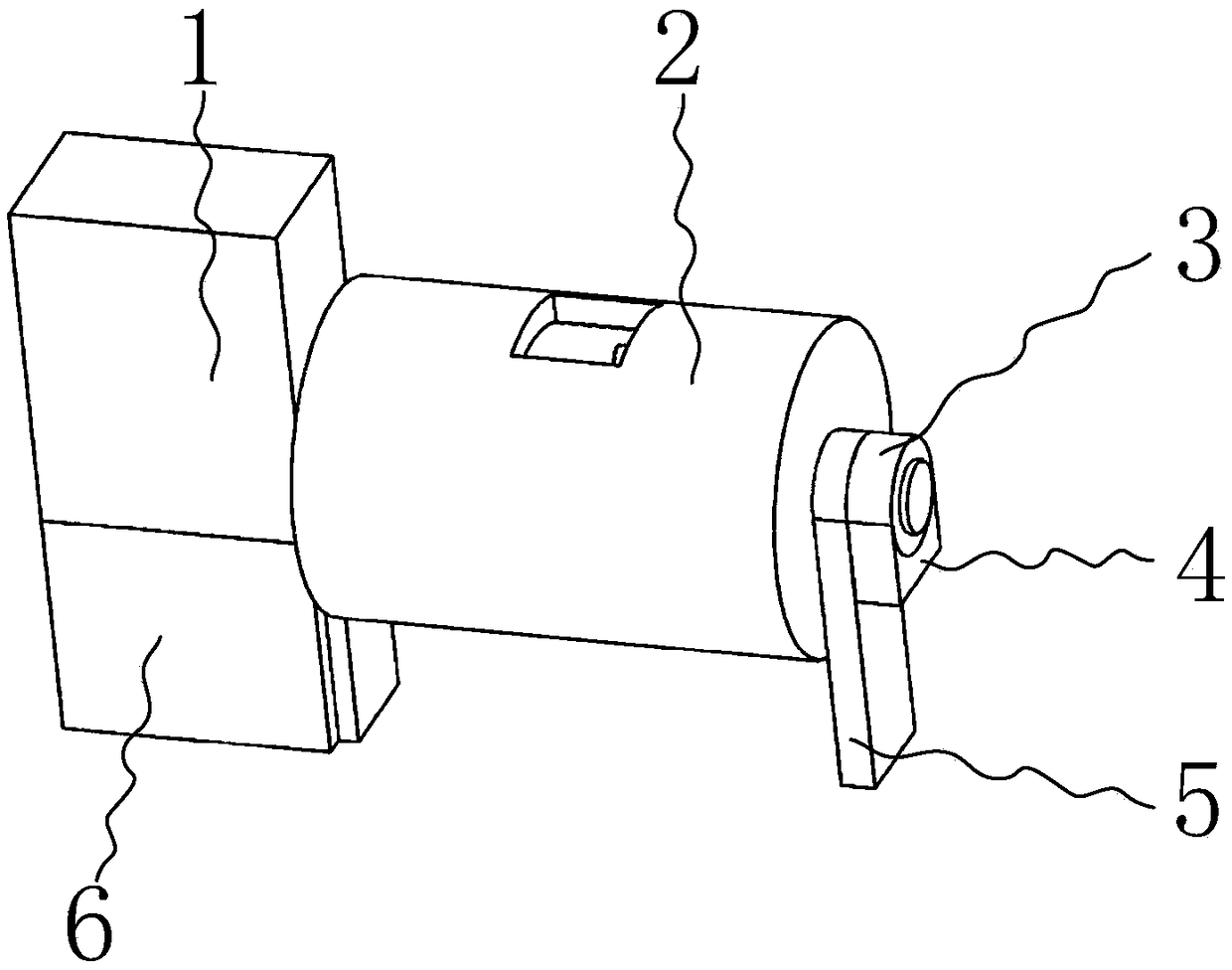

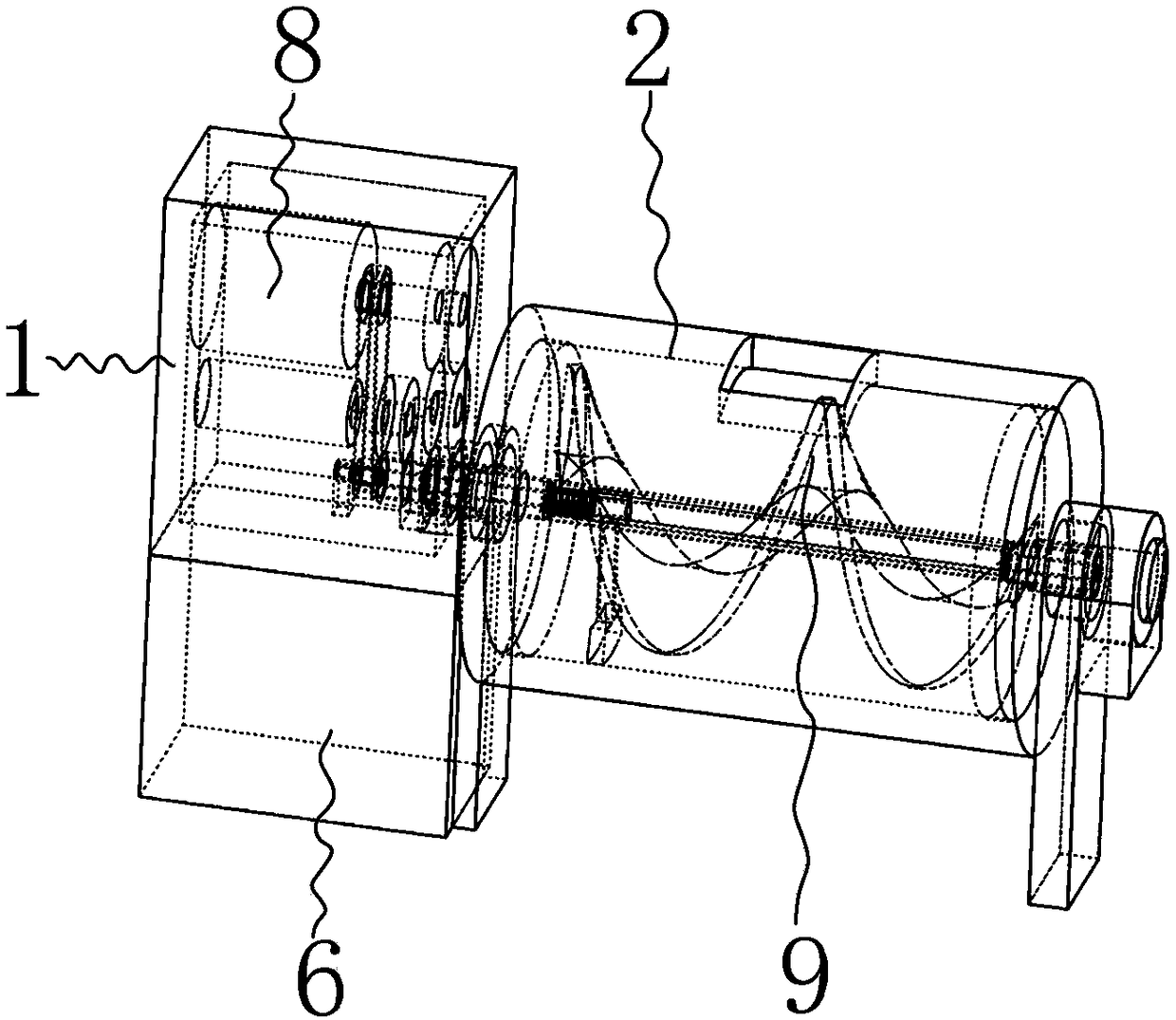

Concrete mixer used for municipal construction engineering and based on spiral sheets

A technology for concrete mixers and construction engineering, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., and can solve problems such as the influence of the overall quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

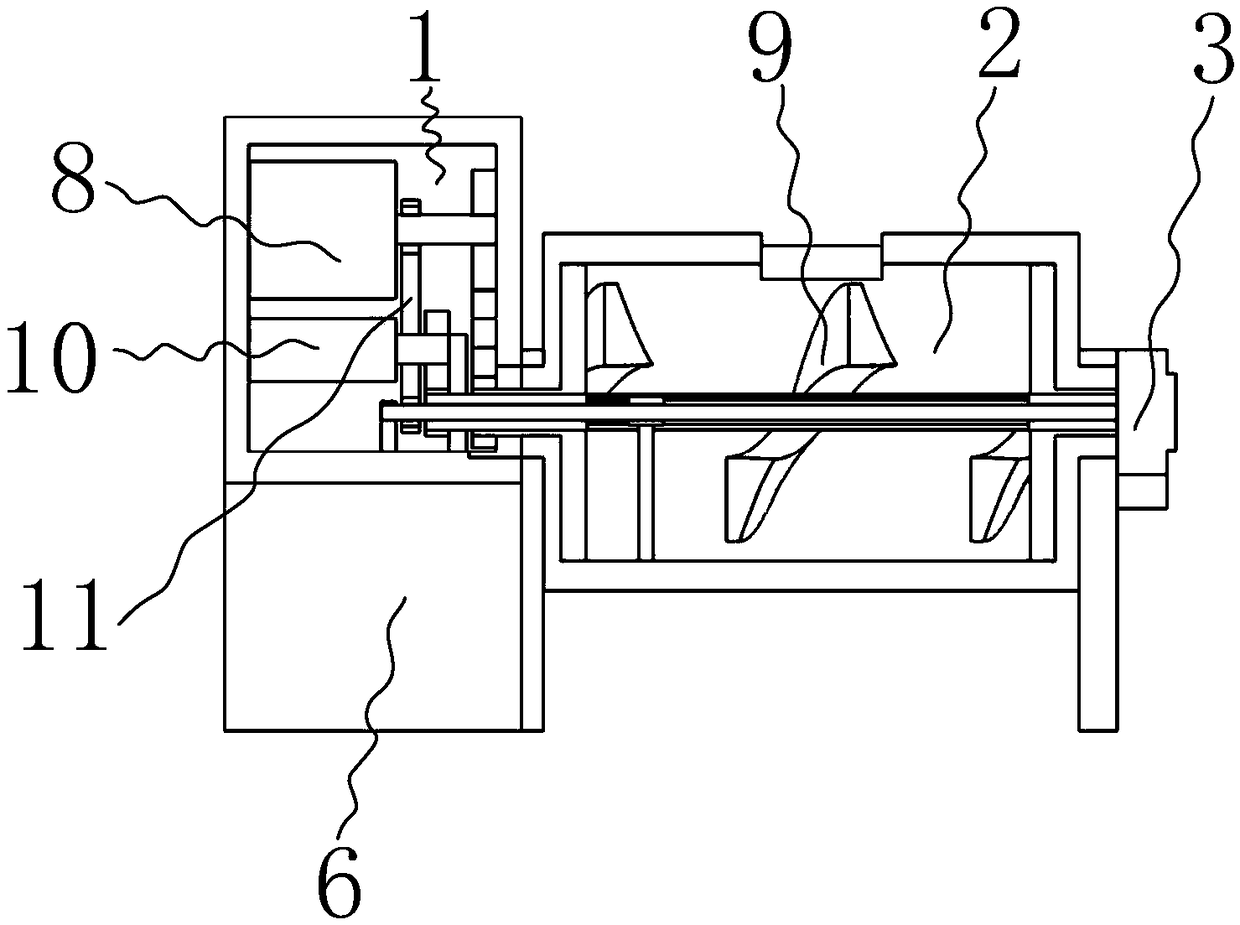

specific Embodiment approach

[0055] The specific embodiment: when using the mixer designed by the present invention, before use, the filling port 32 opened on the mixing shell 2 is turned upward by the adjusting mechanism 3; The filling port 32 is put into the stirring shell 2; after the loading is completed, the first drive motor 8 is controlled to work, and the first drive motor 8 will drive the first rotating shaft 19 to rotate through the output shaft on it; the first rotating shaft 19 rotates to drive the installation The second gear 13 on it rotates; the second gear 13 rotates to drive the first gear 12 meshed with it to rotate; the first gear 12 rotates to drive the fourth gear 17 meshed with it to rotate; the fourth gear 17 rotates through the corresponding first gear The shaft sleeve 25 drives the corresponding fixed ring 15 to rotate; the fixed ring 15 rotates to drive the spiral stirring blade 9 to rotate. The concrete raw material is stirred by the rotation of the spiral stirring blade 9; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com