Steel plate drilling equipment

A technology for punching equipment and steel plates, which is used in drilling/drilling equipment, metal processing equipment, measuring/indicating equipment, etc. hole precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

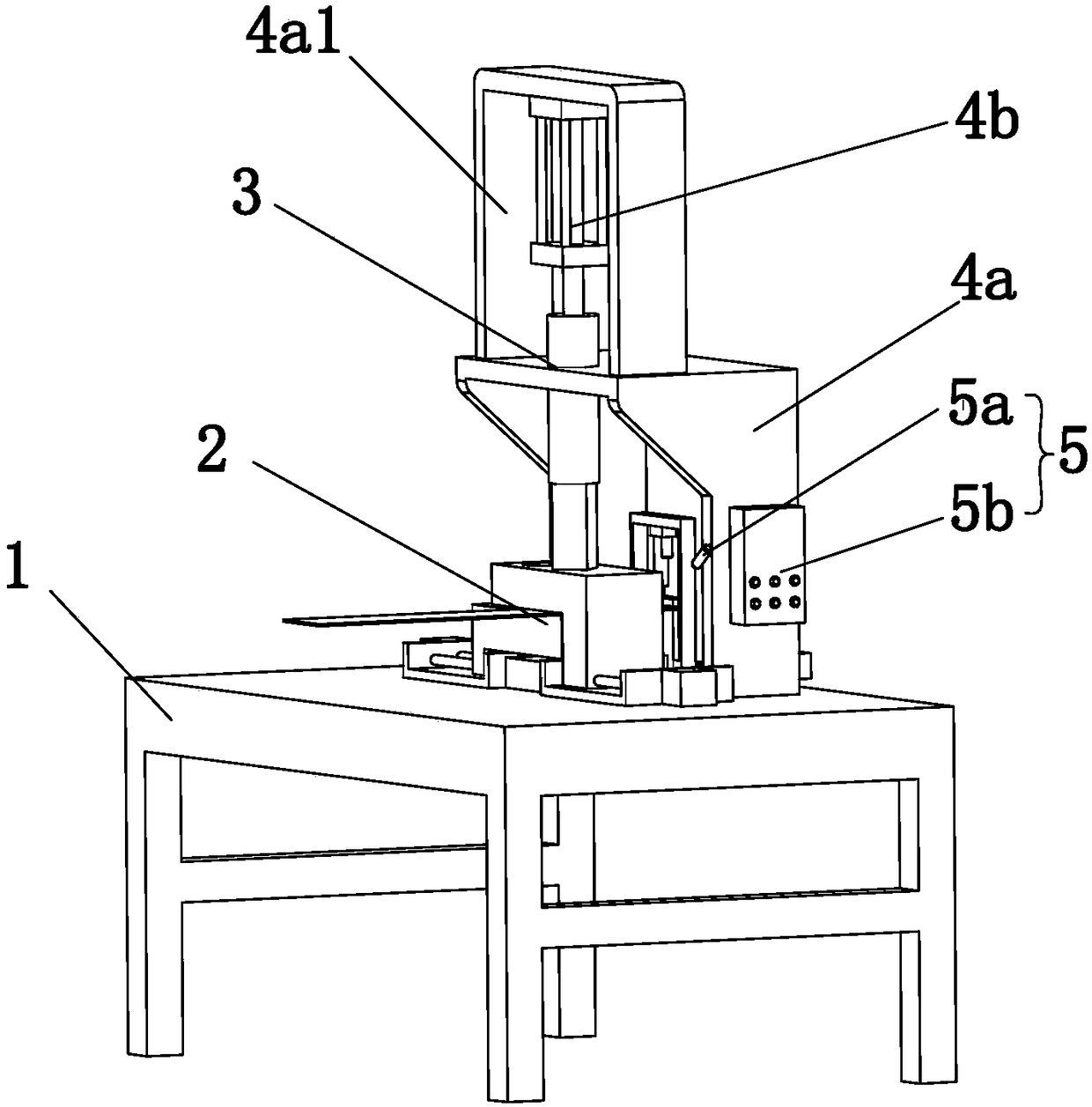

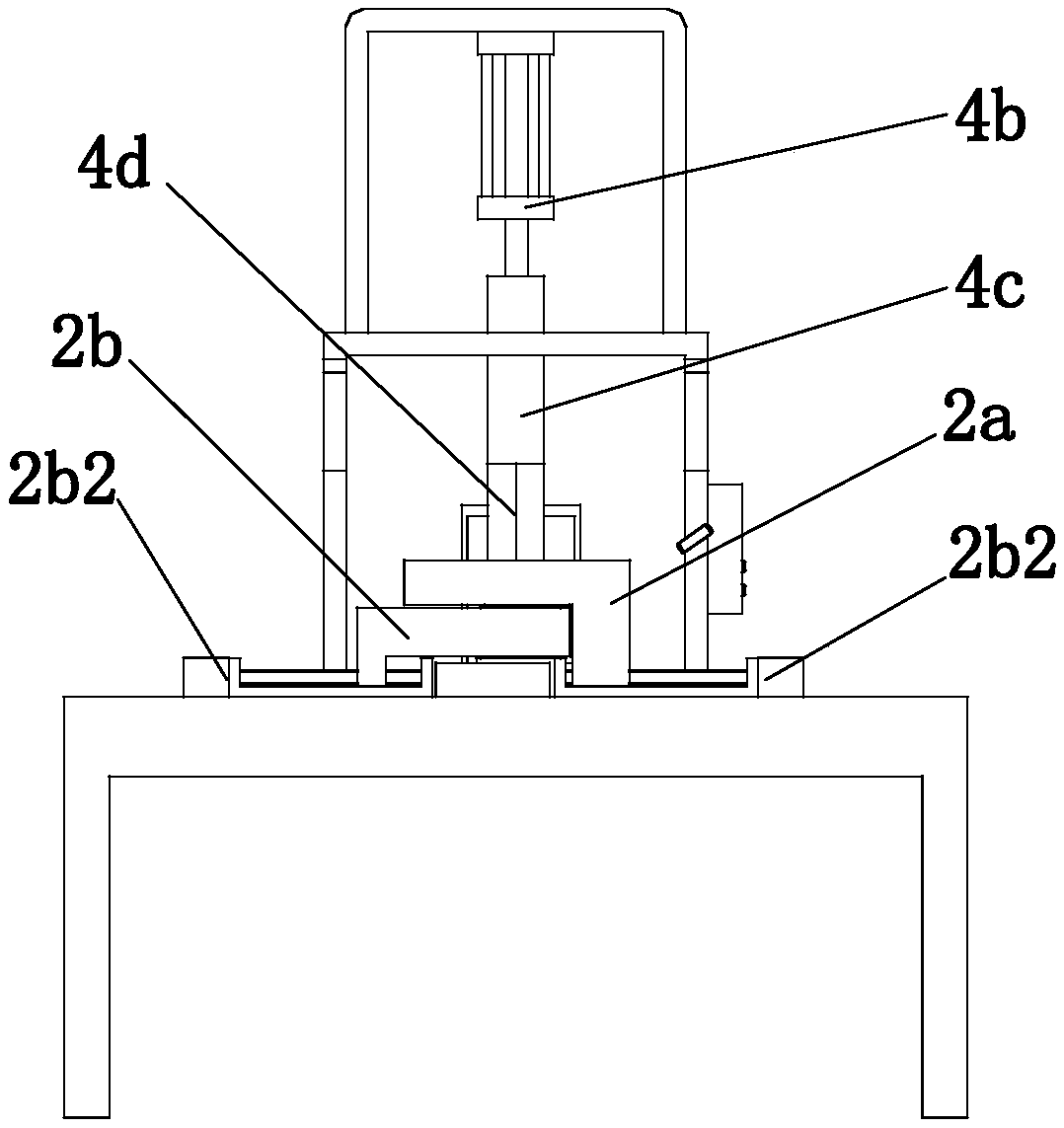

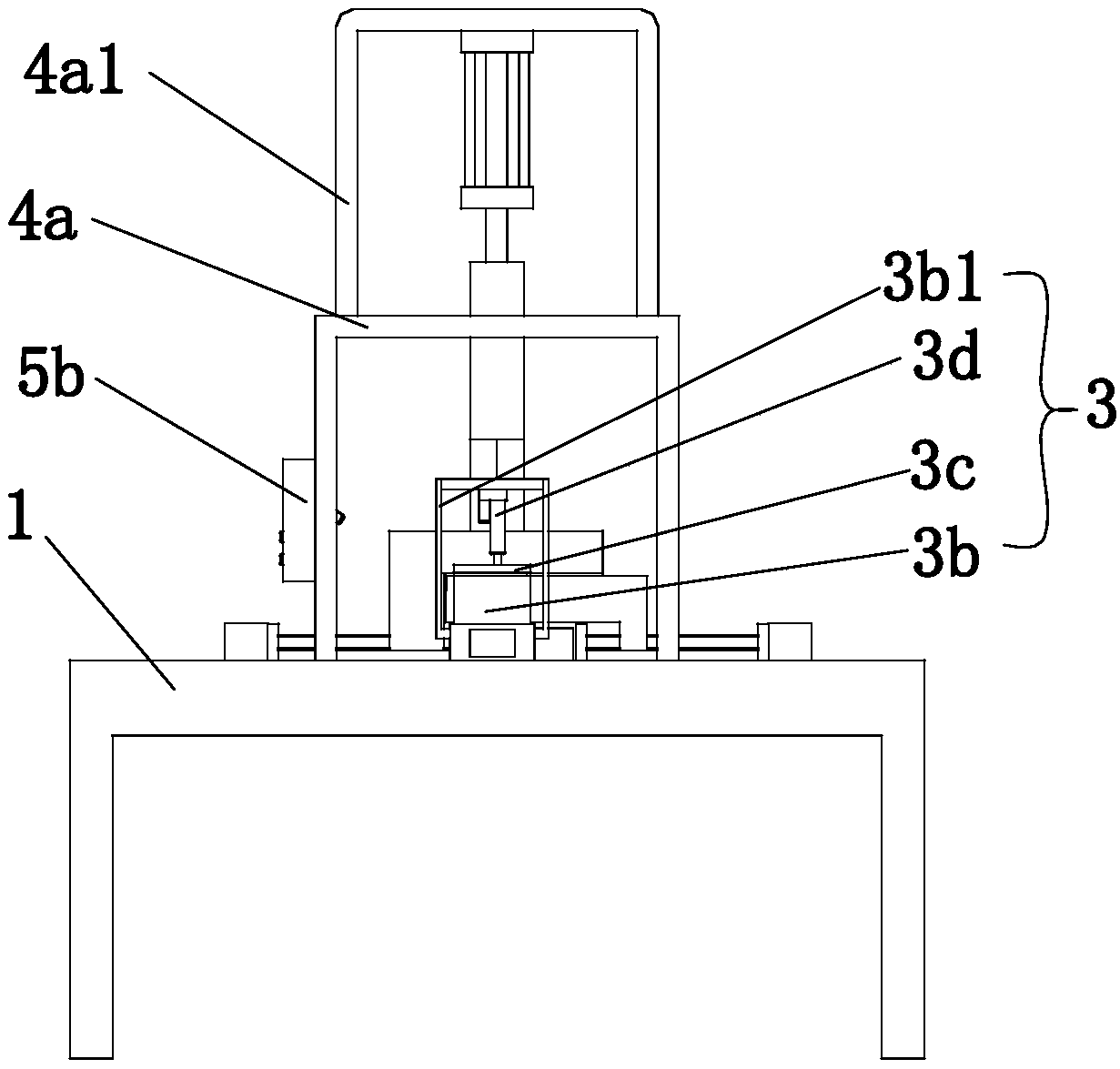

[0020] refer to Figure 1 to Figure 5 A steel plate punching equipment shown includes a base 1, a fixing mechanism 2, a clamping mechanism 3, a punching mechanism 4 and a control system 5, the fixing mechanism 2 is arranged on the base 1, and the fixing mechanism 2 is provided with a first Fixed block 2a and the second fixed block 2b, the first fixed block 2a is arranged on the second fixed block 2b top, the punching mechanism 4 is arranged on the first fixed block 2a top, the punching mechanism 4 is provided with fixed frame 4a, cylinder 4b, The connecting column 4c and the drilling bit 4d, the fixed frame 4a is an inverted U-shaped support, the two ends of the fixed frame 4a are arranged on the base 1, the cylinder 4b is arranged above the fixed frame 4a, and one end of the connecting column 4c is connected to the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap