Inflation box fixed grate bed of grate cooler

A grate cooler and air-filled box technology, applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of fan return air, clinker ineffective cooling, material layer blowing through, etc., to improve quality and grindability, improve heat recovery efficiency, and reduce system coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

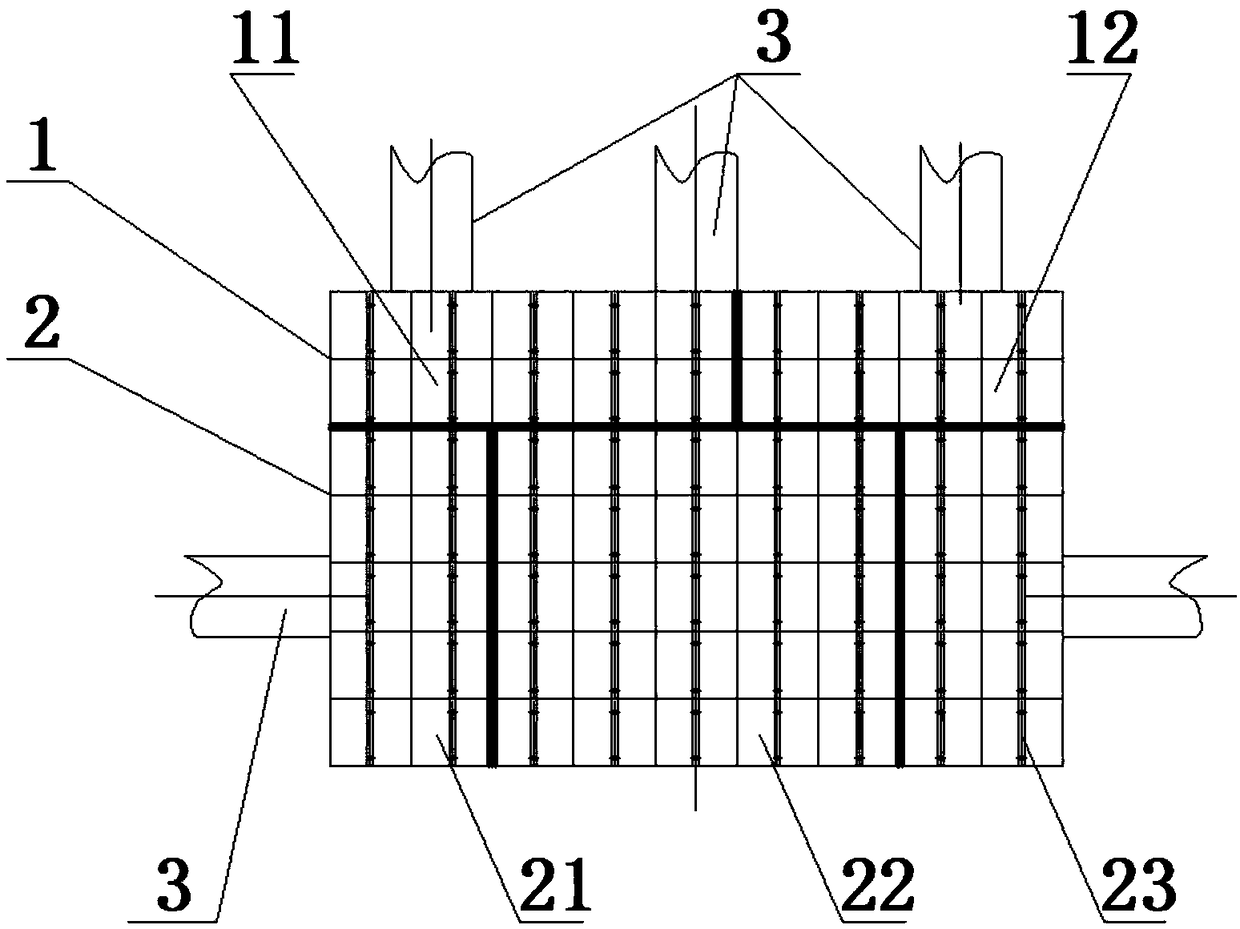

[0033] Such as Figure 1~4 Shown: a cement clinker grate cooler partition combined air box fixed grate bed,

[0034] Including a combined air box, the combined air box is composed of two combined modules arranged longitudinally, the combined module includes an air chamber and a grate plate arranged on the air chamber, and the air chambers of each combined module are equally divided It is several partitions connected with fans,

[0035] The air chamber of the end combined module 1 is divided into 2 partitions, which are the first left partition 12 and the first right partition 11 arranged horizontally; the air chamber of the non-end combined module 2 is divided into 3 partitions, which are arranged horizontally The second left partition 23, the second middle partition 22 and the third right partition are set.

[0036] The partitions are not connected, and each partition is equipped with a separate fan for air supply, and the air pressure and air volume in each partition are i...

Embodiment 2

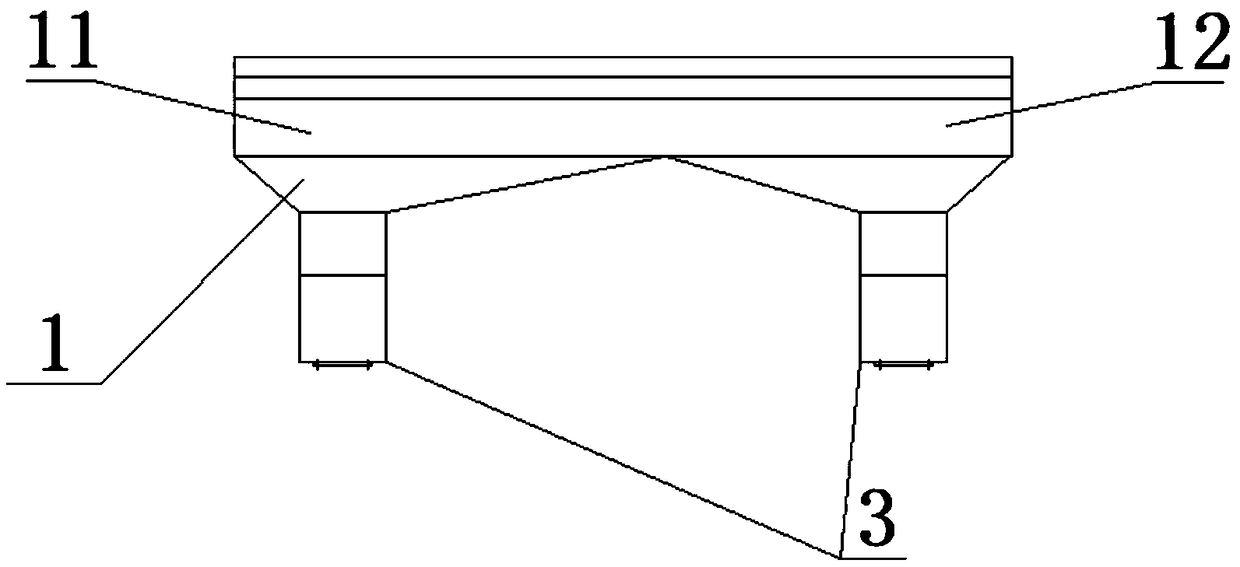

[0040] Such as Figure 5~6 Shown: the difference between this embodiment and embodiment 1 is: a fixed grate bed of a cement clinker grate cooler partition combined inflatable box, including a combined inflatable box, the combined inflatable box is composed of two combined The combined module consists of an air chamber and a grate plate arranged on the air chamber, and the air chamber of each combined module is divided into several partitions connected with the fan, and the end combined module 1 air chamber is divided into It is two partitions, and it is the first left partition 12 and the first right partition 11 arranged horizontally; the non-end combined module 2 air chamber is divided into three partitions, and it is the second left partition 23 and the first Second middle partition 22 and third right partition.

[0041] The first left partition 12 and the first right partition 11 of the end combined module 1 communicate with the second left partition 23 and the second rig...

Embodiment 3

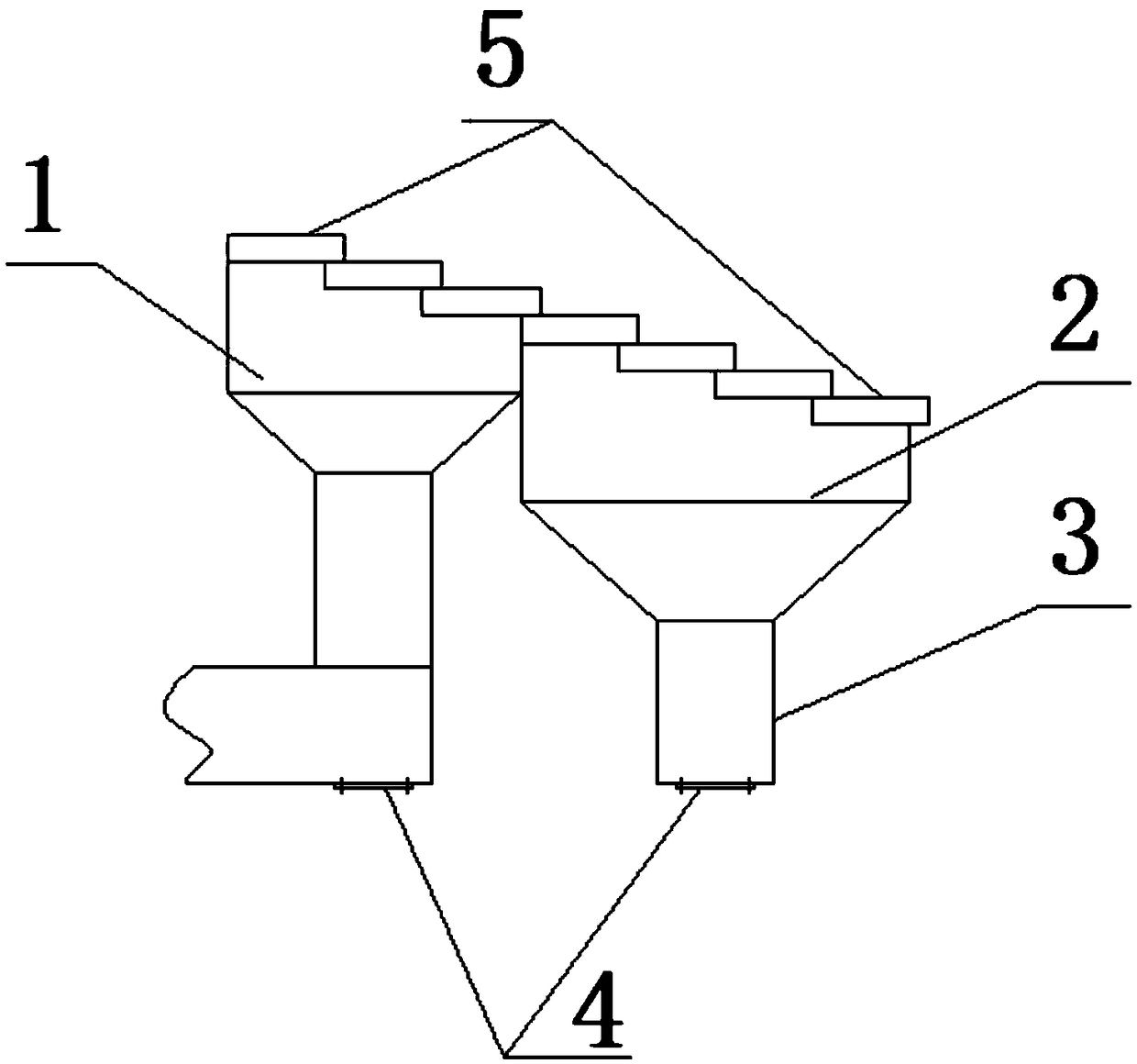

[0044] The difference between this embodiment and embodiment 1 or 2 is:

[0045] According to the requirements of wind pressure and air volume at different positions in each zone, divide the zone into several vertical and / or vertically arranged sub-zones. Thereby, the ability to adjust the air pressure and air volume of each partition can be improved.

[0046] At the same time, according to the number of sub-divisions of an inflatable sub-division and the air volume and wind pressure requirements of different sub-divisions, one or several air inlet pipes 3 are provided for an inflatable subdivision. All the sub-districts that make up the sub-division are set to be connected to each other; and when an air inlet pipe 3 is set for several sub-divisions, these sub-divisions are set to be connected to each other; For tube 3, set the sub-partitions to be mutually closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com