Automatic needle withdrawal assembly

A needle assembly and automatic technology, applied in the direction of needles and instruments introduced into the body, can solve problems such as redness, swelling, excessive outflow, and poor medical experience for patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

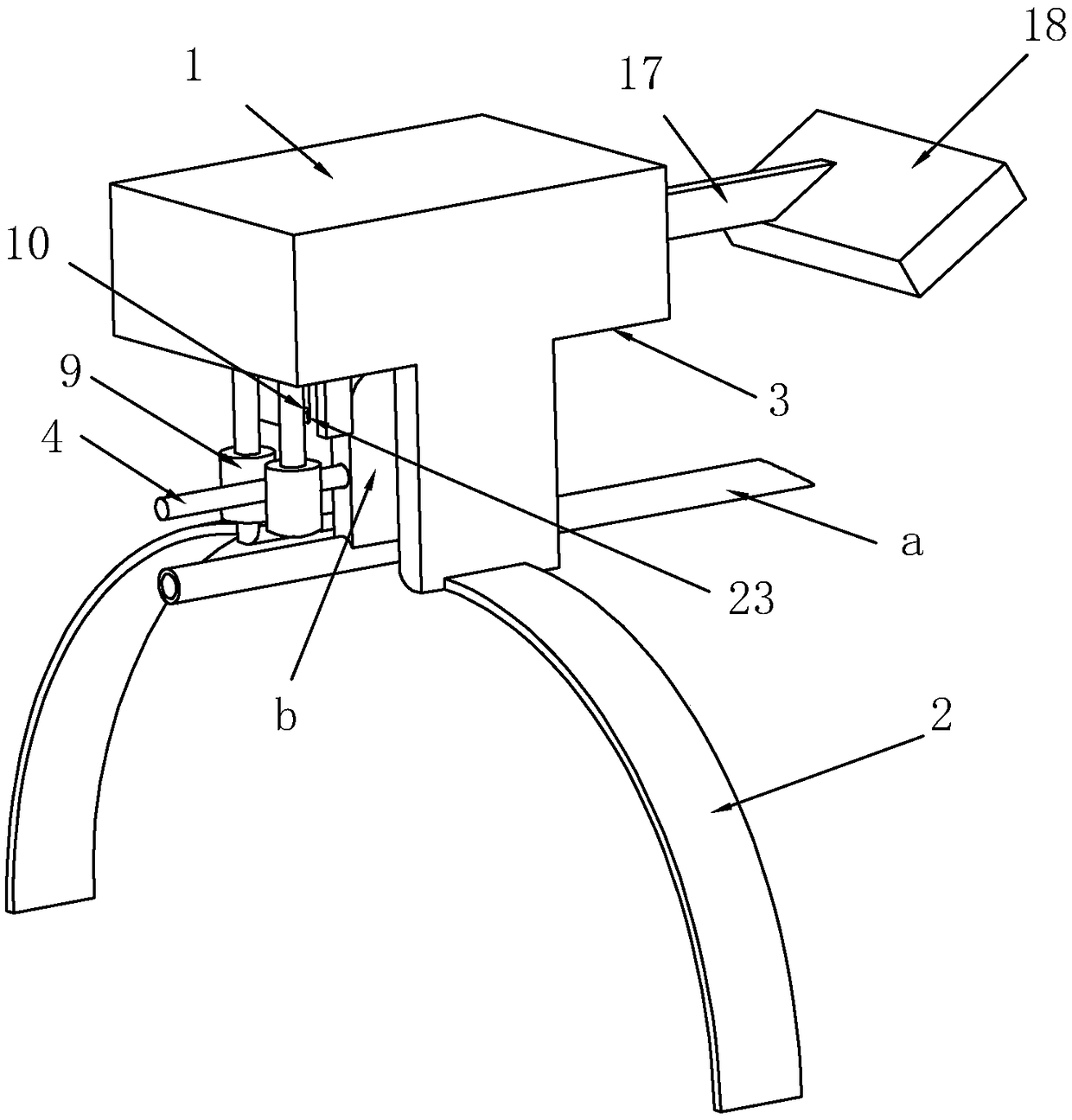

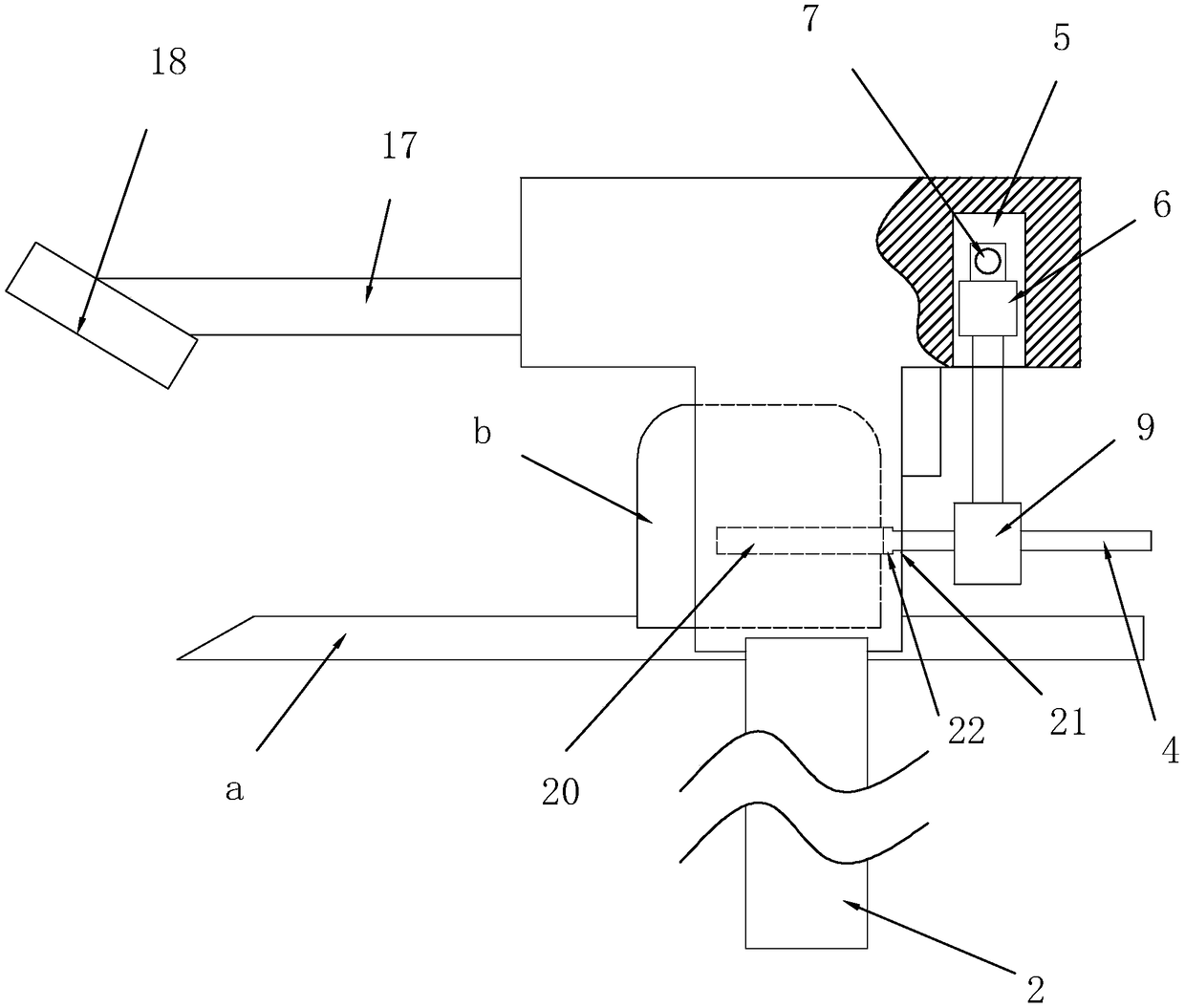

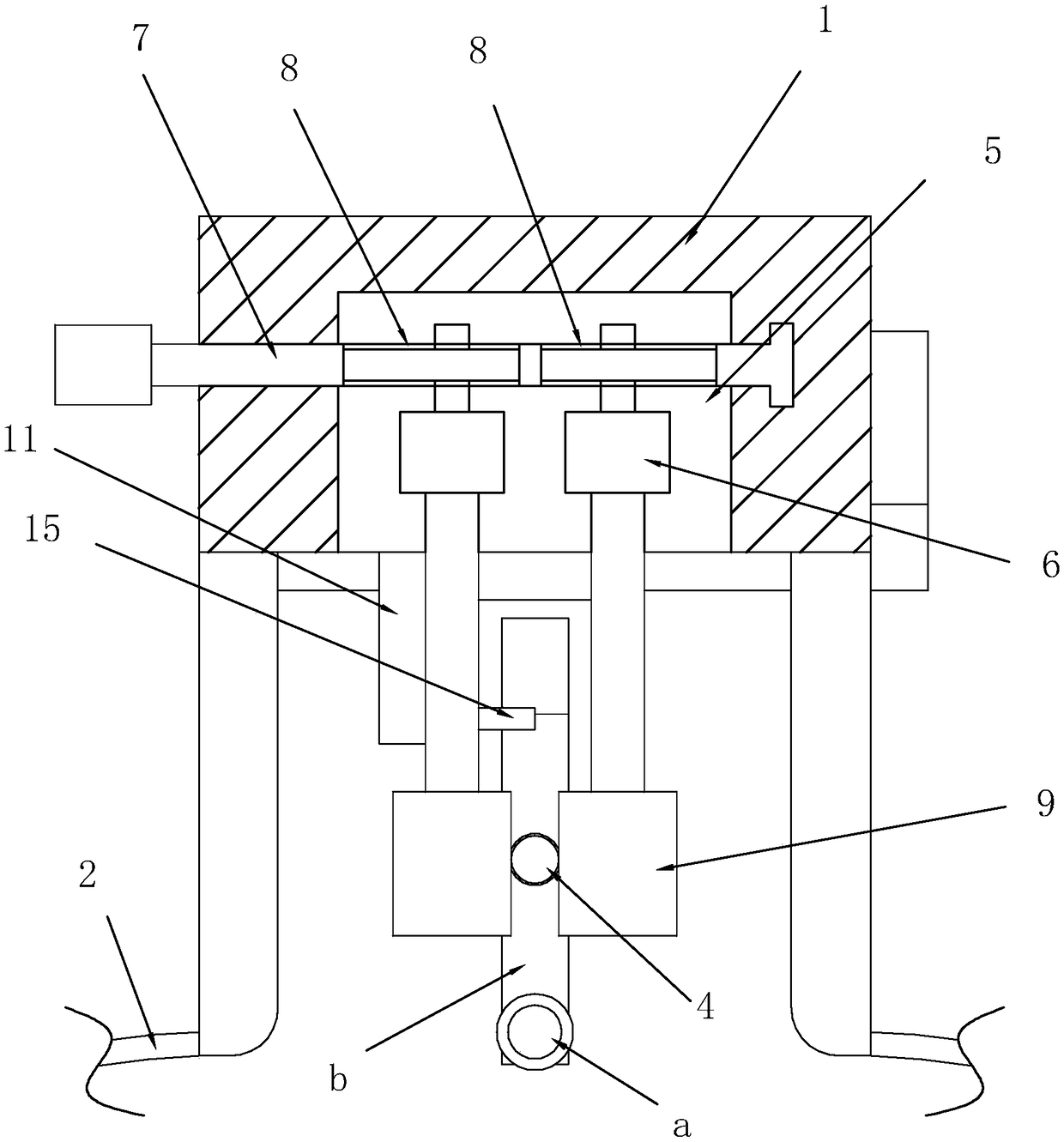

[0030] The following is attached Figure 1-5 The present invention will be described in further detail.

[0031] An automatic needle extraction assembly includes a traditional drip injection head. The drip injection head includes a needle a, a clamping piece b is provided on the needle a, and a sliding hole 20 is provided on the clamping piece b. The direction of the orifice is opposite to the direction of the tip of the needle a. A clamping rod 4 is provided in the sliding hole 20. A first positioning ring 21 is provided at the orifice of the sliding hole 20. The end of the clamping rod 4 is provided with a first positioning ring 21. Two positioning rings 22, the first positioning ring 21 and the second positioning ring 22 abut to restrict the clamping rod 4 from continuing to slide out of the sliding hole 20.

[0032] It also includes a main frame 1, on which a binding strap 2 is connected, and one side of the main frame 1 is a needle removal surface 3. When the binding strap 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com