Feeding mechanism achieving continuous leather material guide and preventing material from being stuck

A guiding mechanism and anti-jamming technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of different leather materials, leather materials jamming, and leather materials are not regular enough to reduce left and right swings. , to prevent material jam, to avoid the effect of left and right swing and undulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

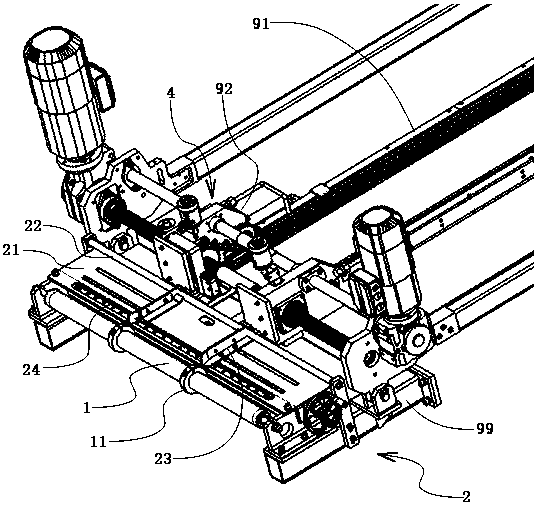

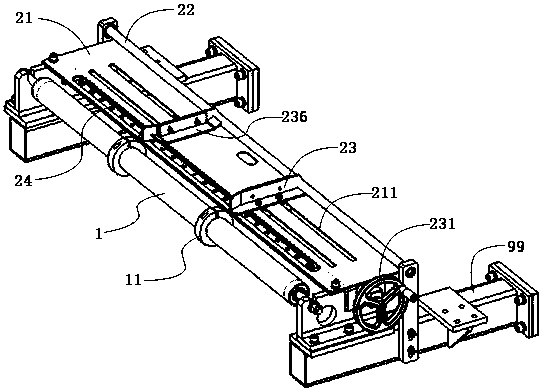

[0021] Such as figure 1 As shown, a feeding mechanism for continuous leather material guidance and anti-jamming includes a feeding guide mechanism and a platen guide mechanism 4 . The feeding guiding mechanism is arranged in front of the pressing plate guiding mechanism 4, and is used for guiding and limiting before the leather material enters the pressing plate guiding mechanism 4. The pressing plate guiding mechanism 4 is used to press the edge of leather material to the tines of the belt tine conveyor chain, so that the leather material can be dragged by the belt tine conveyor chain to move after the tines of the belt tine conveyor chain pierce the edge of leather material. There are two pressing plate guiding mechanisms 4 . The two platen guiding mechanisms 4 correspond to the toothed conveyor chains on both sides respectively. figure 1 Among them, 91 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com