A vertical beam and a refrigerator equipped with the vertical beam

A vertical beam and installation structure technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of affecting the appearance of vertical beams, prone to deformation, poor overall rigidity, etc. The effect of stiffness and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

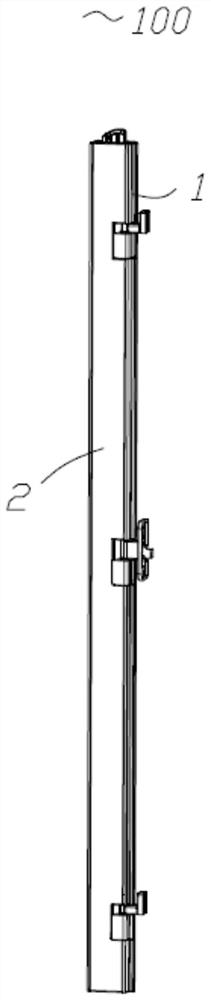

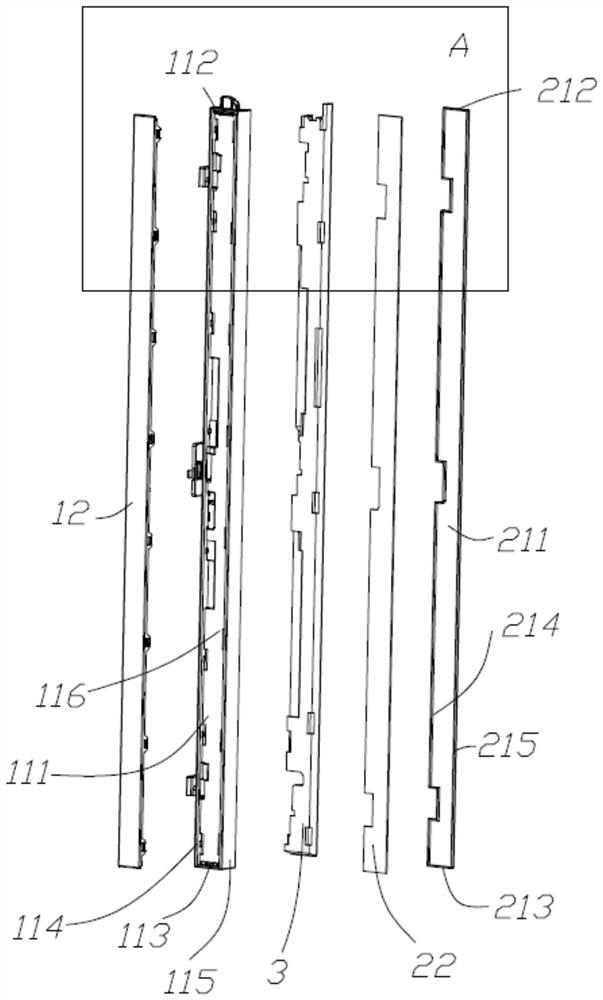

[0021] Such as Figure 1 to Figure 4 As shown, the vertical beam 100 of the present invention includes a front shell 1 opening to the rear, a rear plate 2 that covers the opening and cooperates with the front shell 1, and defines a gap between the front shell 1 and the rear plate 2. In addition to the foaming space, the vertical beam 100 also includes an insulating layer 3 located in the foaming space. The rear plate 2 is directly covered on the front shell 1, which reduces the gap generated during installation, makes the overall structure of the vertical beam 100 more beautiful, and is not easy to accumulate dust, ensuring the safety of the vertical beam 100. Clean and hygienic.

[0022] The front shell 1 includes a vertical beam body 11 openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com