Lithium battery soft pack fixing method and device

A fixing device and fixing method technology, applied in the direction of assembling battery machines, secondary battery manufacturing, battery pack components, etc., can solve the problems of large factors affecting product quality, different welding levels of workers, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

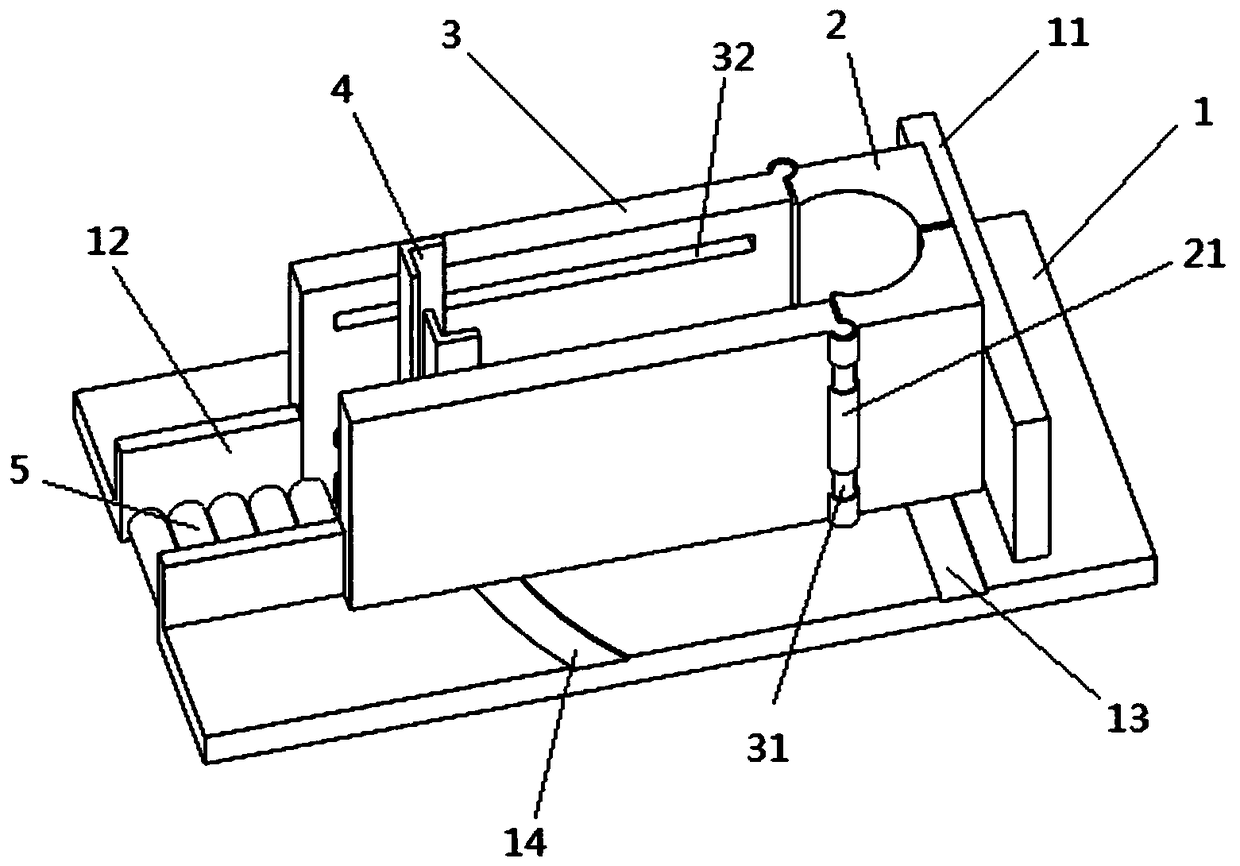

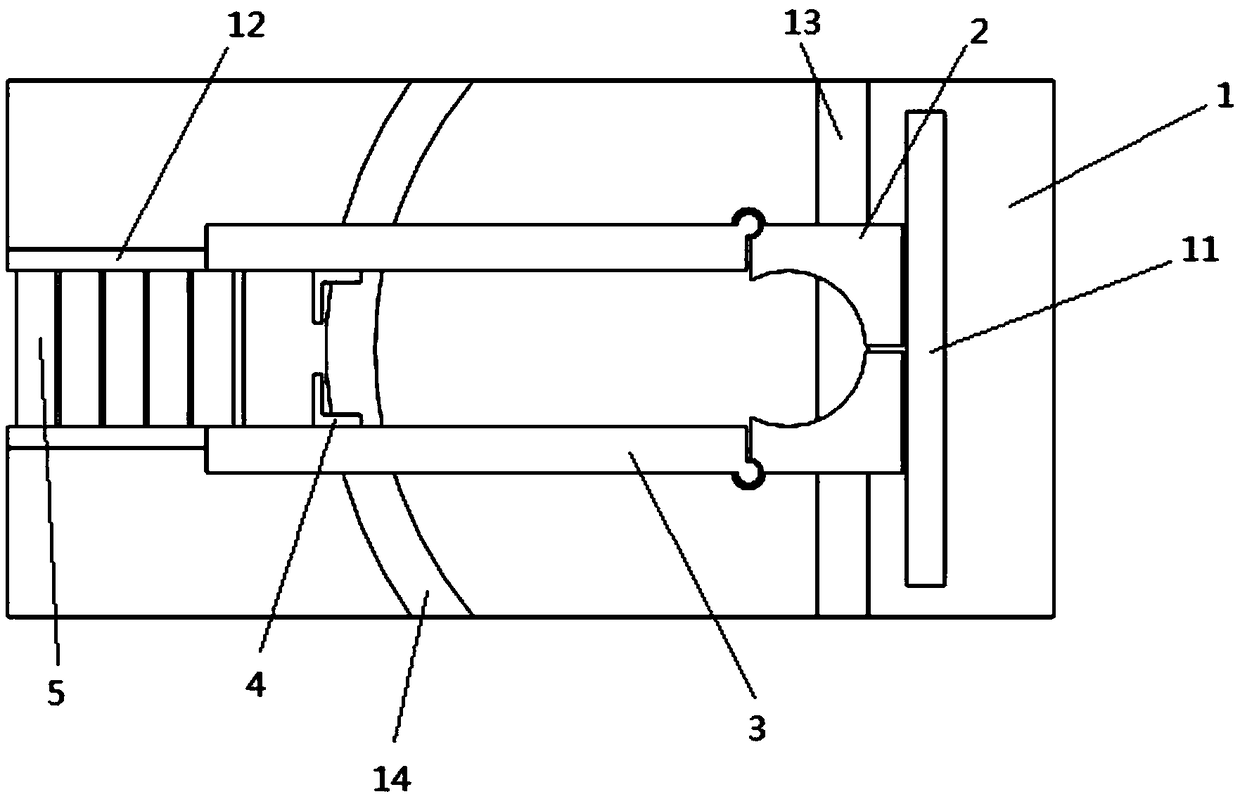

[0026] The purpose of the present invention can be achieved through the following technical solutions:

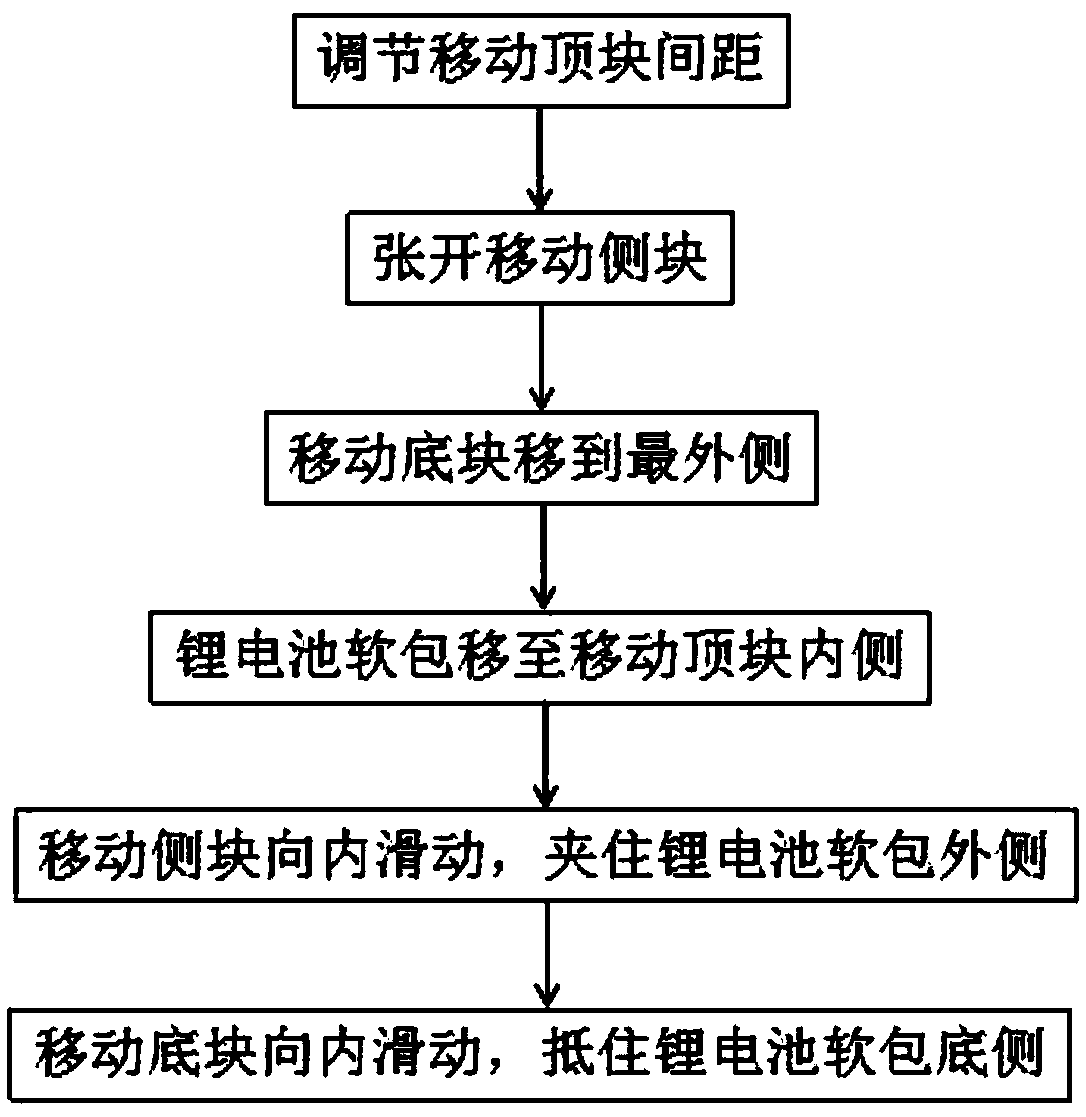

[0027] A kind of lithium battery soft pack fixing method, see figure 1 , including the following steps:

[0028] Step 1. According to the size of the lithium battery soft pack, move the two front-end fixing blocks 2 along the front block sliding groove 13, and adjust the distance between the two front-end fixing blocks 2, so that the two front-end fixing blocks 2 can accommodate the size of the lithium battery soft pack;

[0029] Step 2: Rotate the side end fixing block 3 around the front block hinge sleeve 21, and the side end fixing block 3 slides outward along the side block sliding groove 14, so that the side end fixing block 3 opens; the rear end fixing block 4 moves along the rear block The sliding groove 32 slides outward, so that the rear end fixing block 4 is located at the outermost side of the rear block sliding groove 32;

[0030] Step 3: Put the lithium batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com