Clamping-type transport vehicle

A transport vehicle and clamping technology, which is applied in the direction of parallel load-carrying vehicles, etc., can solve the problems of high chassis, increased management and economic costs, and low work efficiency, so as to reduce the handling height, improve work efficiency and safety , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

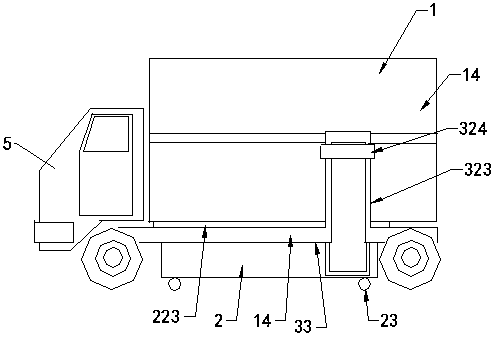

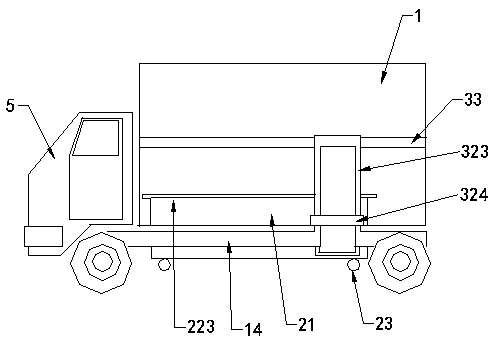

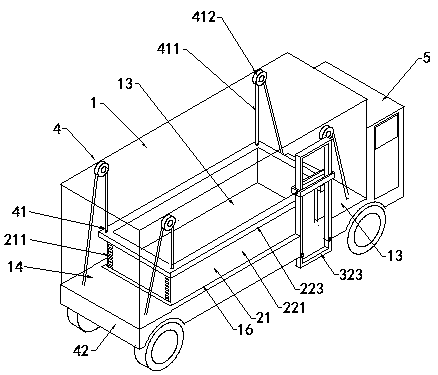

[0027] see Figure 1 to Figure 7 , a clamping transport vehicle, including a front 5, a car body 1, a loading compartment frame 2, a clamping mechanism 3, and a lifting mechanism 4.

[0028] 1. Box frame.

[0029] Such as figure 1 image 3 Figure 8 As shown, the box frame includes a fixed base frame 14 and a telescopic base frame 15. The fixed base frame is horizontally fixedly connected by connecting bars 33 perpendicular to each other to form a fixed clamping opening 16. The clamping opening is rectangular, and its vertical wall forms The shape and size of the columnar opening of the loading compartment correspond to the columnar box body of the vertical compartment 21 of the loading compartment frame. The vertical compartment is installed in the fixed clamping port 16 and can slide vertically up and down. The front and rear vertical surfaces of the fixed clamping port are provided with drive Gear shaft 141, its teeth are engaged with the teeth of the corresponding posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com