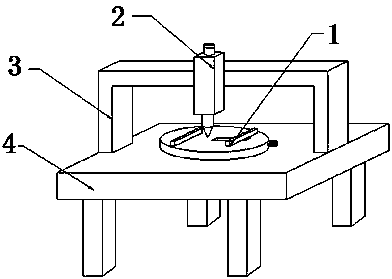

Metal engraving machining equipment

A processing equipment and metal technology, which is applied in the field of metal engraving processing equipment, can solve the problems of limited processing range, inability to adjust the processing angle, and inability to quickly clamp workpieces to be processed, so as to achieve strong practicability, good workpiece clamping effect, and adjustable angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

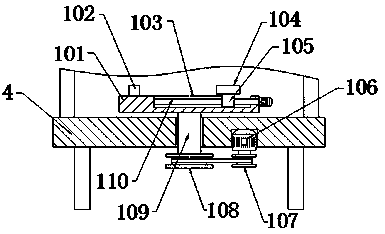

[0020] Specific implementation method: when in use, firstly, the left end face of the workpiece to be processed is closely attached to the limit block 102, and then the micro motor is operated through the control switch, and the micro motor drives the screw rod 110 to rotate in the groove 103, and the ball nut pair drives the screw rod 110. The rotary motion is converted into linear motion. The nut seat 105 drives the movable block 104 to move to the left. When the movable block 104 is closely attached to the right end surface of the workpiece to be processed, the micro drive motor 106 is stopped, and then the movable block 104 will be The workpiece to be processed is fixed on the support table 101. When the processing angle needs to be adjusted, the driving motor 106 is operated, and the driving motor 106 drives the first sprocket 107 to rotate. The first sprocket 107 drives the second sprocket 108 to rotate through the transmission chain, and the second sprocket 108 rotates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com