Worker-finding-by-cargo management method for e-commerce automatic storage and distribution

A warehousing and e-commerce technology, applied in the field of warehousing and logistics, can solve the problems of large differences in size, shape, softness and hardness, serious waste and pollution, and the need for a lot of labor. It is easy to automate, eliminate labor, and eliminate manual distribution vehicles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

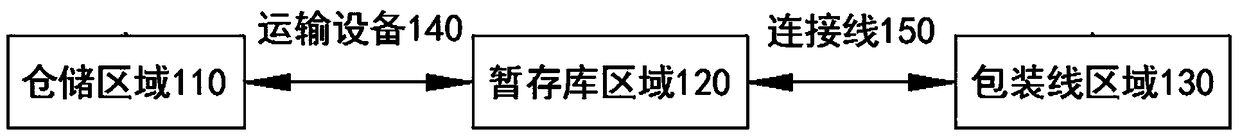

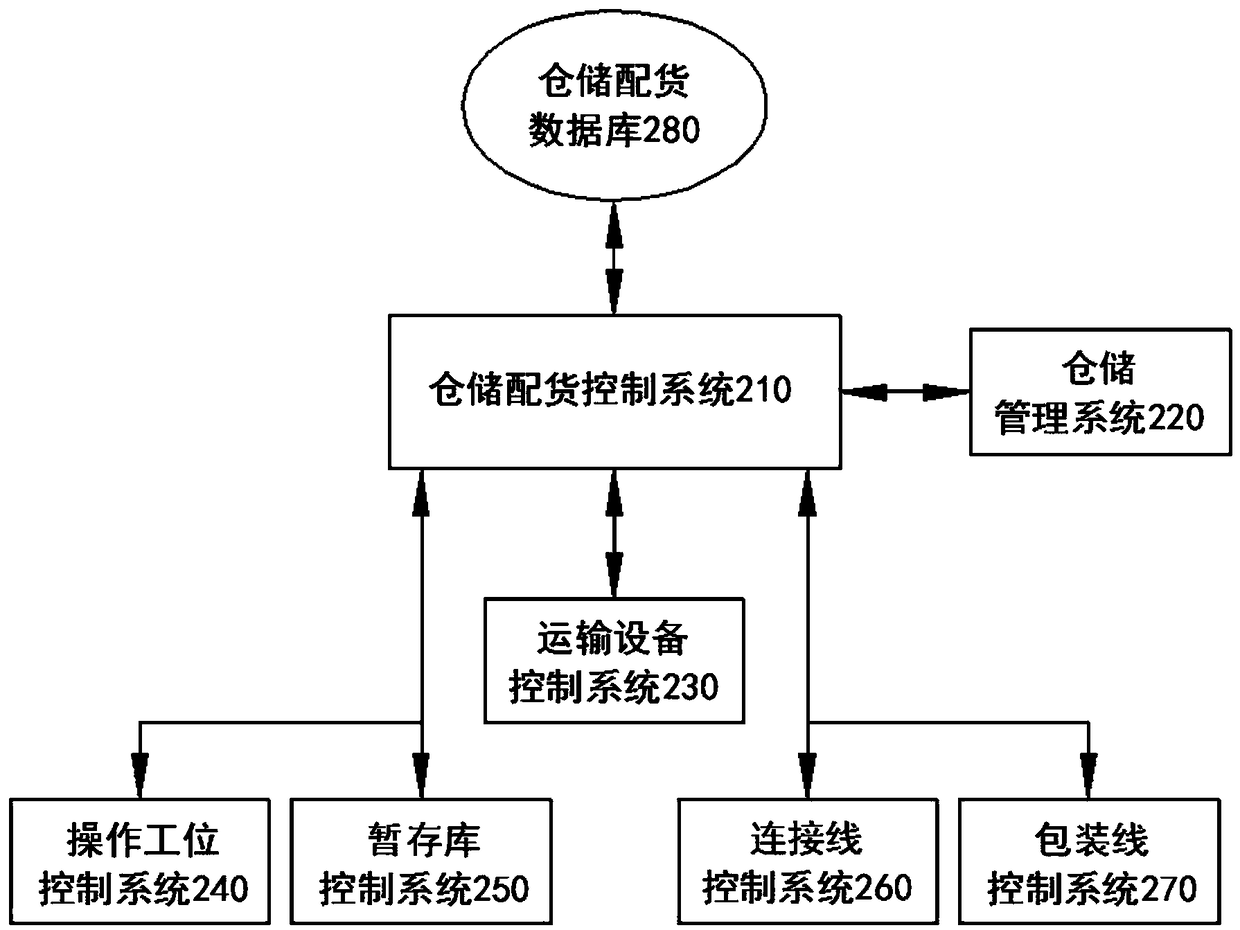

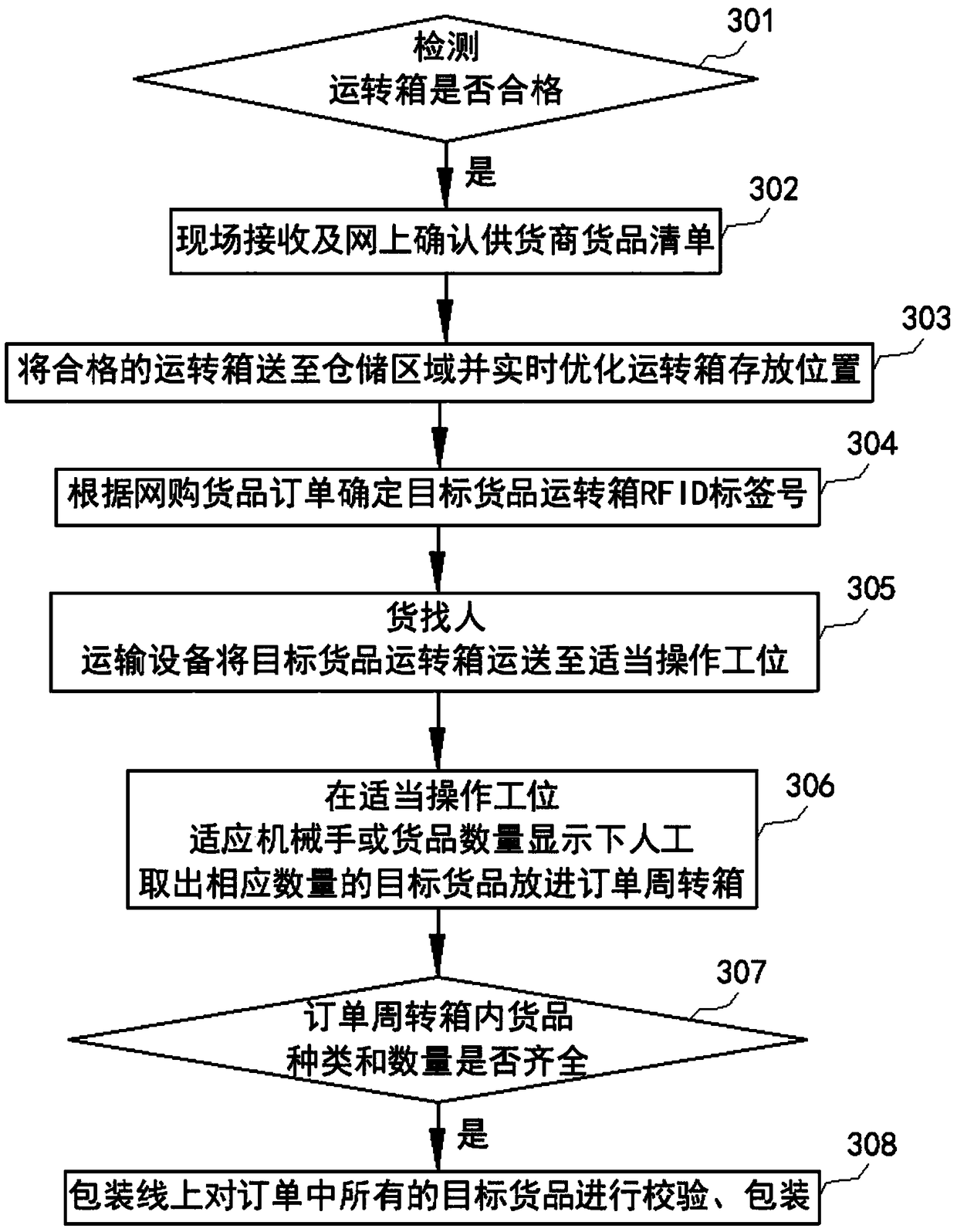

[0054] According to the embodiment of the present invention, the area division of the storage and distribution center corresponding to the management method of finding people for the automatic storage and distribution of e-commerce, as shown in the attached figure 1 As shown, the warehouse distribution center includes a storage area 110, a temporary storage area 120, a packaging line area 130, a transportation device 140 for transporting the turnover boxes, and a connecting line 150 for transporting the order turnover boxes. Between the storage area 110 and the temporary storage area 120, the operation box is transported by the transportation equipment 140; the temporary storage area 120 contains two parts of the manipulator and the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com