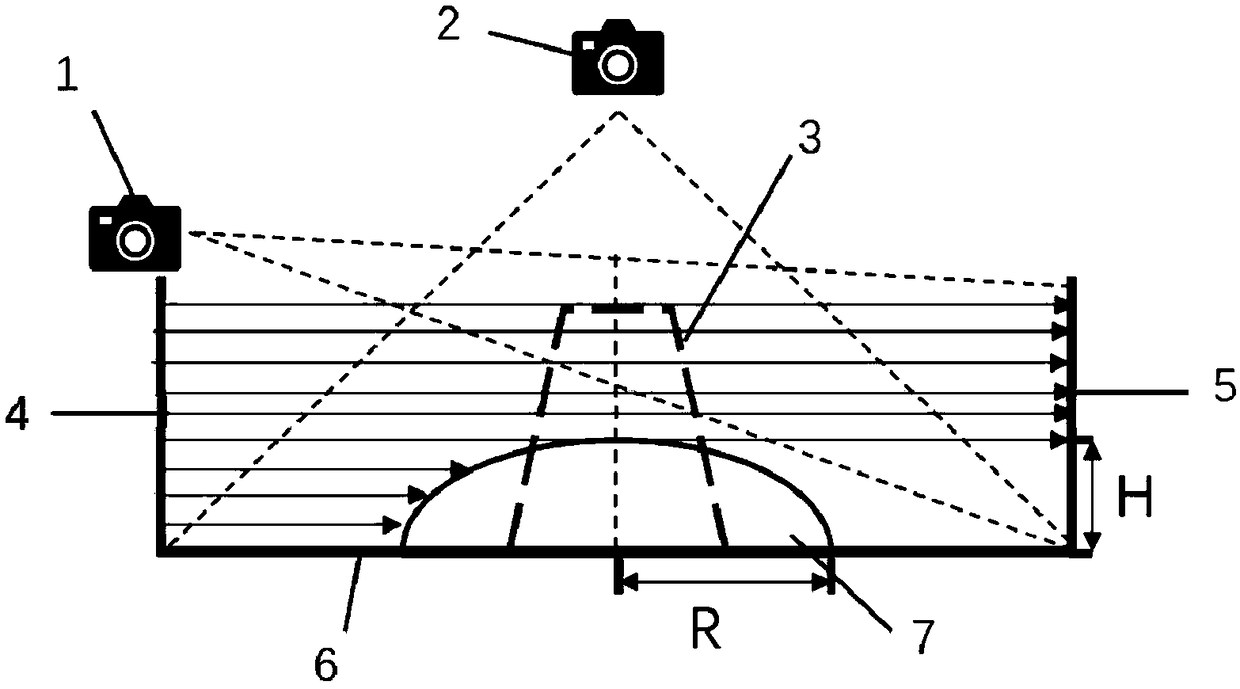

Method for predicting rheological parameters of fresh concrete through slump test

A testing process and slump technology, applied in the directions of flow characteristics, measuring devices, instruments, etc., can solve the problems of difficult to carry out testing, complicated operation, unable to fully reflect the working performance of concrete, etc., to reduce the testing cost and simplify the testing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The test process of using the above-mentioned device of the present invention to test rheological parameters is:

[0062] (1) Place the square bottom plate on a horizontal surface;

[0063] (2) Fix the vertical rectangular plate on the opposite sides of the square bottom plate, and the long sides of the vertical rectangular plate are aligned with the sides of the square bottom plate to keep it perpendicular to the square bottom plate;

[0064] (3) Combine the two halves of the slump cylinder to form a complete slump cylinder and place it in the center of the right-shaped bottom plate so that the axis of the detachable slump cylinder coincides with the center of the square bottom plate;

[0065] (4) Turn on the parallel dot matrix light source, the first camera and the second camera;

[0066] (5) Pouring fresh concrete into the complete detachable slump cylinder;

[0067] (6) Separate the two halves of the detachable slump cylinder to both sides at the same time, and the concrete b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com