section, the surface C where the crest of the external thread is in a cylindrical shape, and the surface B where the bottom of the external thread is conical, shrinking from the root of the external thread to the top of the external thread, so the bottom of the external thread The diameter of the circumference where it is located is gradually reduced by the pipe joint.

[0027] The connection object is provided with an internal t...

Embodiment 2

[0032] Based on the structure of the above-mentioned embodiment 1, such as Figure 5 As shown, the upper end surface and the lower end surface of the sealing ring are respectively provided with end surface ribs 11 . During actual use, the inner and outer diameters of the sealing ring rotate due to different friction forces, and then twist and deform. At this time, the end ribs on the upper and lower end faces can simultaneously seal the pipe joint and the connected object to ensure the sealing effect.

Embodiment 3

[0034] The difference between embodiment 3 and embodiment 1 is that, as Image 6As shown, the sealing ring is provided with a closed inner cavity 1b, the inner cavity and the sealing ring are coaxially arranged, the inner cavity is provided with a thread sealant 1c, and the end of the sealing ring facing the external thread section is provided with a number of evenly distributed blind holes 1d, The outer end of the blind hole is provided with a thin-walled layer 1e whose thickness is smaller than that of the end wall of the cavity. When the pipe joint is tightened, the pipe joint squeezes the connected object, extrudes the thread sealant to the internal and external threads, and the thread sealant flows to fill the gap between the internal and external threads, improving the sealing performance of the pipe joint. When the thread sealant falls off after many times of use, the gasket can be replaced after removing the residual glue. After the internal and external threads are ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com