Novel vehicle air conditioner evaporator

A technology for automotive air conditioners and evaporators, applied in evaporator/condenser, heat exchange equipment, damage protection, etc., can solve the problem of reducing the heat exchange effect between air and louver fins, unable to completely eliminate the effect of condensed water, affecting air circulation, etc. problem, to achieve the effect of ingenious and practical mechanism design, good discharge, and enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

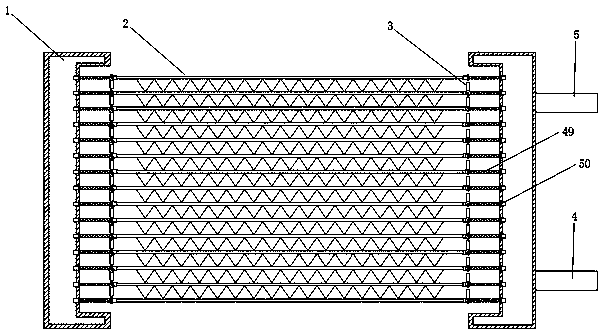

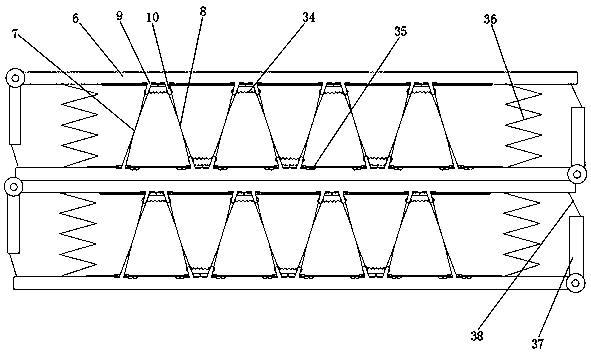

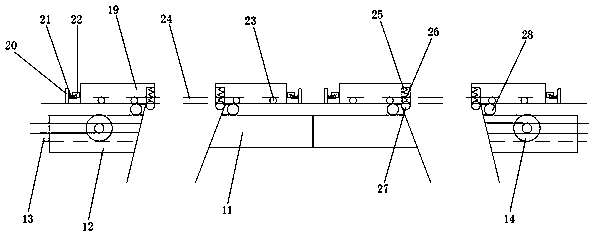

[0030] As shown in the drawings of the description, a new type of automobile air-conditioning evaporator includes a header system 1, an evaporation heat exchange device 2, a fin movable device 3, a condensed water treatment system 51 and a control system; the header system 1 Placed vertically, the side is provided with a liquid inlet pipe 4 and a liquid outlet pipe 5; the evaporation heat exchange device 2 includes flat pipes 6, louver fins I7, louver fins II8, ports 9, auxiliary heat exchange chambers 10, wipers Block 11, movable connection block 12, track I13, movable buckle 14, port movable cover 19, limit buckle I21, limit buckle II22, push-pull spring cavity 25, push-pull spring 26, dial ball 27, fulcrum buckle 28 and Drainage groove 35; the flat tube 6 is placed horizontally in the middle of the header system 1; the louver fin I7 is inclined to the right, and the louver fin II8 is inclined to the left, forming a "V"-shaped arrangement in the adjacent between the two flat...

Embodiment 2

[0038] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1, the difference is that the evaporation heat exchange device 2 also includes a limiting plate 20; the limiting plate 20 is arranged behind the port movable cover 19; The buckle I 21 is arranged on the limiting plate 20 and faces the movable cover 19 of the port. The function of the limit plate 20 is to support the limit buckle I21 and play the role of limit.

Embodiment 3

[0040] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1, the difference is that the evaporation heat exchange device 2 also includes a roller 23 and a track II 24; the movable cover 19 and the track II 24 are arranged in the flat tube 6; The port movable cover 19 is inserted into the track II 24 through the roller 23 arranged at the bottom. The roller drives the port movable cover to move on the track II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com