A graphitic carbon nitride modified emulsified pitch and its photocatalytic application

A technology of graphite phase carbon nitride and emulsified pitch, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of low cost, good compatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Graphite carbon nitride (g-C 3 N 4 ) Preparation of photocatalyst

[0023] (1) Weigh 10g of urea, cyanamide, dicyandiamide, and melamine respectively, and place them in four 50ml porcelain crucibles with lids. At the same time, place it in a muffle furnace, set the heating rate at 10°C / min, raise it to 550°C, and keep it warm for 2h.

[0024] (2) Grinding the collected product when the furnace is cooled to room temperature to obtain graphite phase carbon nitride with a particle size of 300nm-500nm, which is set aside.

Embodiment 2

[0026] Preparation of graphite phase carbon nitride modified emulsified pitch

[0027] In parts by weight (Kg): 100 parts of emulsified pitch, 9 parts of graphite phase carbon nitride, and 6 parts of water-based polymer (wherein the water-based polymer adopts polyacrylic acid emulsion).

[0028] (a) by the above-mentioned parts by weight, graphite phase carbon nitride is uniformly dispersed in the aqueous polymer solution under the action of ultrasonic waves;

[0029] (b) stirring and mixing the graphite-phase carbon nitride / water-based polymer obtained in step (a) and the emulsified pitch through a high-speed shearing machine to obtain the graphite-phase carbon nitride-modified emulsified pitch.

Embodiment 3

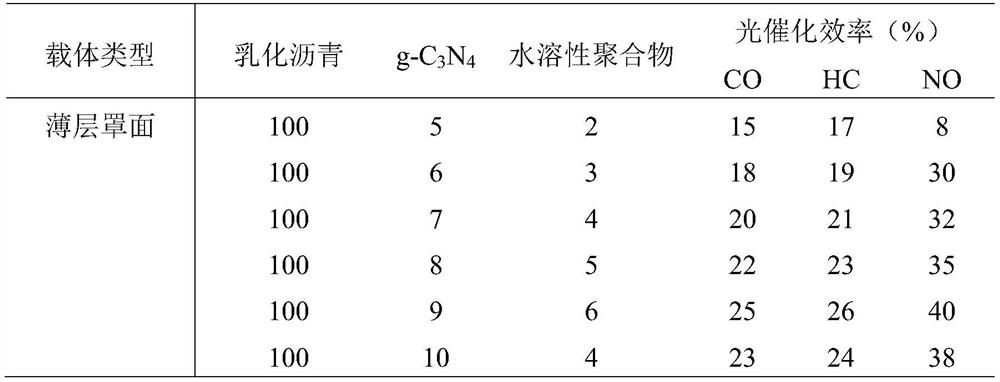

[0031] With g-C prepared by the method of embodiment 1 3 N 4 It is used as a raw material, mixed with emulsified asphalt and water-soluble polymer, and stirred and mixed by a high-speed shearing machine to obtain modified emulsified asphalt. See Table 1 for the specific raw material ratio and the automobile exhaust degradation effect of the thin-layer overlay prepared by emulsified asphalt.

[0032] Table 1: Photocatalytic efficiency of modified emulsified asphalt with different ratios

[0033]

[0034] The modified emulsified asphalt provided by the invention can effectively utilize visible light, has good photocatalytic effect, can effectively degrade nitrogen oxides and hydrocarbons in tail gas, and has a simple and convenient preparation method. The prepared modified emulsified asphalt can be used as a binder for thin-layer overlays, micro-surfacing, and mist-sealed layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com