Mold trimming workbench and processing system

A workbench and mold technology, applied in the field of mold manufacturing, can solve the problems of difficult operation, high labor intensity, and reduced production efficiency for staff, and achieve the effect of improving work efficiency and quality, easy to rotate, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

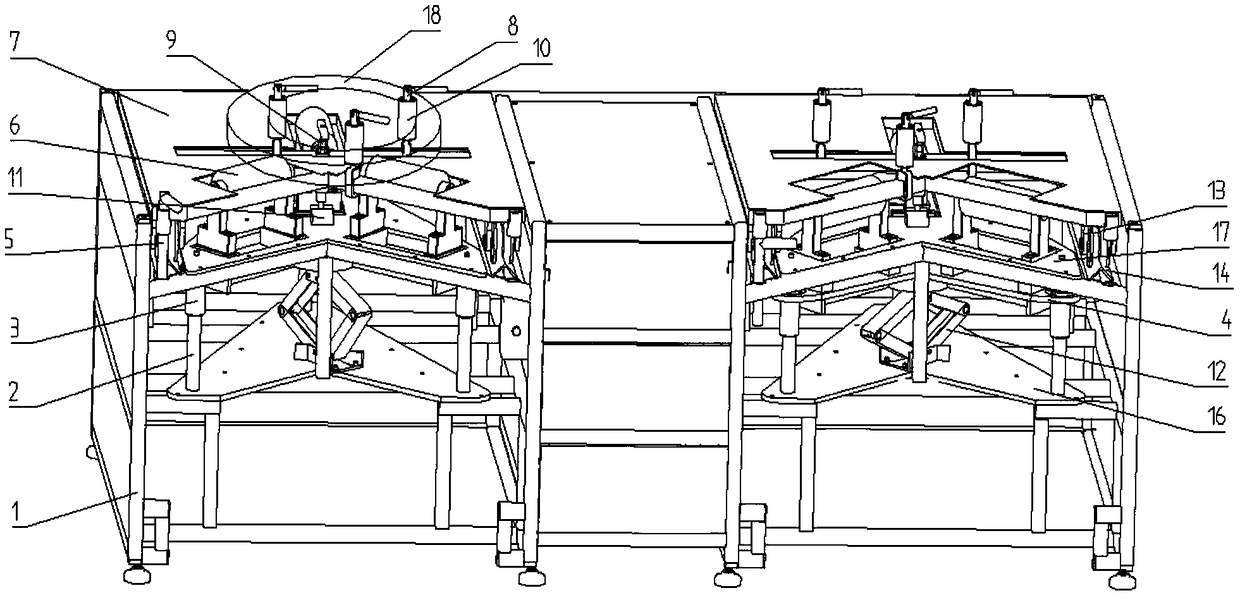

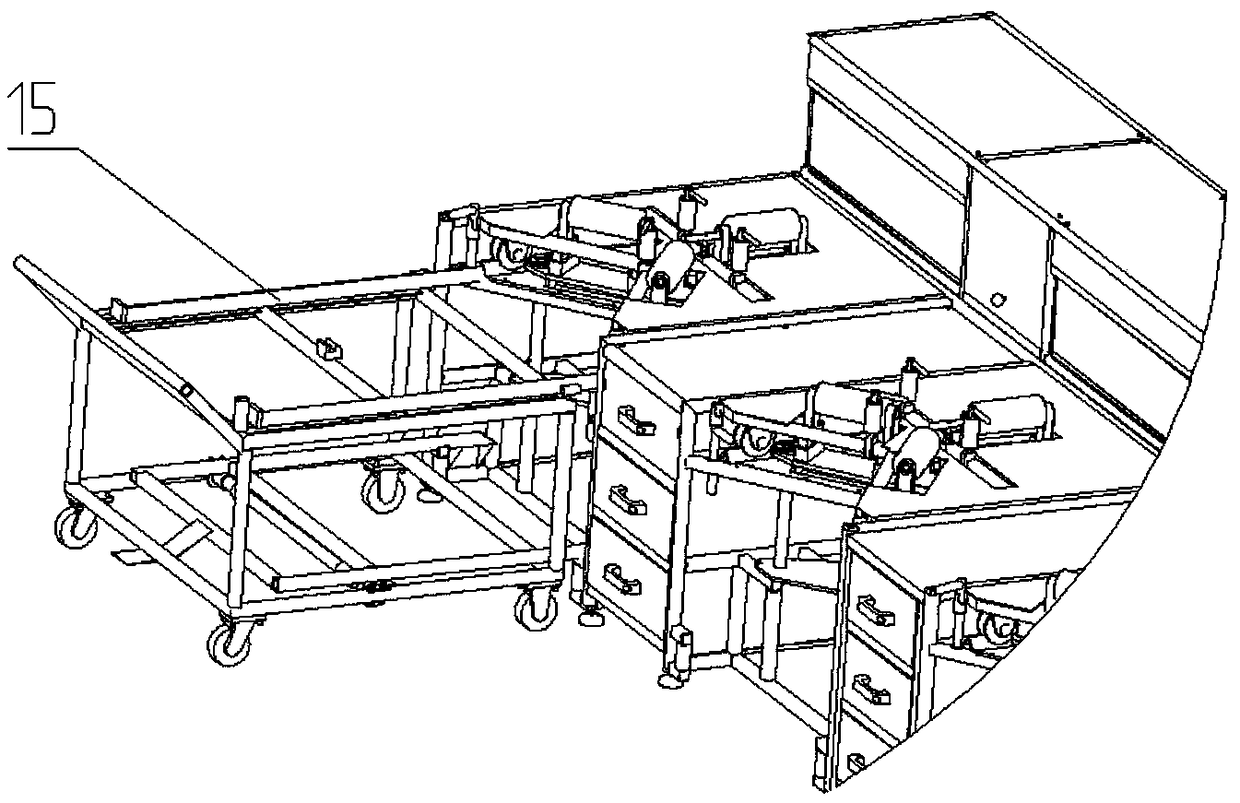

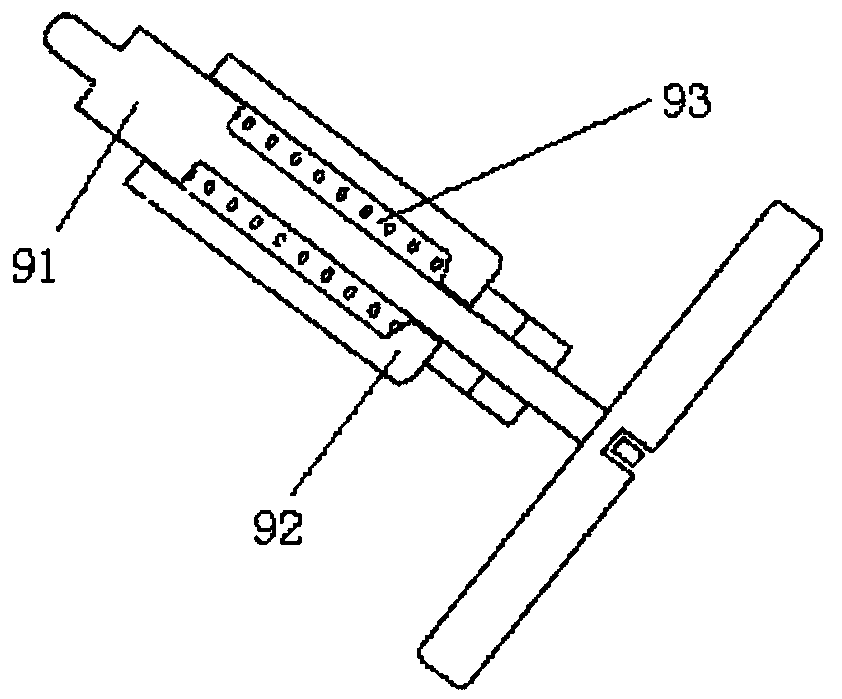

[0046] Please refer to the attached figure 1 , the present invention provides a mold trimming workbench, comprising a fixed support 1, the fixed support 1 comprises a first platform 16, the first platform 16 is provided with a second platform 17 opposite to and spaced apart from the first platform 16 and the first platform 16 A lifting bracket 4 that can move up and down between the two platforms is provided between the two platforms 17. The lifting bracket 4 includes a support plate. ) to abut against and support the supporting portion of the workpiece 18, the supporting portion can roll and fit with the workpiece 18 to realize the rotation of the workpiece 18, and the second platform 17 is also provided with a first channel for the supporting portion to be embedded (or penetrated). Slot; the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com