High-frequency partial discharge measurement position marking tool

A partial discharge, measuring position technology, applied in the direction of measuring devices, electrical measuring instrument parts, measuring electricity, etc., can solve the problem of not clearly recording the last measurement position, inability to reach, etc., to achieve a fixed spray shape, beautiful, and reduced. Small height error, simple and efficient spraying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

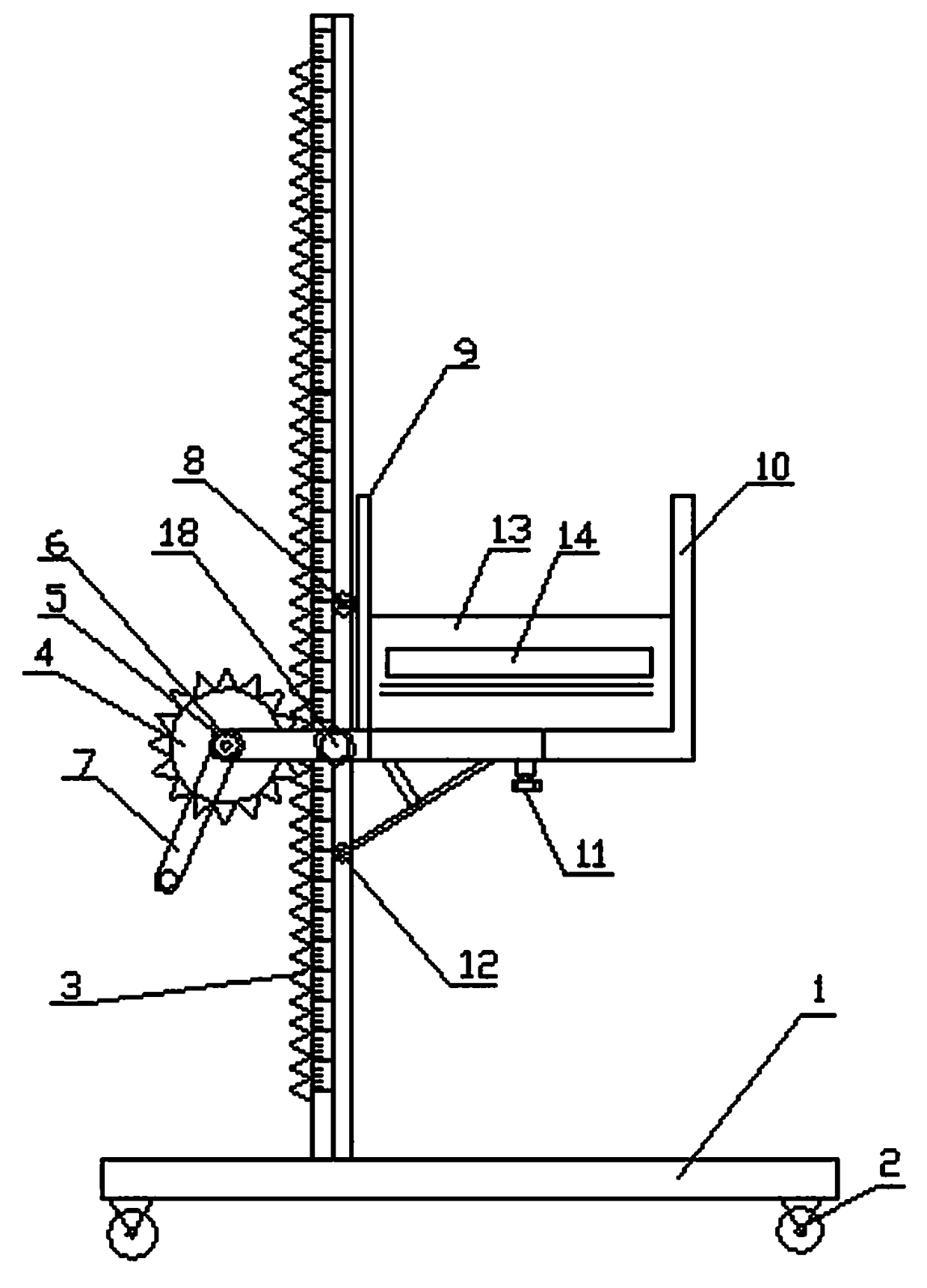

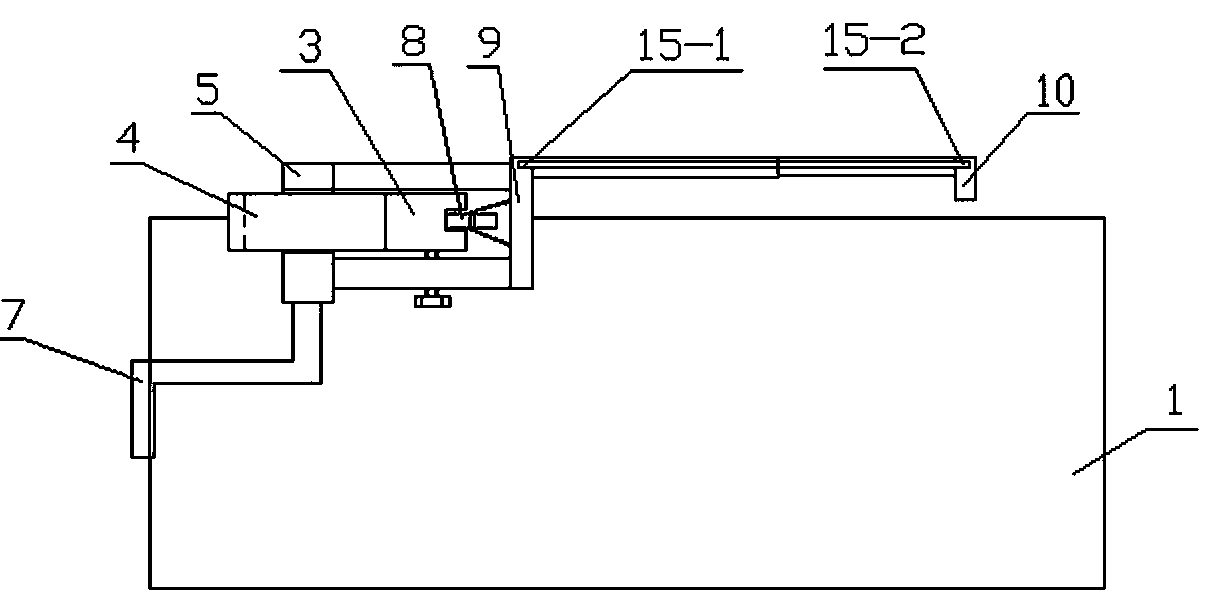

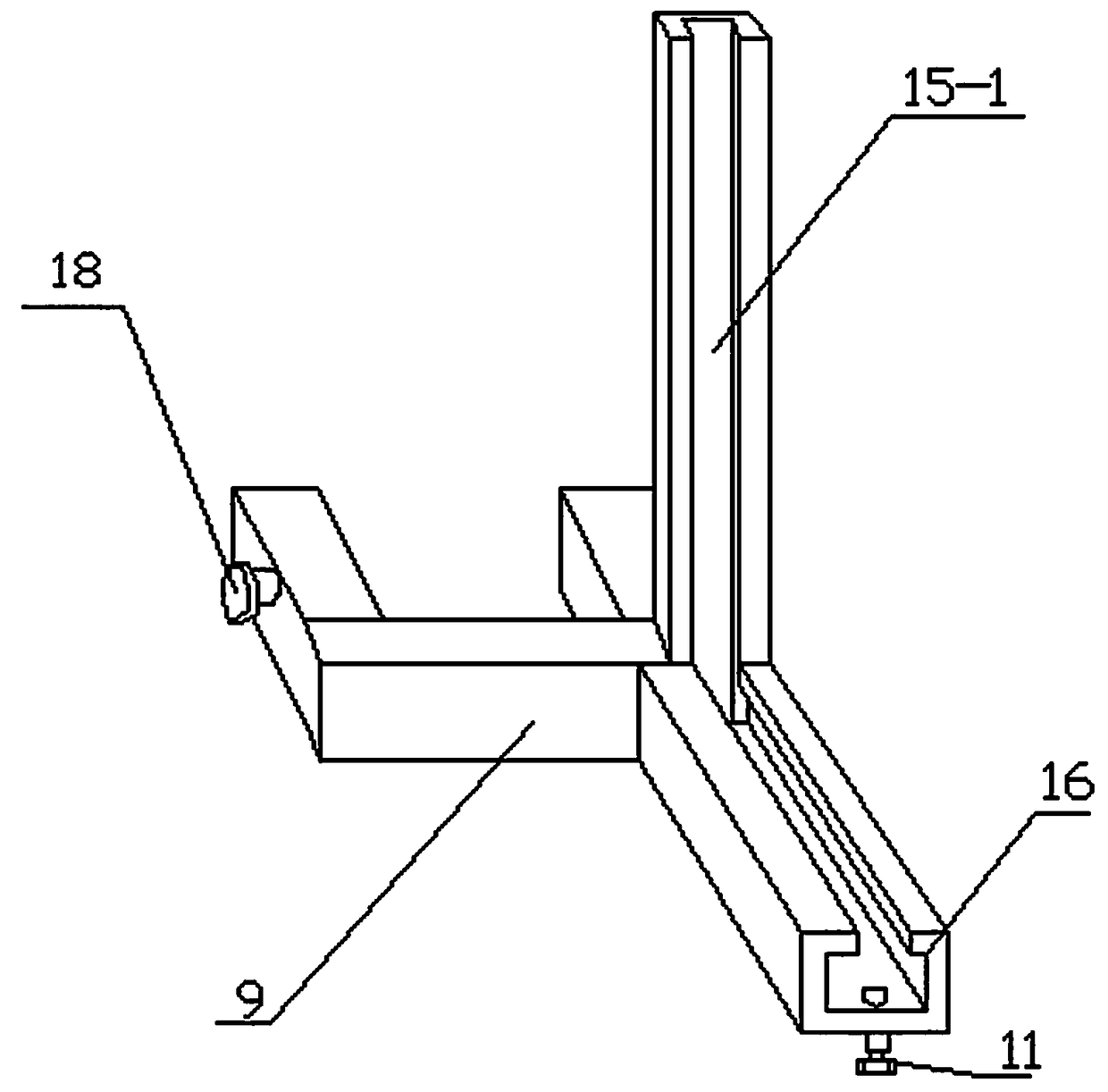

[0028] as attached figure 1 and 2 As shown, a high-frequency partial discharge measurement position marking tool includes a base 1, a traveling universal wheel 2 arranged at the bottom of the base 1, a rack-shaped bracket 3 arranged on the top of the base 1, and a rack-shaped bracket 3 arranged on the bottom of the base 1 The gear 4 on the left, the gear shaft 6 arranged at the axial center of the gear 4, the sleeve 5 and the rotating handle 7 arranged on the gear shaft 6 and the special-shaped frame arranged between the gear 4 and the "L" frame 10 9. The gear shaft 6 and the shaft sleeve 5 are connected by clearance fit, the rotary handle 7 is fixedly connected with the gear shaft 6, and the special-shaped frame 9 is fixedly connected with the shaft sleeve 5; the "L"-shaped frame 10 is provided with a guide groove 15-2 , the upper part of the "L"-shaped fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com