Clamping structure of industrial robot

A technology of industrial robots and clamping structures, applied in chucks, manipulators, manufacturing tools, etc., can solve problems such as low firmness of workpieces, poor processing quality, and small application range, so as to improve clamping quality and work efficiency , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

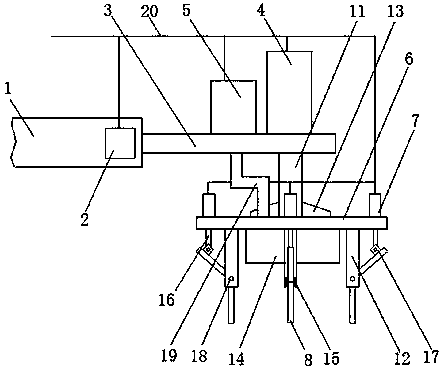

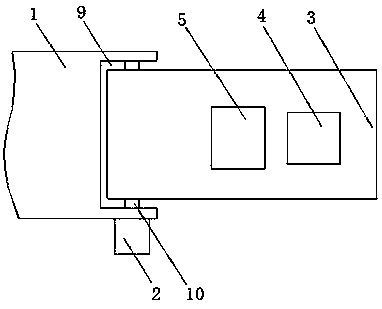

[0019] as attached figure 1 with 2 As shown, a clamping structure of an industrial robot includes a positioning plate 1, a motor 2, a load plate 3, a cylinder one 4, a vacuum pump 5, a fixed plate 6, a cylinder two 7 and a clamping rod 8, and is characterized in that: The positioning plate 1 is provided with a limiting groove 9, the motor 2 is arranged on the positioning plate 1, a rotating shaft 10 is arranged on the motor 2, and the rotating shaft 10 is arranged in the limiting groove 9, the described One end of the bearing plate 3 is connected with the rotating shaft 10, the cylinder one 4 is arranged on the bearing plate 3, and the piston rod one 11 is arranged on the cylinder one 4, the described vacuum pump 5 is arranged on the bearing plate 3, and Vacuum pump 5 is provided with suction pipe 19, and described fixed plate 6 is arranged on the piston rod one 11, is provided with fixed rod 12, reinforcing plate 13, suction hood 14 on fixed plate 6, and on fixed rod 12 is ...

Embodiment 2

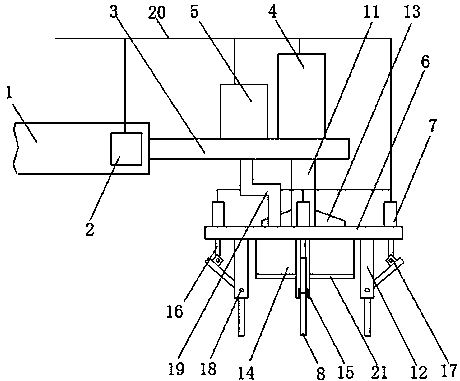

[0027] as attached image 3 As shown, a clamping structure of an industrial robot includes a positioning plate 1, a motor 2, a load plate 3, a cylinder one 4, a vacuum pump 5, a fixed plate 6, a cylinder two 7 and a clamping rod 8, and is characterized in that: The positioning plate 1 is provided with a limiting groove 9, the motor 2 is arranged on the positioning plate 1, a rotating shaft 10 is arranged on the motor 2, and the rotating shaft 10 is arranged in the limiting groove 9, the described One end of the bearing plate 3 is connected with the rotating shaft 10, the cylinder one 4 is arranged on the bearing plate 3, and the piston rod one 11 is arranged on the cylinder one 4, the described vacuum pump 5 is arranged on the bearing plate 3, and Vacuum pump 5 is provided with suction pipe 19, and described fixed plate 6 is arranged on the piston rod one 11, is provided with fixed rod 12, reinforcing plate 13, suction hood 14 on fixed plate 6, and on fixed rod 12 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com