Combination cutter set of shield tunneling machine

A technology of shield machine and combined knife, which is applied in mining equipment, earthwork drilling, tunnels, etc. It can solve problems such as loss of function, limited lubrication and impact, and difficulty in shield construction, so as to increase the use time and increase excavation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

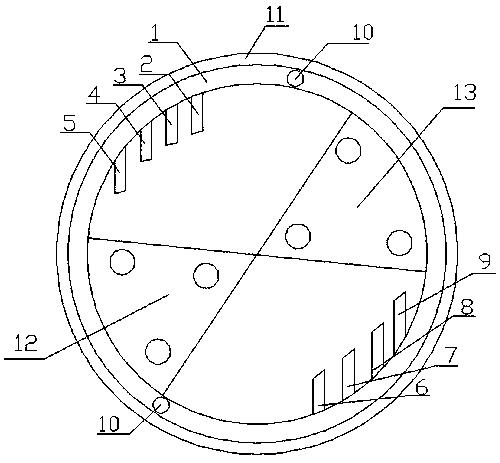

[0025] A combination knife set of a shield machine, characterized in that it includes: a main body of a mud-proof device 1, a first flushing pipe 2, a second flushing pipe 3, a third flushing pipe 4, a fourth flushing pipe 5, a fifth flushing pipe 6, The sixth scouring pipe 7, the seventh scouring pipe 8, the eighth scouring pipe 9 and the installation hole 10 of the anti-mud device. One side of the main body 1 is provided with a first flushing pipe 2, a second flushing pipe 3, a third flushing pipe 4 and a fourth flushing pipe 5, and the other side of the main body 1 of the anti-mud device is provided with a fifth flushing pipe 6, The sixth scouring pipe 7, the seventh scouring pipe 8 and the eighth scouring pipe 9, the main body of the anti-mud device is provided with a plurality of installation holes 10 for the anti-mud device, and the main body of the anti-mud device 1 is arranged on the cutter head of the shield machine 11 , the first hob unit 12 of the shield machine and...

Embodiment 2

[0031] A combination knife set of a shield machine, characterized in that it includes: a main body of a mud-proof device 1, a first flushing pipe 2, a second flushing pipe 3, a third flushing pipe 4, a fourth flushing pipe 5, a fifth flushing pipe 6, The sixth scouring pipe 7, the seventh scouring pipe 8, the eighth scouring pipe 9 and the installation hole 10 of the anti-mud device. One side of the main body 1 is provided with a first flushing pipe 2, a second flushing pipe 3, a third flushing pipe 4 and a fourth flushing pipe 5, and the other side of the main body 1 of the anti-mud device is provided with a fifth flushing pipe 6, The sixth scouring pipe 7, the seventh scouring pipe 8 and the eighth scouring pipe 9, the main body of the anti-mud device is provided with a plurality of installation holes 10 for the anti-mud device, and the main body of the anti-mud device 1 is arranged on the cutter head of the shield machine 11 , the first hob unit 12 of the shield machine and...

Embodiment 3

[0033] A combination knife set of a shield machine, characterized in that it includes: a main body of a mud-proof device 1, a first flushing pipe 2, a second flushing pipe 3, a third flushing pipe 4, a fourth flushing pipe 5, a fifth flushing pipe 6, The sixth scouring pipe 7, the seventh scouring pipe 8, the eighth scouring pipe 9 and the installation hole 10 of the anti-mud device. One side of the main body 1 is provided with a first flushing pipe 2, a second flushing pipe 3, a third flushing pipe 4 and a fourth flushing pipe 5, and the other side of the main body 1 of the anti-mud device is provided with a fifth flushing pipe 6, The sixth scouring pipe 7, the seventh scouring pipe 8 and the eighth scouring pipe 9, the main body of the anti-mud device is provided with a plurality of installation holes 10 for the anti-mud device, and the main body of the anti-mud device 1 is arranged on the cutter head of the shield machine 11 , the first hob unit 12 of the shield machine and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com