A kind of drill pipe grouting method

A drill pipe and self-grouting technology, which is applied in earthwork drilling, wellbore/well parts, construction, etc., can solve the problems of high grouting cost, time-consuming and labor-intensive work, and large engineering volume, so as to reduce the engineering volume and prevent blowback , The effect of reducing the cost of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

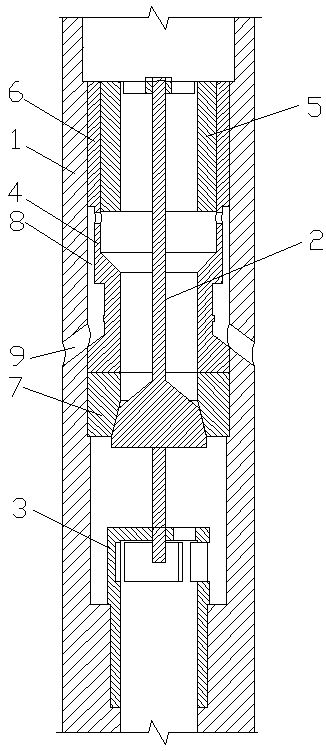

[0052] see figure 1 , a drill pipe grouting method, comprising the following steps:

[0053] a. Connect the upper end of the back pressure valve to the drill pipe, and the lower end of the back pressure valve to the drilling tool;

[0054] b. Drilling tools and back pressure valves are lowered into the well, and the mud in the well flows back into the drill pipe from bottom to top through the self-grouting channel of the back pressure valve to complete the automatic grouting of the drill pipe;

[0055] c. For positive circulation of mud, the piston 5 in the back pressure valve moves down to block the mud return slot 8 and close the self-grouting channel.

[0056] This embodiment is the most basic implementation. The upper end of the back pressure valve is connected to the drill pipe, and the lower end of the back pressure valve is connected to the drilling tool; The self-grouting channel returns the mud in the well to the drill pipe from bottom to top to complete the automat...

Embodiment 2

[0058] see figure 1 , a drill pipe grouting method, comprising the following steps:

[0059] a. Connect the upper end of the back pressure valve to the drill pipe, and the lower end of the back pressure valve to the drilling tool;

[0060] b. Drilling tools and back pressure valves are lowered into the well, and the mud in the well flows back into the drill pipe from bottom to top through the self-grouting channel of the back pressure valve to complete the automatic grouting of the drill pipe;

[0061] c. For positive circulation of mud, the piston 5 in the back pressure valve moves down to block the mud return slot 8 and close the self-grouting channel.

[0062] In the step a, the back pressure valve is a self-grouting back pressure valve, including the valve body 1, the valve core 2, the support seat 3 and the valve seat 4 arranged in the valve body 1, and the support seat 3 is located below the valve seat 4 , the valve body 1 is provided with a piston 5, the piston 5 is s...

Embodiment 3

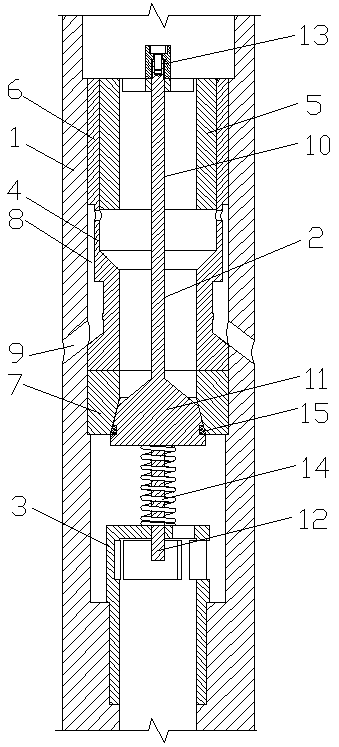

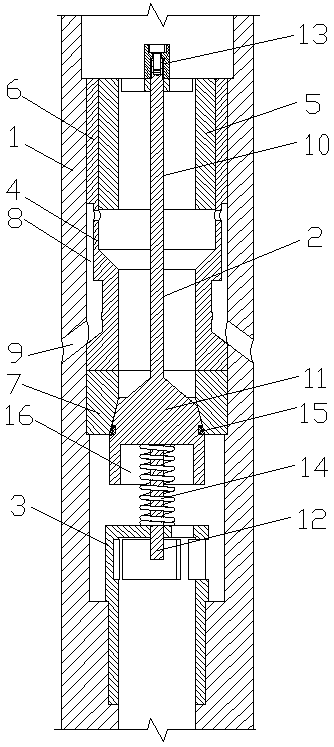

[0066] see figure 2 , a drill pipe grouting method, comprising the following steps:

[0067] a. Connect the upper end of the back pressure valve to the drill pipe, and the lower end of the back pressure valve to the drilling tool;

[0068] b. Drilling tools and back pressure valves are lowered into the well, and the mud in the well flows back into the drill pipe from bottom to top through the self-grouting channel of the back pressure valve to complete the automatic grouting of the drill pipe;

[0069] c. For positive circulation of mud, the piston 5 in the back pressure valve moves down to block the mud return slot 8 and close the self-grouting channel.

[0070]In the step a, the back pressure valve is a self-grouting back pressure valve, including the valve body 1, the valve core 2, the support seat 3 and the valve seat 4 arranged in the valve body 1, and the support seat 3 is located below the valve seat 4 , the valve body 1 is provided with a piston 5, the piston 5 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com