Fastening type forklift tray

A fastening type, forklift technology, used in rigid containers, containers, packaging and other directions, can solve the problems of affecting loading efficiency, fragile products can not play a good protective role, time-consuming and labor-intensive, etc., to achieve easy stacking, prevent Goods damaged, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

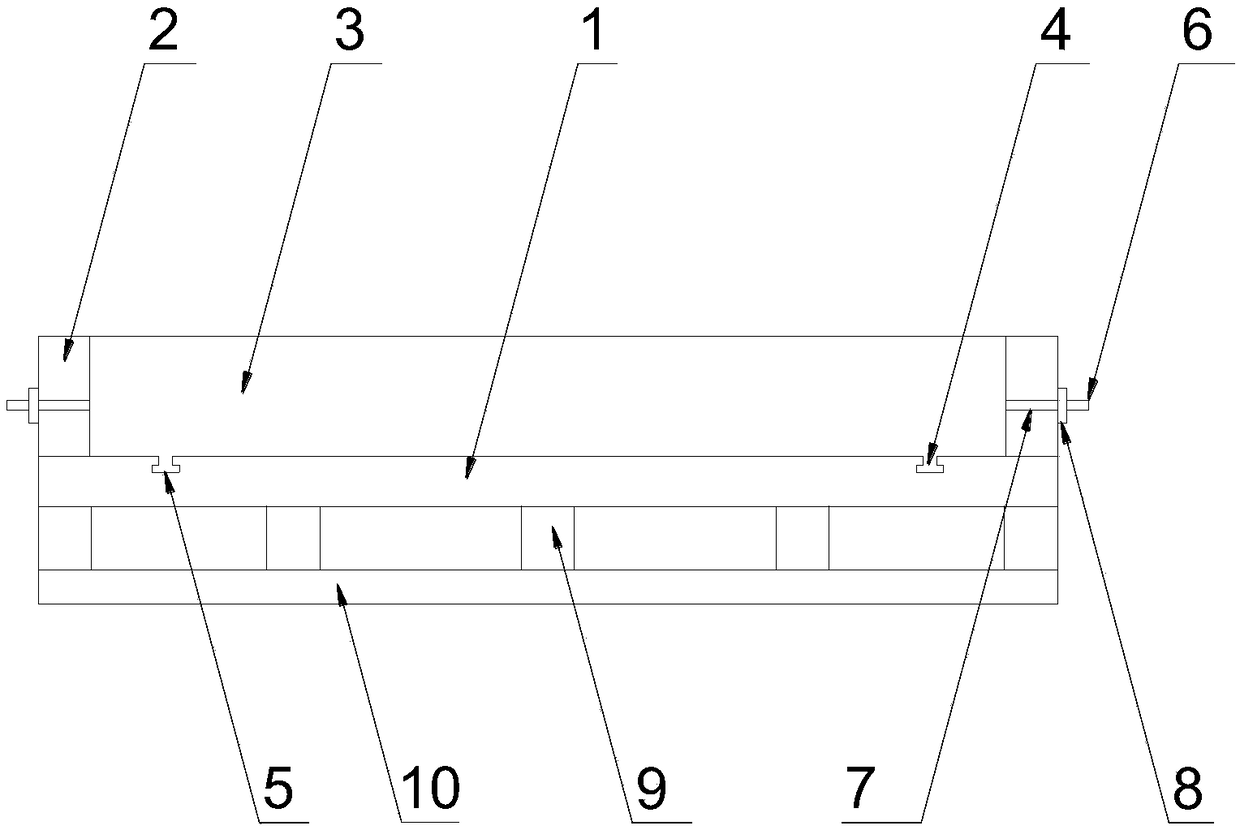

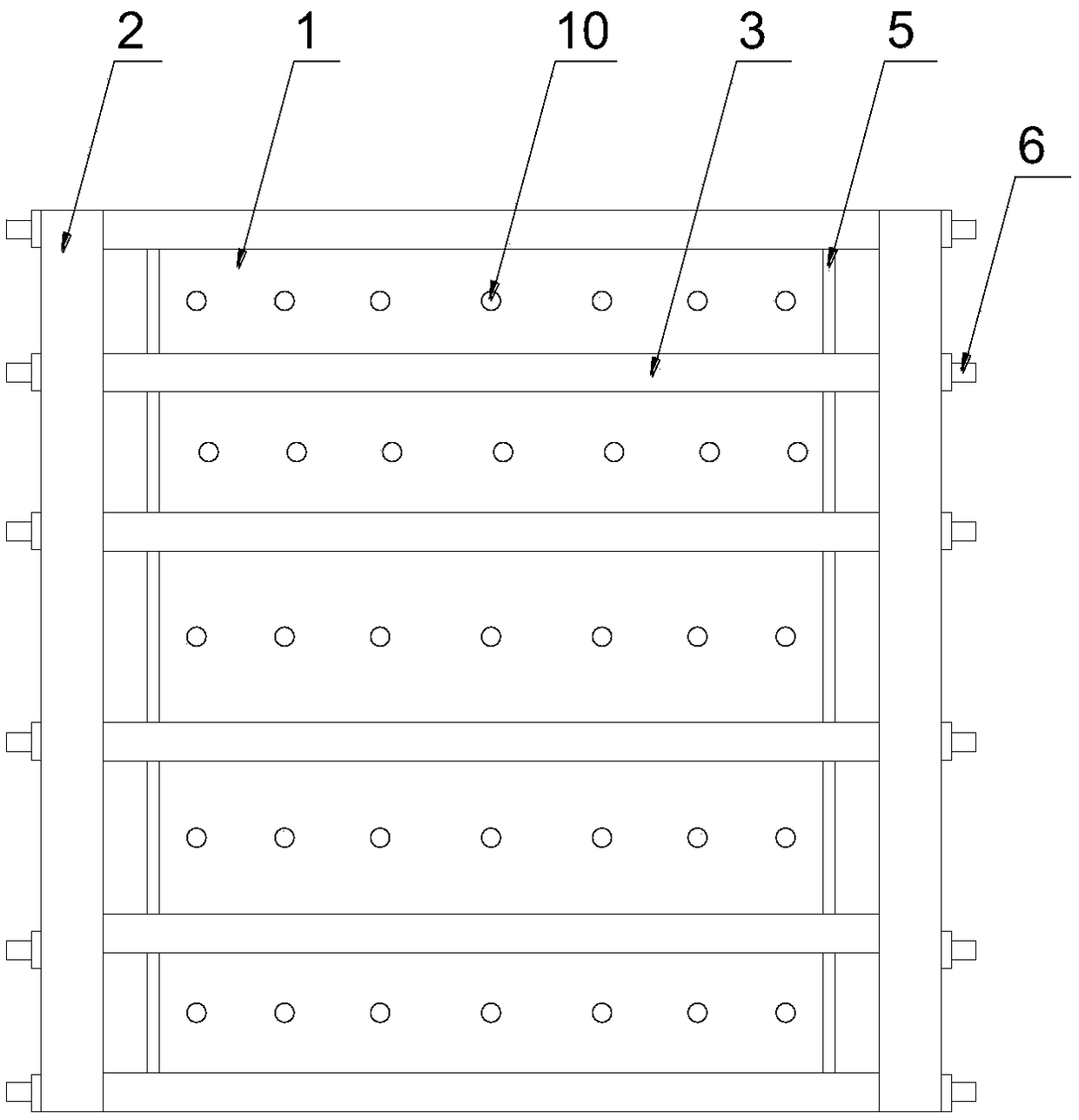

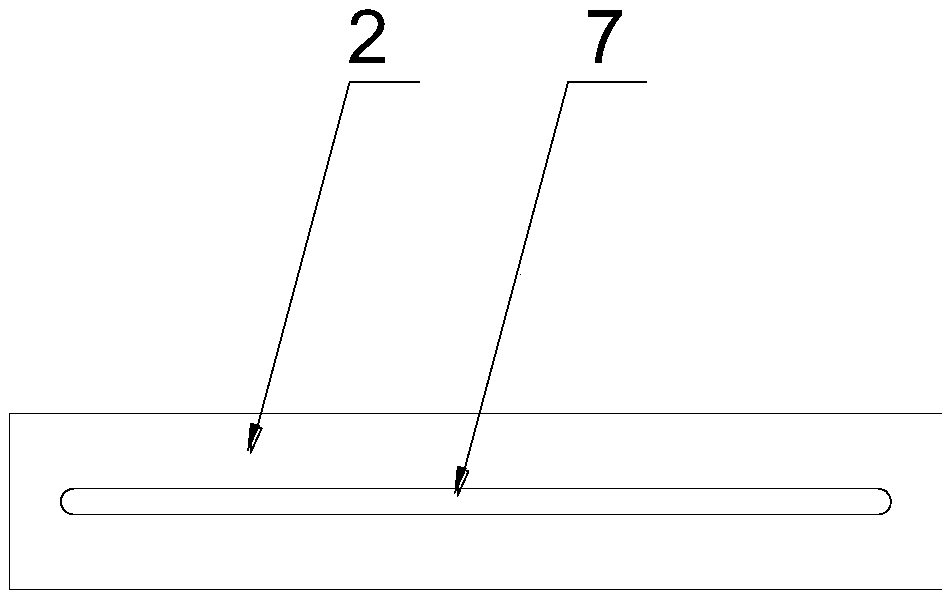

[0025] Such as Figure 1-3 as shown, figure 1 Front view of the fastened forklift pallet proposed by the present invention; figure 2 A top view of the fastened forklift pallet proposed by the present invention; image 3 It is a schematic diagram of the fixed plate in the fastened forklift pallet proposed by the present invention.

[0026] refer to Figure 1-3 , a fastening forklift pallet proposed by the present invention includes a base plate 1, two fixed plates 2, a plurality of moving plates 3, a screw rod 6, a lock nut 8 and a support column 9;

[0027] The base plate 1 is provided with a chute 5, the bottom of the moving plate 3 is provided with a slider 4 cooperating with the chute 5, the moving plate 3 is slidably installed on the base plate 1; the screw rod 6 is arranged at both ends of the base plate 1;

[0028] The two fixed plates 2 are respectively arranged on the two ends of the base plate 1, and the two ends of the moving plate 3 lean against the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com