Steam-generating pressure reactor

A technology of autoclave and steam, which is used in pressure vessel components, pressure vessels used in chemical processes, waste heat treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

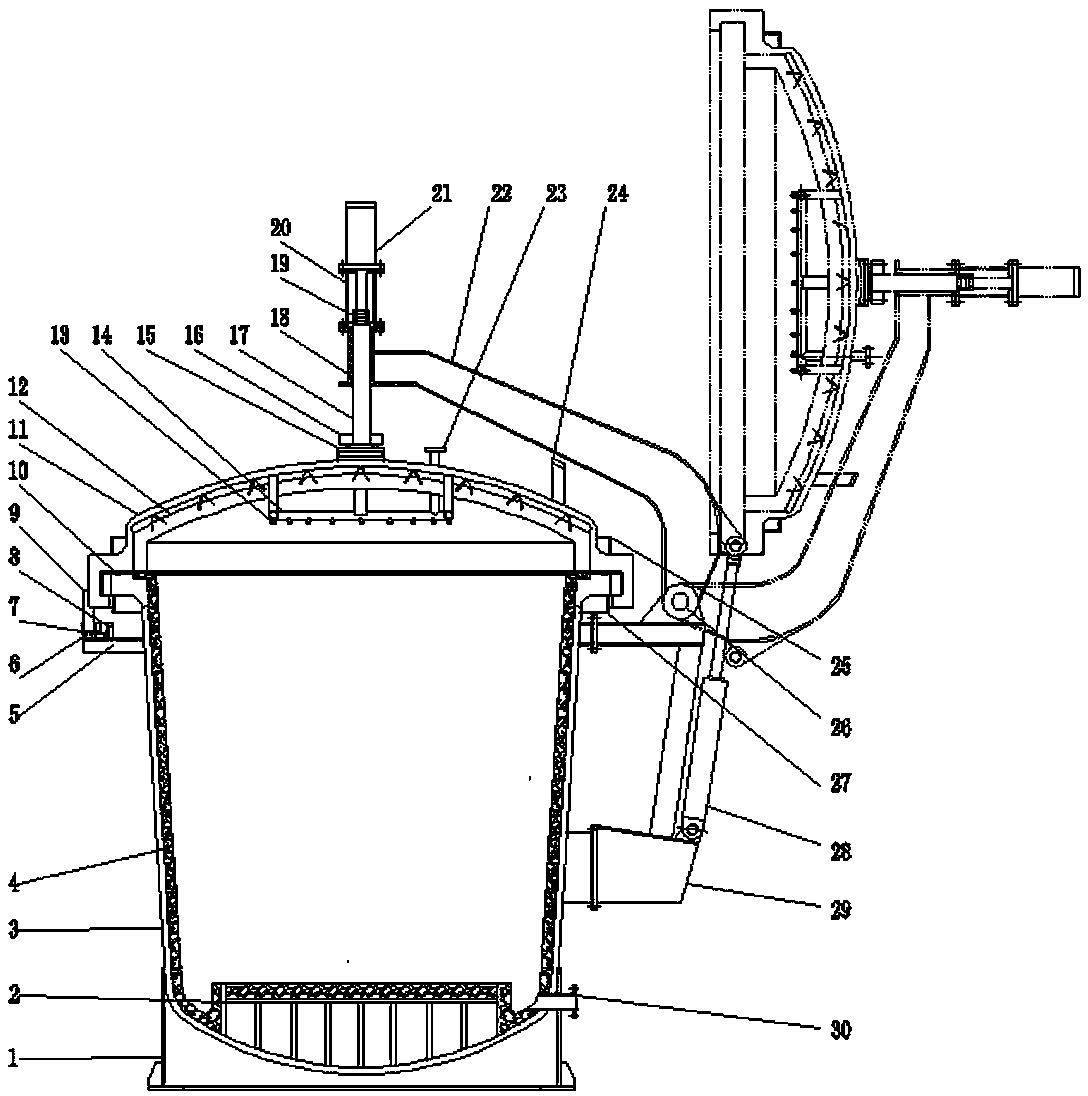

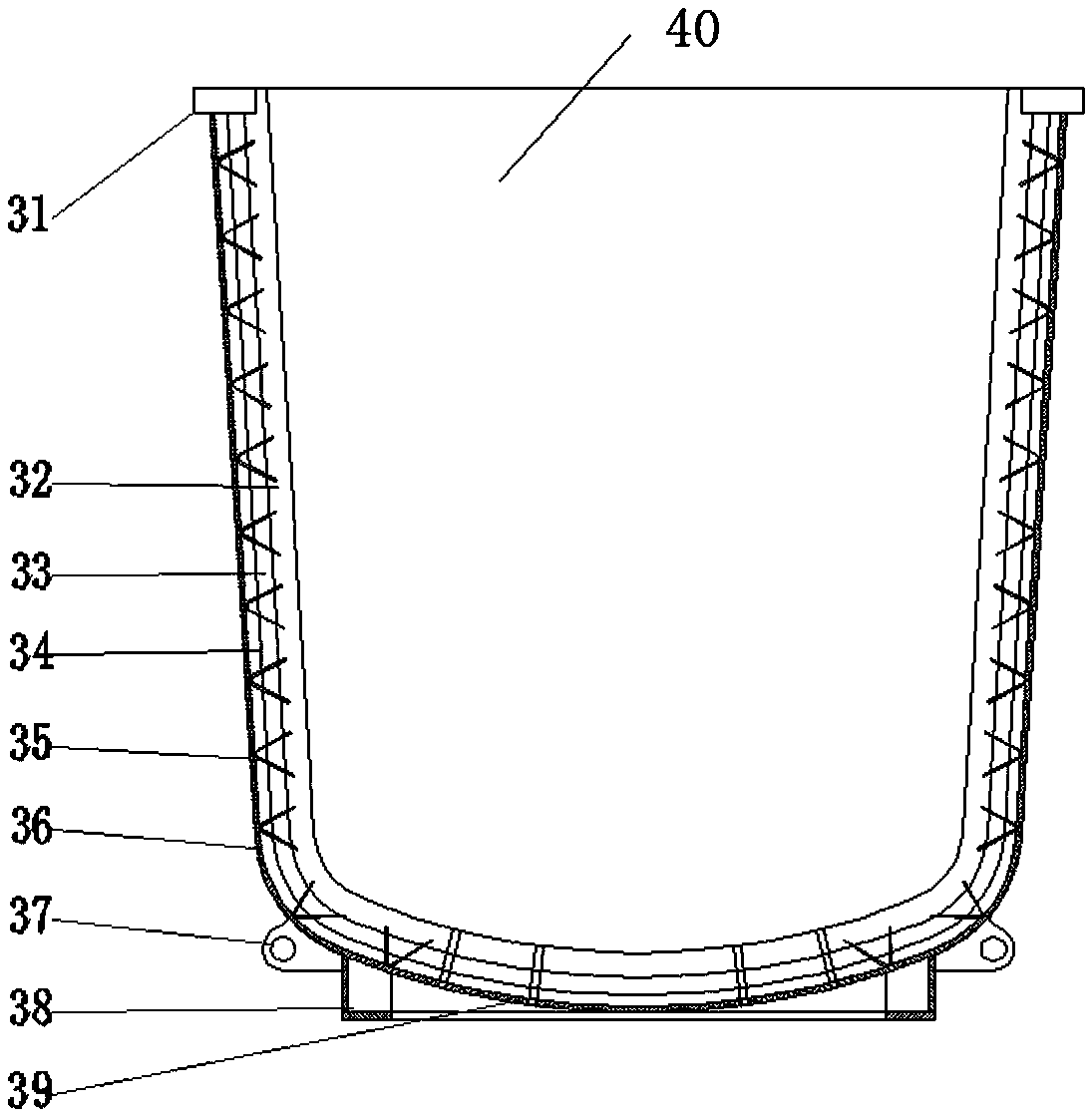

[0023] Such as figure 1 As shown, a steam producing pressure kettle has a structure including a kettle body 3, an insulation layer 4 inside the kettle body, a kettle lid 11, a kettle lid heat insulation layer 12, a spray system, and a locking device.

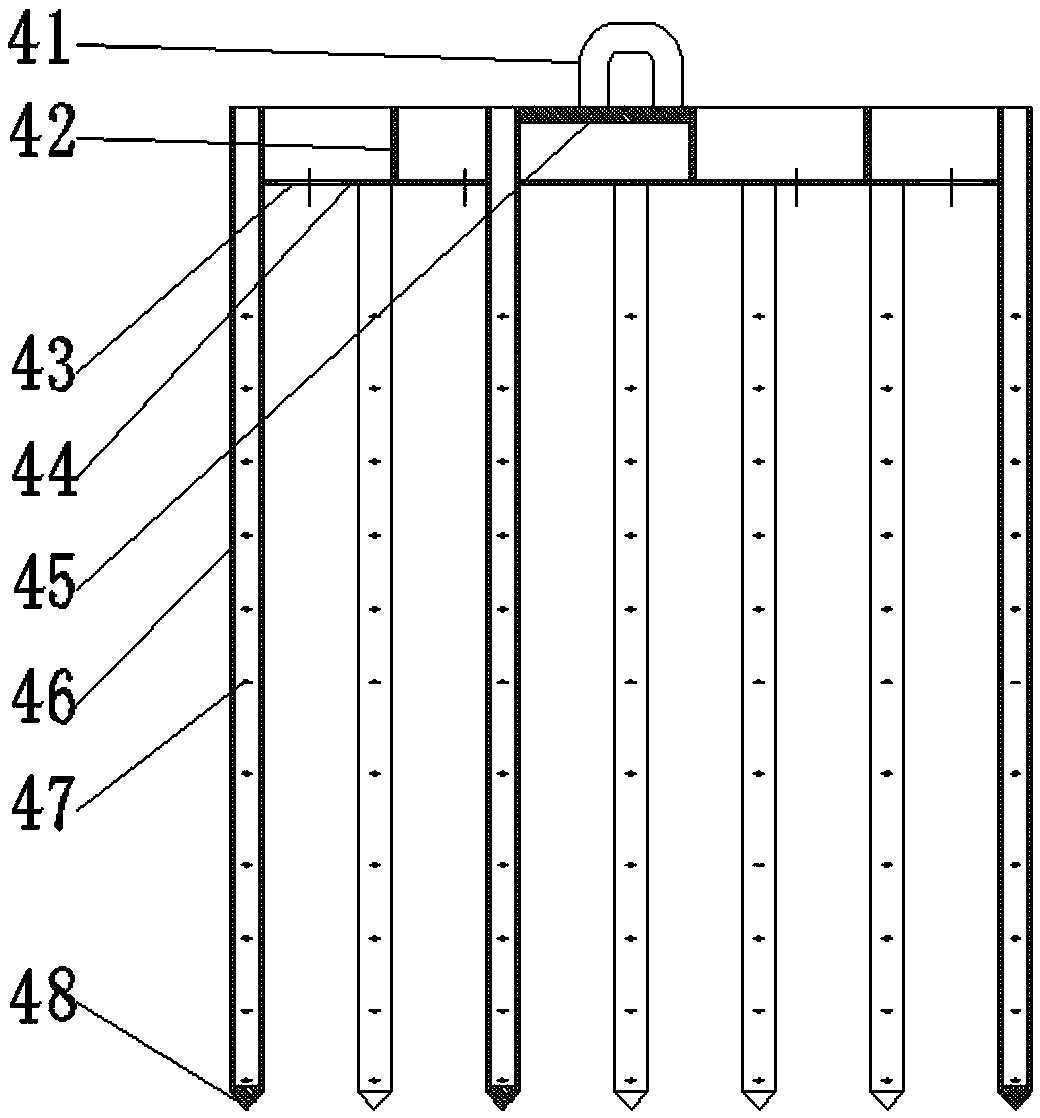

[0024] The inner side of the kettle body 3 is provided with a thermal insulation layer 4 in the kettle body, the inner side of the kettle cover 11 is provided with a thermal insulation layer 12 of the kettle cover, a locking device is provided at the joint between the kettle body 3 and the kettle cover 11, and a spray nozzle is provided under the kettle cover 11. The shower system is provided with a steam output interface 51 on the top of the kettle body 3 (see Image 6 ), a safety valve interface 52, and a drainage interface 30 is provided at the bottom of the kettle body 3.

[0025] The spray system includes a water inlet pipe 23 passing through the kettle cover 11, the lower end of the water inlet pipe 23 is connected to the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap