Heat preservation type concrete stirring device

A mixing device and concrete technology, which are applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as reducing concrete performance, affecting building quality, concrete freeze-thaw damage, etc., and achieving improved mixing performance and temperature balance. Good performance and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

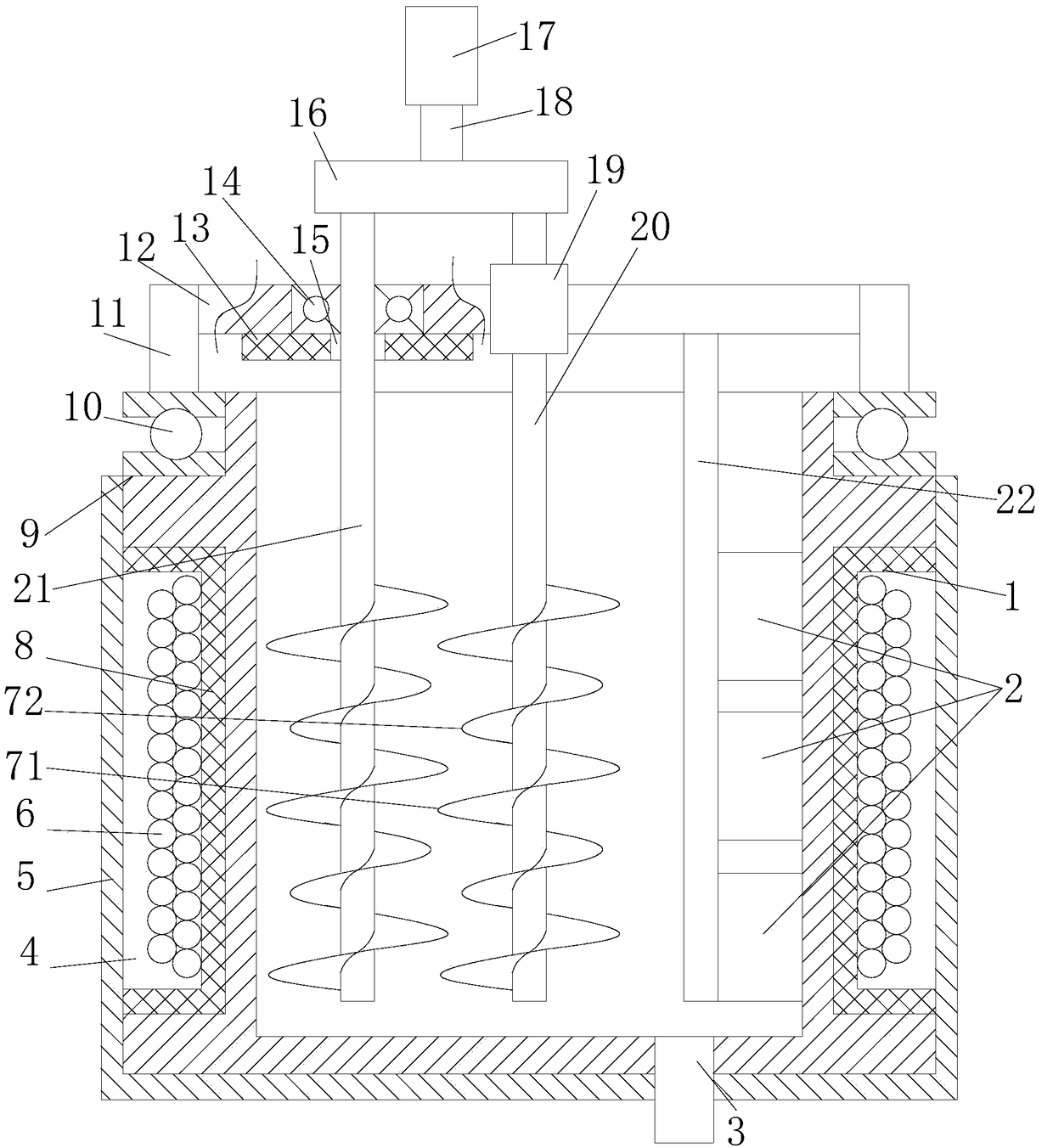

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail, as shown in the figure:

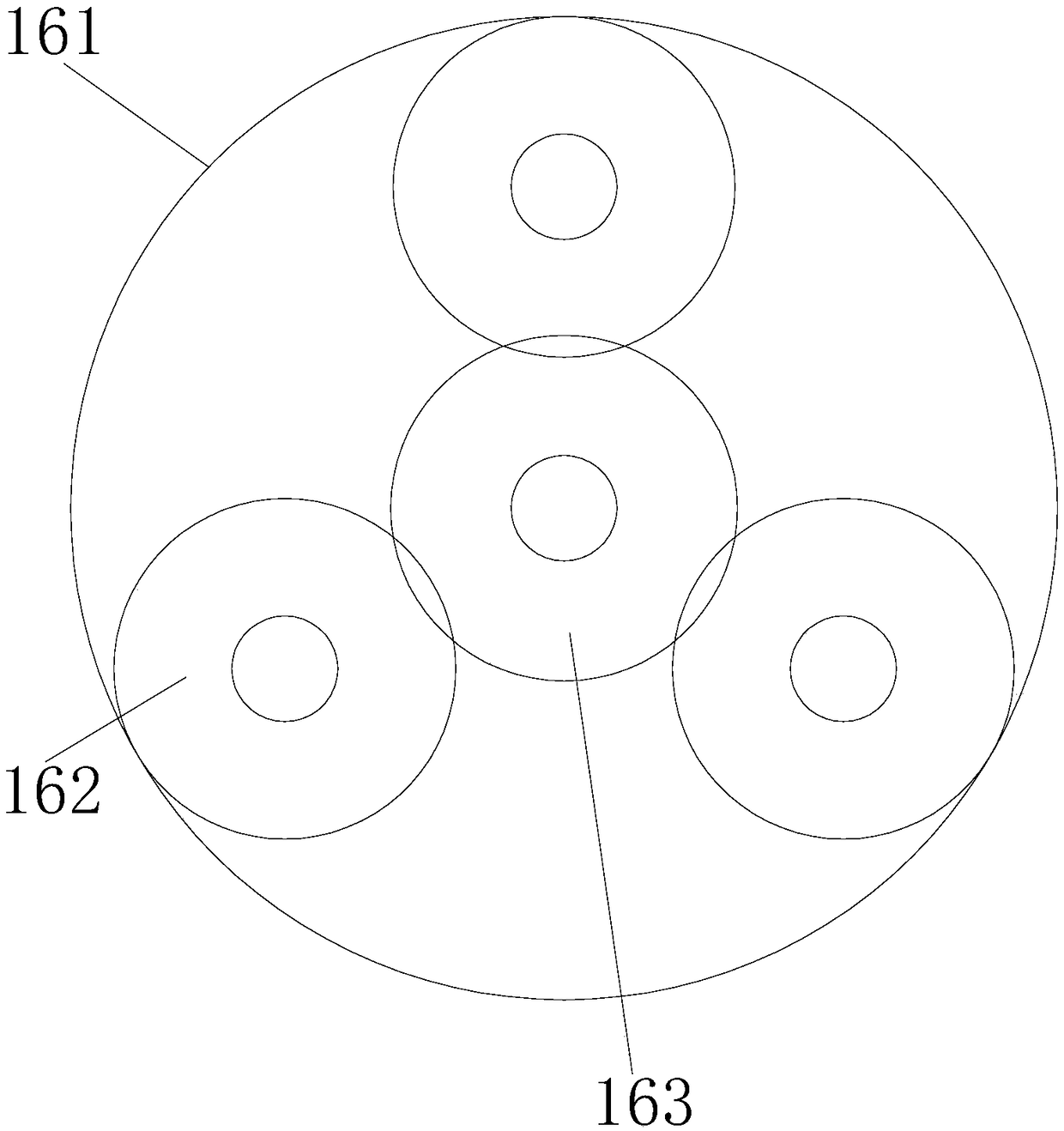

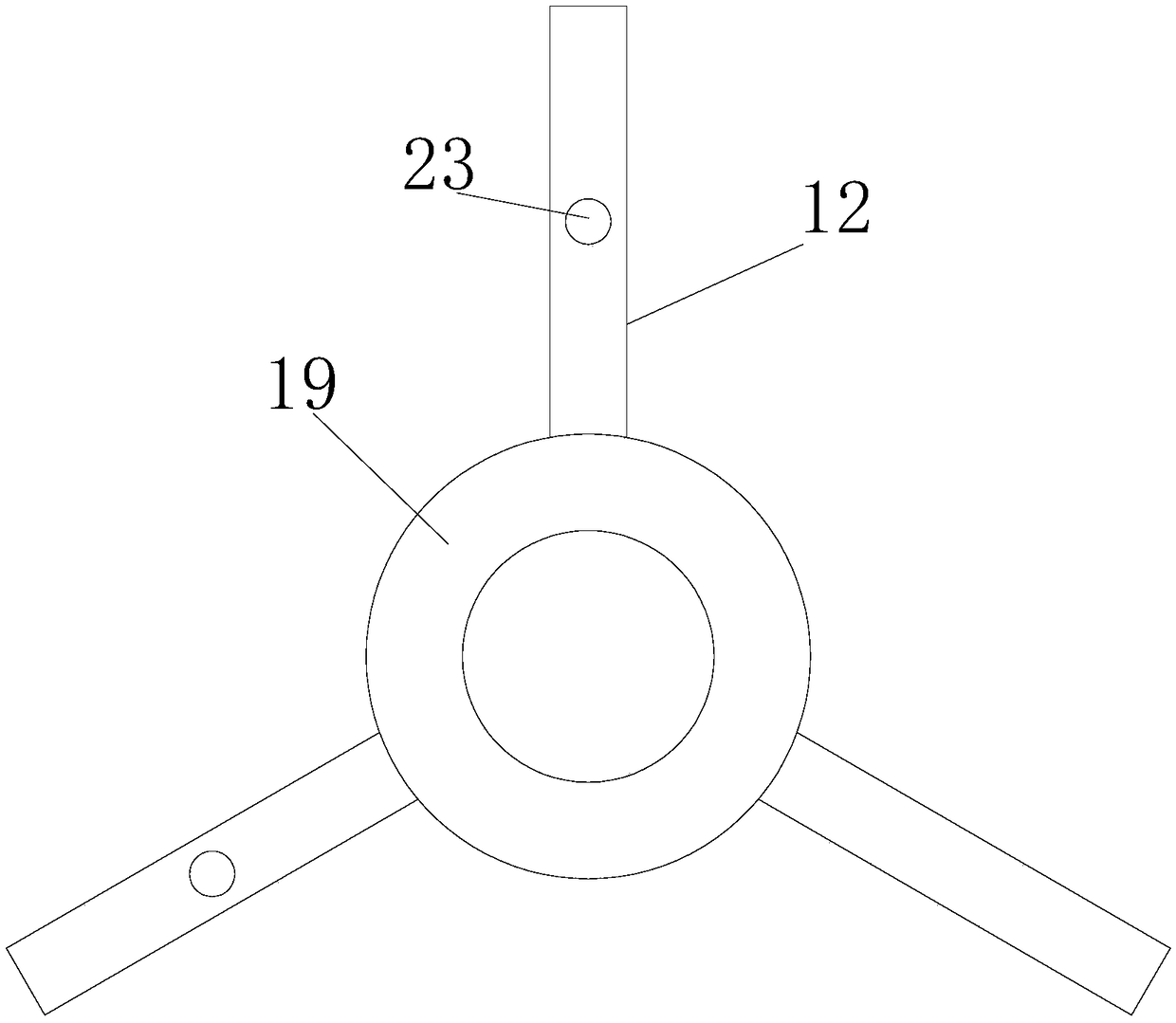

[0026] A thermal insulation concrete mixing device provided by the present invention includes a mixing drum 1, a central mixer, a first planetary mixer, a second planetary mixer and a driving mechanism;

[0027] The outer wall of the mixing drum 1 sinks along the radial direction of the mixing drum to form an annular groove 4, a heating coil 6 is arranged in the annular groove 4, and a heat conduction device is arranged between the heating coil 6 and the groove wall of the annular groove 4. Insulating layer 8, the insulating and heat insulating cylinder 5 is also covered with the mixing drum 1; wherein the thermally conductive insulating layer is made of existing thermally conductive insulating materials, such as thermally conductive silica gel, biphenyltetracarboxylic dianhydride and diphenyl ether diamine ( R type) or m-phenylenediamine (S ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com