A kind of inflation mechanism for flotation machine

A flotation machine and air intake pipe technology, applied in flotation, solid separation, etc., can solve the problems of increased manufacturing cost, difficult processing of the main shaft and bearing body, high operating cost, etc., to improve efficiency, improve aeration effect, and aeration effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

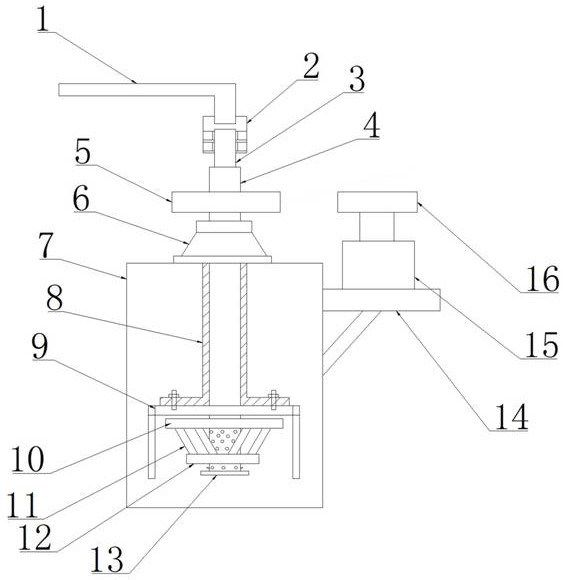

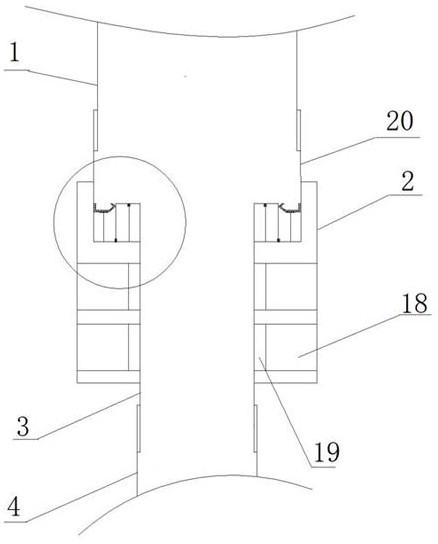

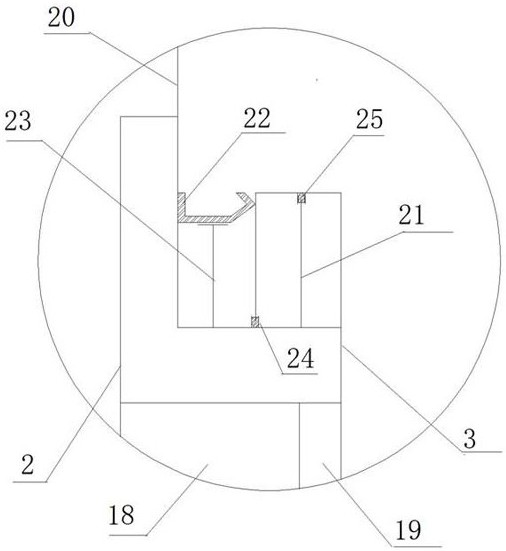

[0022] Example: such as Figure 1 to Figure 6 Shown, a kind of inflation mechanism for flotation machine, comprises casing 7, stirring mechanism, casing 7 right wall outside is provided with first support frame 14, and support frame upper end is provided with motor 15, and motor 15 output shafts are provided with active The belt pulley 16, the stirring mechanism includes a hollow shaft 4, the hollow shaft 4 is vertically arranged, the upper part of the hollow shaft 4 extends out of the box body 7, the upper end of the box body 7 is provided with a bearing body 6, and the bearing body 6 is sleeved on the hollow shaft 4, A driven pulley 5 is arranged above the bearing body 6, and the driven pulley 5 is sleeved on the hollow rotating shaft 4 through a key connection, the middle and lower part of the hollow rotating shaft 4 is arranged in the box body 7, and the lower part of the hollow rotating shaft 4 is provided with a Spoiler cover 9, spoiler cover 9 is set on the hollow rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com