Robot stacking program generating method, storage medium and demonstrator

A program generation and robot technology, applied in the field of robot palletizing, can solve the problems that affect the effect of robot palletizing, complex and heavy workload, etc., and achieve the effects of improving safety, improving debugging efficiency, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

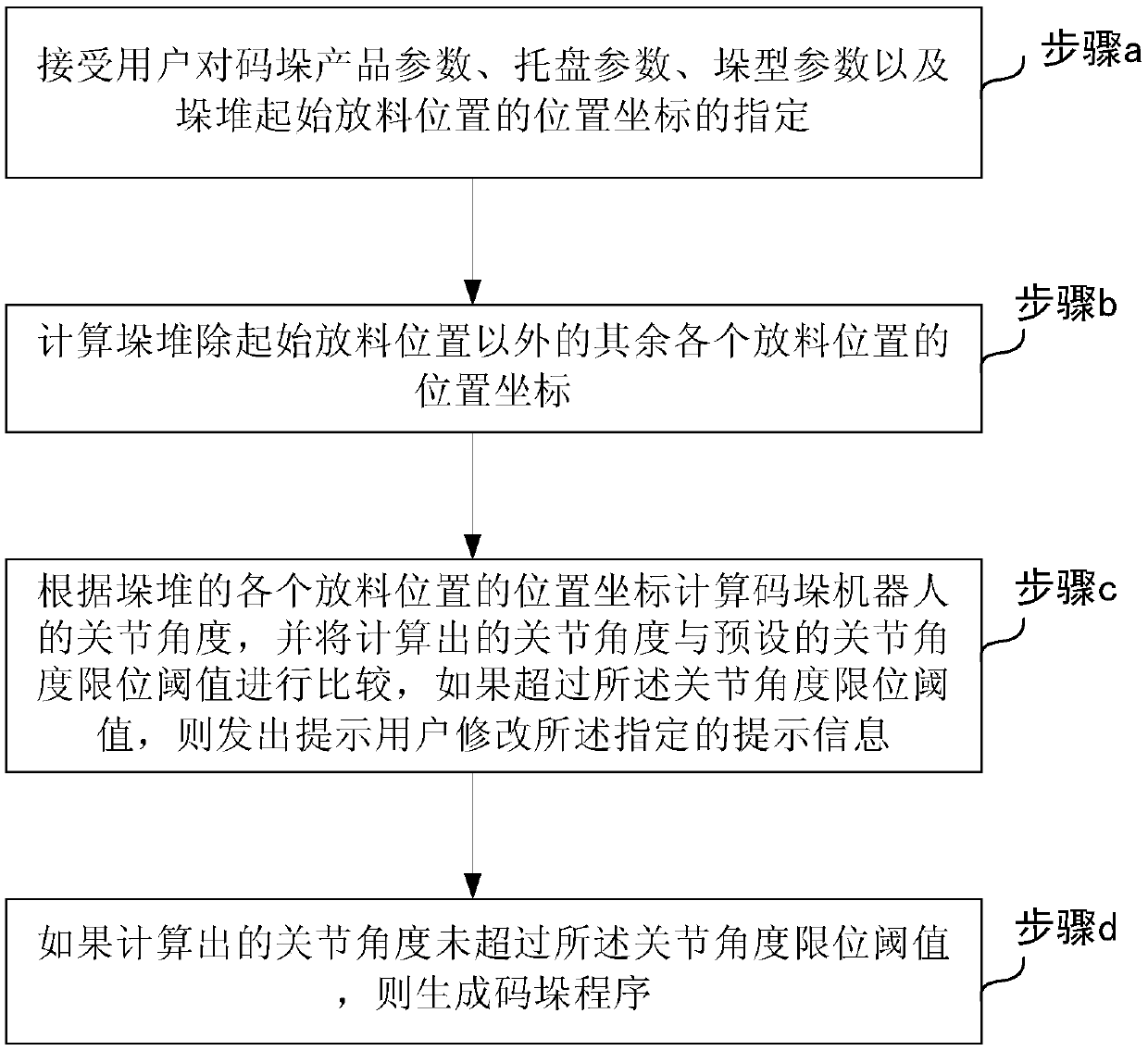

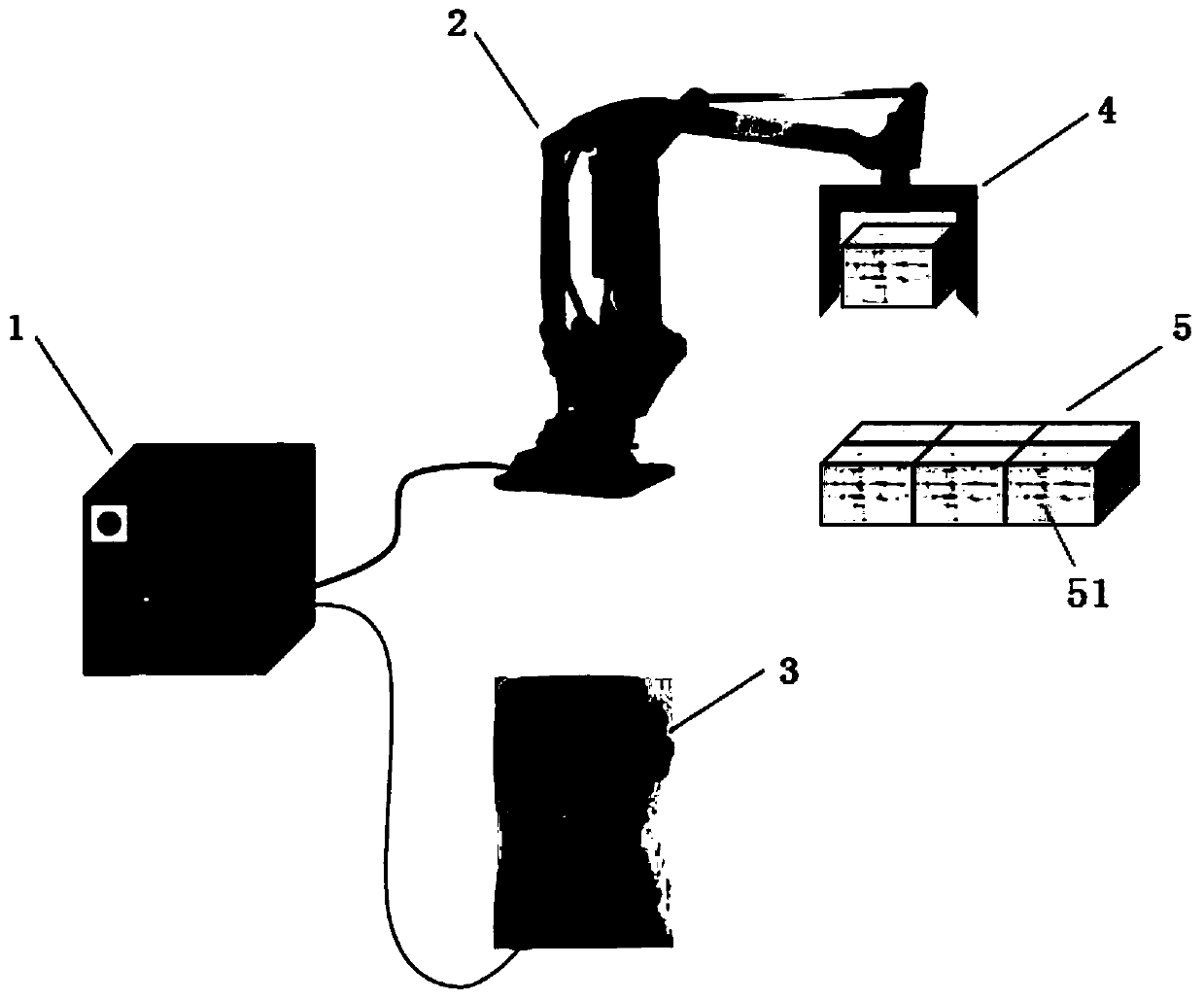

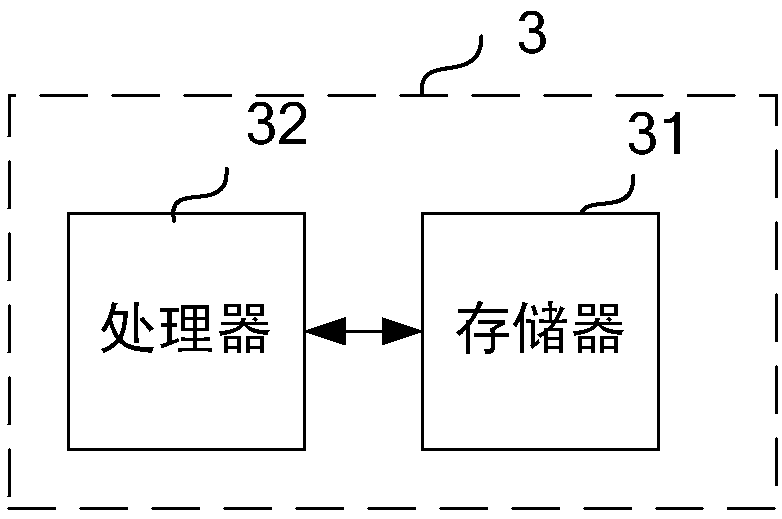

[0019] figure 1 A schematic flowchart of a method for generating a robot palletizing program according to an embodiment of the present invention is shown. see figure 1 and figure 2 , a method for generating a robot palletizing program according to an embodiment of the present invention, comprising the following steps:

[0020] Step a, accepting the user's designation of the palletizing product parameters, pallet parameters, stacking type parameters, and the position coordinates of the starting position of the stack;

[0021] Step b, calculating the position coordinates of each other discharging positions of the stack except the initial discharging position;

[0022] Step c, calculate the joint angle of the palletizing robot according to the position coordinates of each discharging position of the stack, and compare the calculated joint a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com