Special automatic inflator

An automatic inflator, a special technology, applied in the direction of cardboard items, etc., can solve the problems of low work efficiency and high labor intensity of the staff, and achieve the effect of improving the inflation effect, high degree of automation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

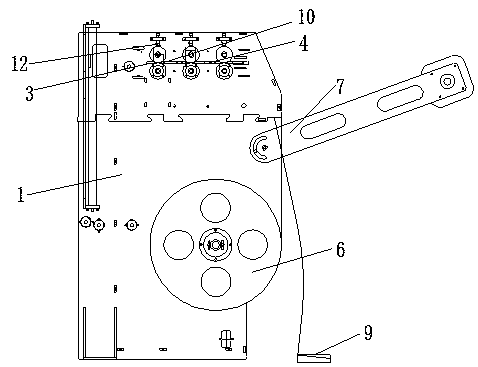

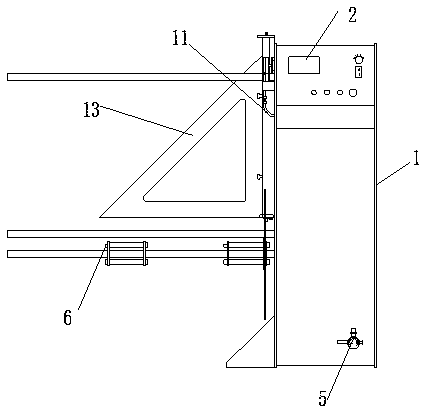

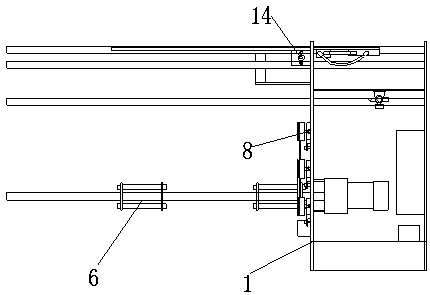

[0018] like Figure 1-3 As shown, as the first embodiment of the present invention, a special automatic inflator includes a frame 1, an operation control panel 2, an inflation tube 3, an inflation crossing cutting blade 4, an inflation pressure regulator 5, an automatic discharge Frame 6, finished product receiving rack 7 for inflatable bags, the operation control panel 2 is arranged above one side of the frame 1, and the upper part of one side of the frame 1 is provided with multiple sets of traction rollers 8 at intervals. In this embodiment , taking three pairs of traction rollers 8 as an example, the traction rollers 8 are powered by motors, and the motors are controlled by foot switches 9 to start and stop them. Each group of traction rollers 8 includes symmetrically arranged upper , two lower traction rubber rollers, the said inflation pipe 3 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com