Crystalline silicon solar module packing box and packing method

A technology of solar modules and crystalline silicon, which is applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of low packing efficiency, high handling height, and high work intensity, and achieve reduced packing work intensity, reduced handling height, The effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

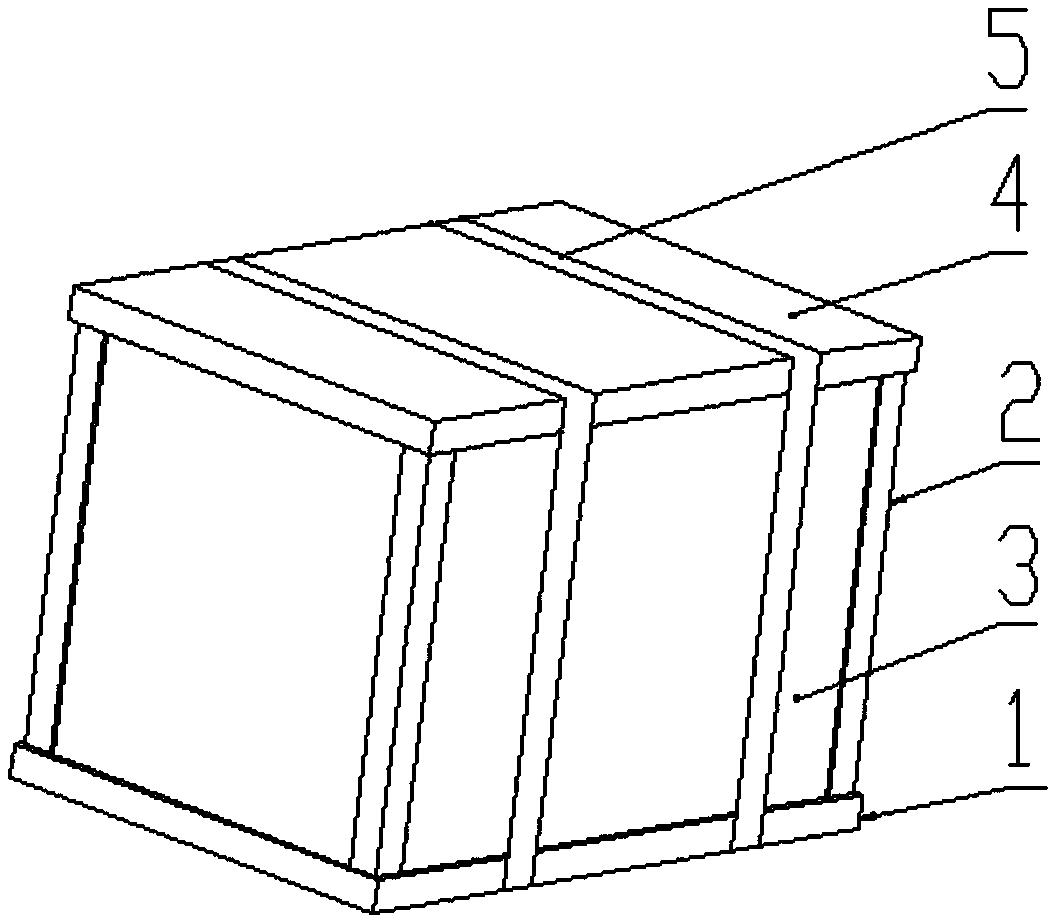

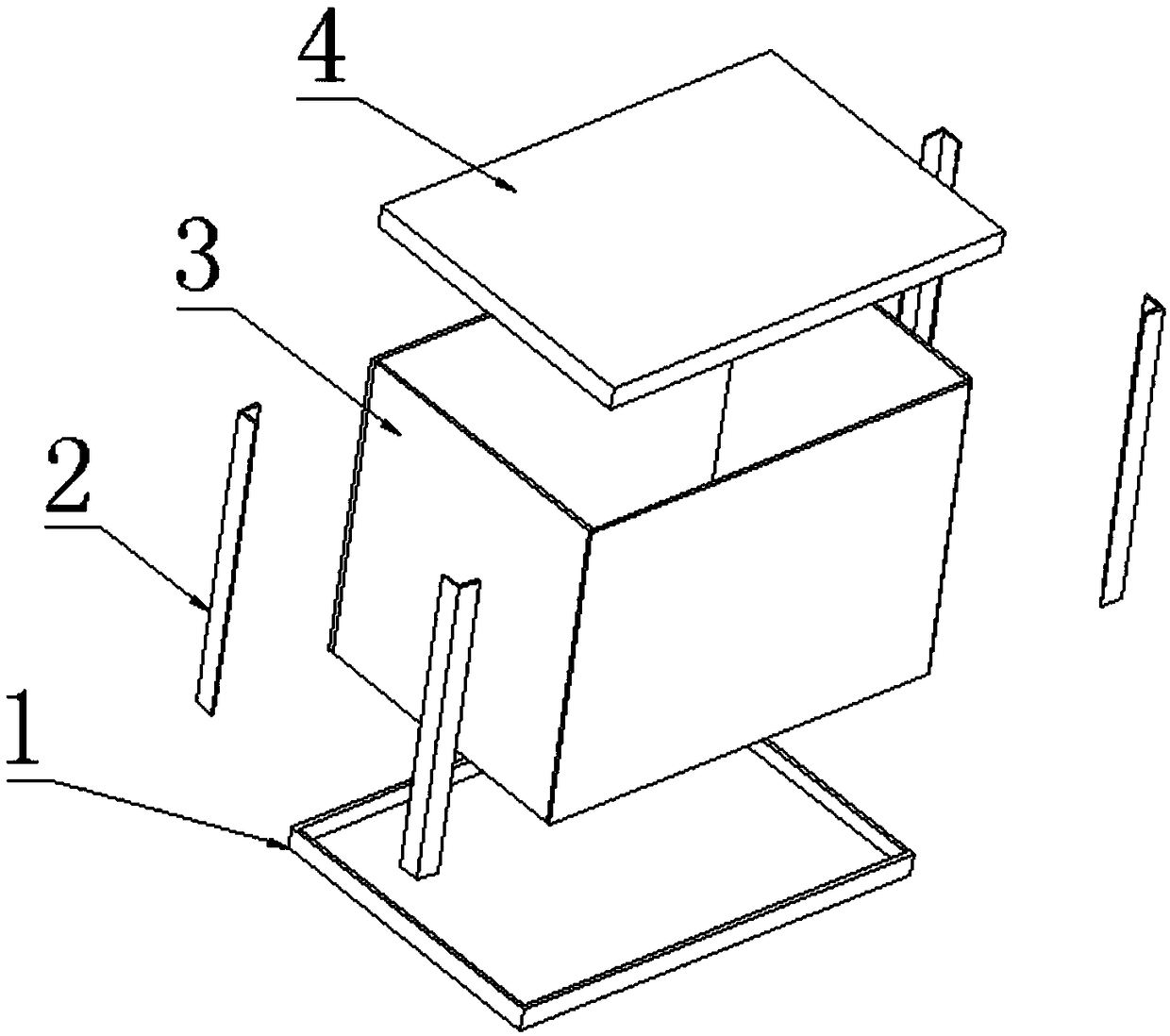

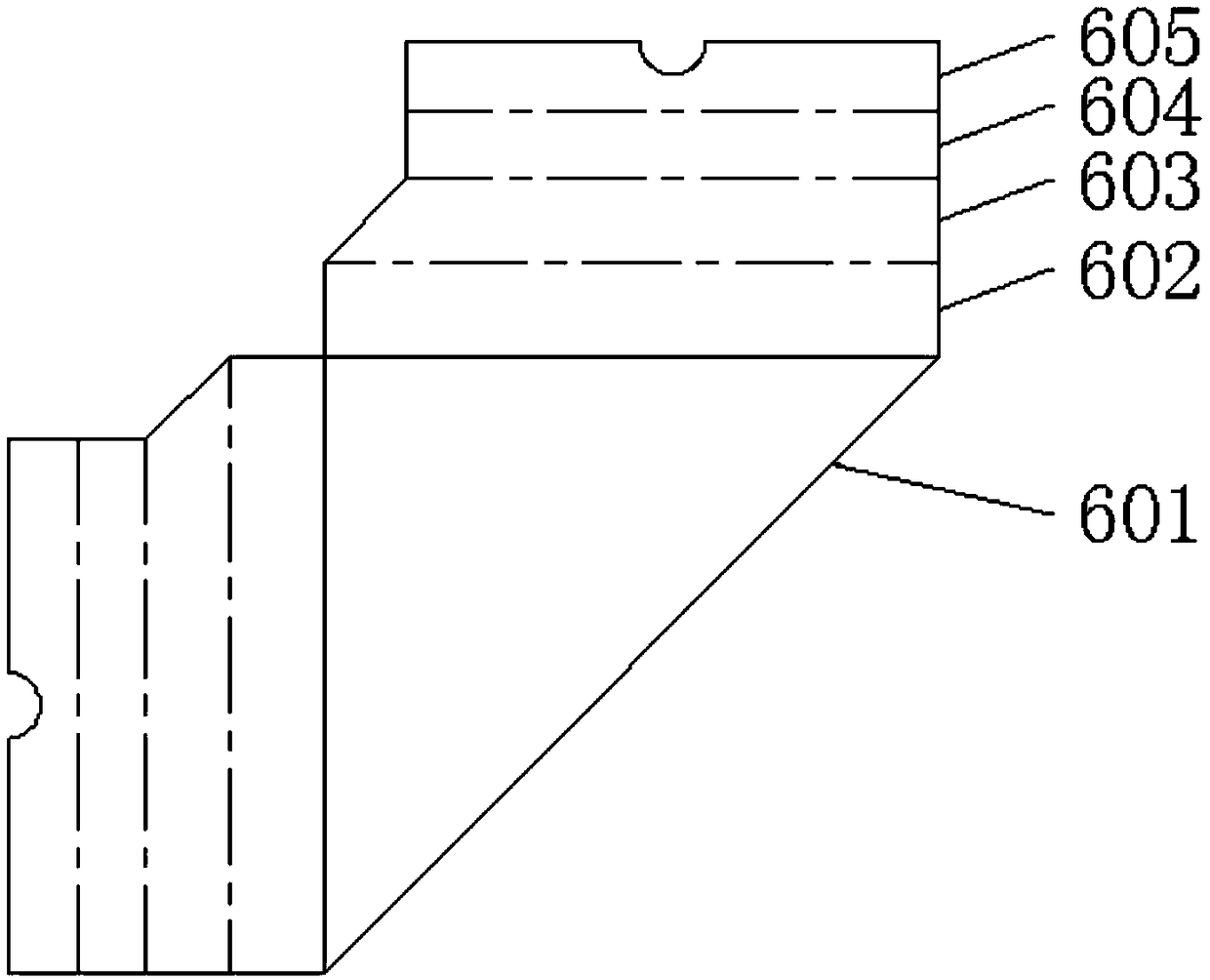

[0023] Such as Figure 1-Figure 4 As shown, the packaging box for crystalline silicon solar modules includes a tray 1, which is special in that: place right-angle guards 2 at the four corners of the tray 1, and place baffles 3 between two adjacent right-angle guards 2. The four baffles 3 are connected end to end, and the four end-to-end baffles 3 are located in the four right-angle guards 2, and the tops of the four right-angle guards 2 are covered with box covers 4, and the box covers 4 and the pallet 1 are packaged together. The belt 5 surrounds together; the crystalline silicon solar module packaging box is also provided with corner guards that buckle the four corners of a single solar module. The sides are sequentially connected to the first bent plate 602, the second bent plate 603, the third bent plate 604 and the fourth bent plate 605 from the inside to the outside, and the two first bent plates 602 after bending are connected and connected with each other. The angled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com