Patents

Literature

44results about How to "Movement does not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

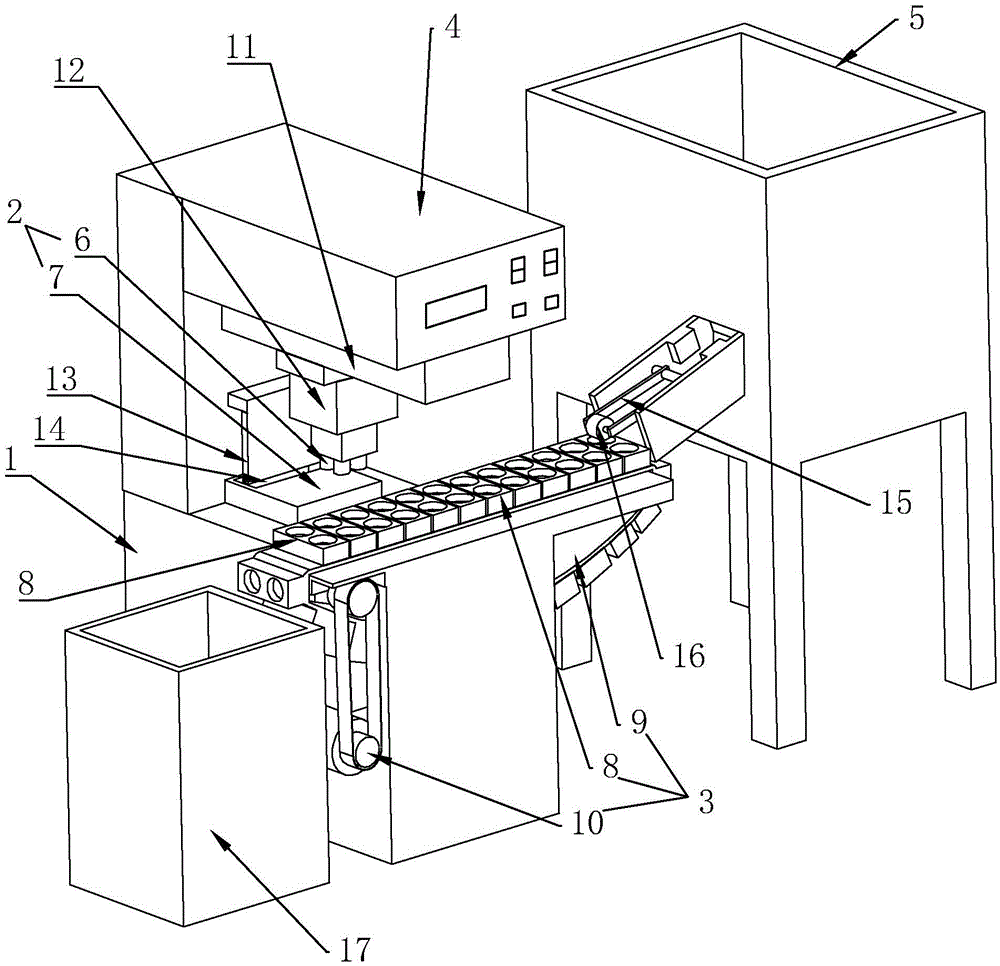

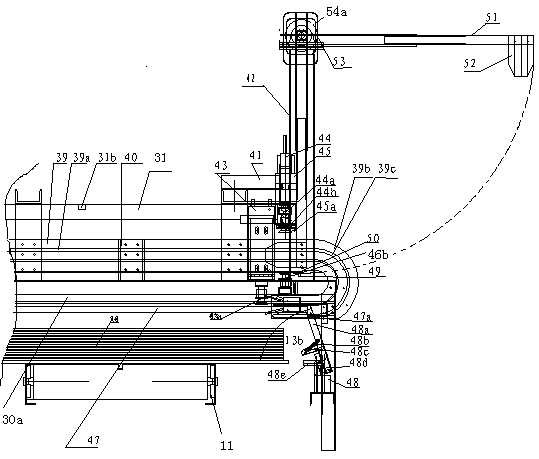

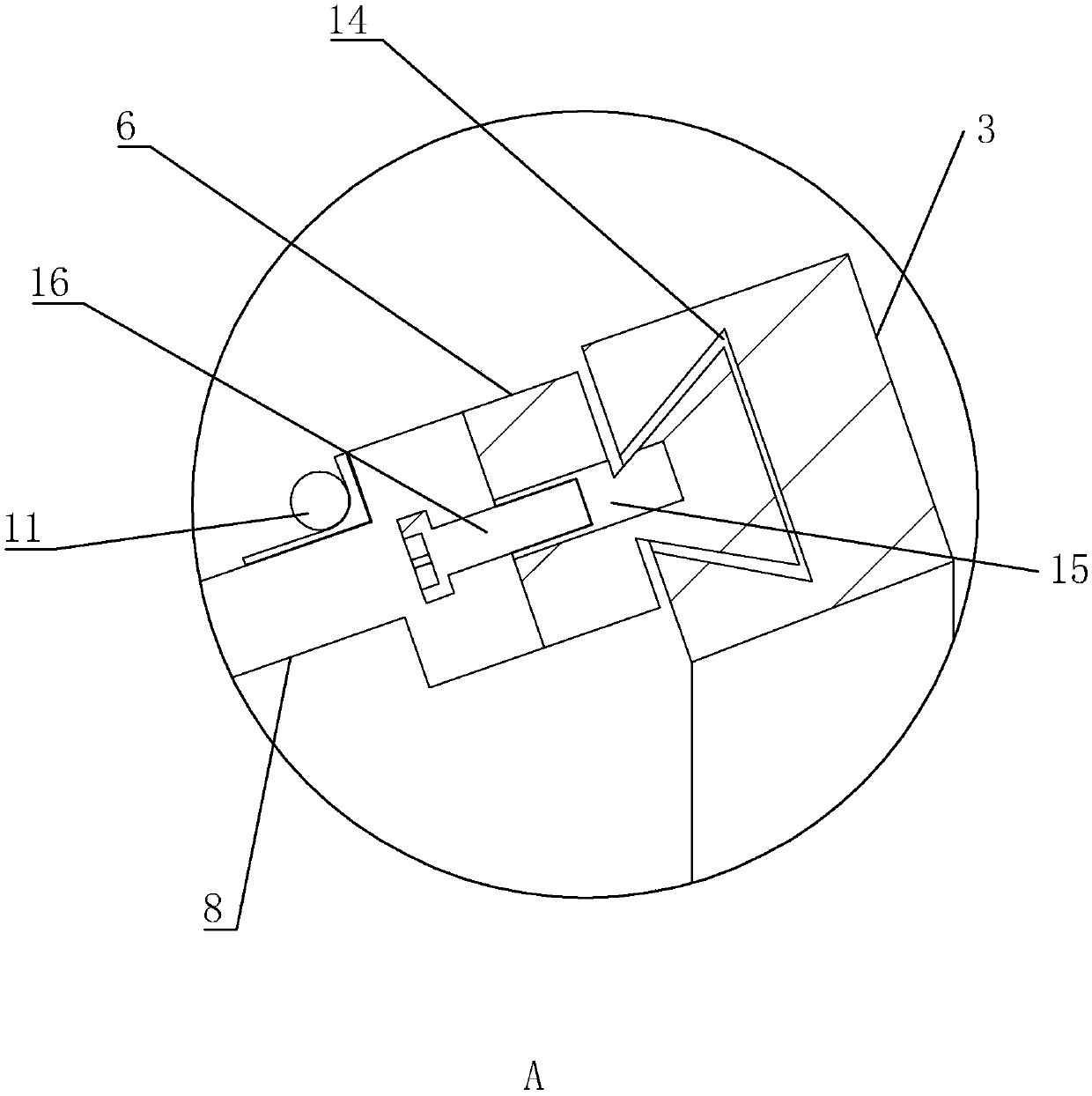

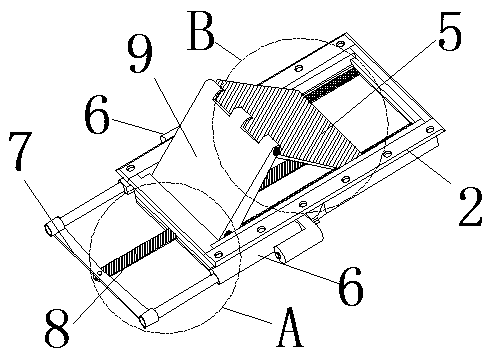

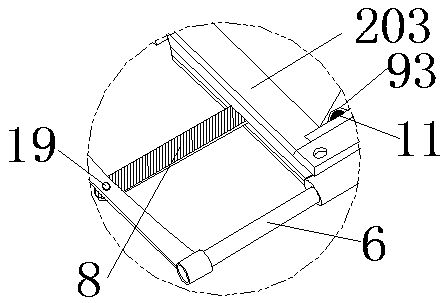

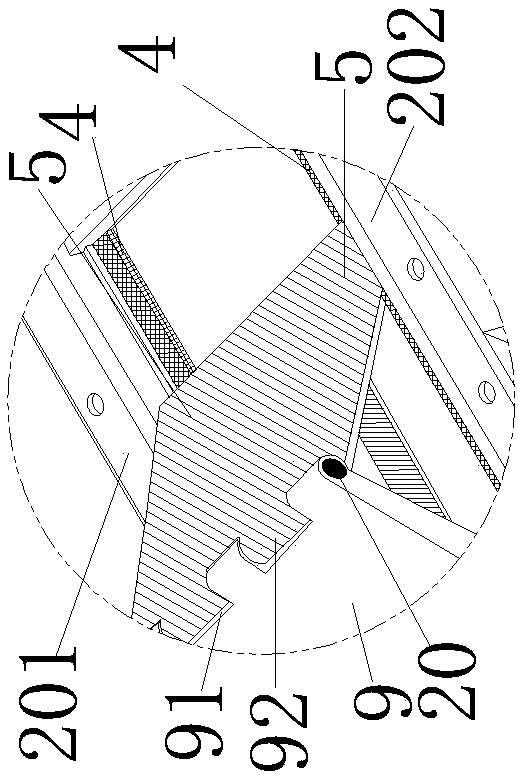

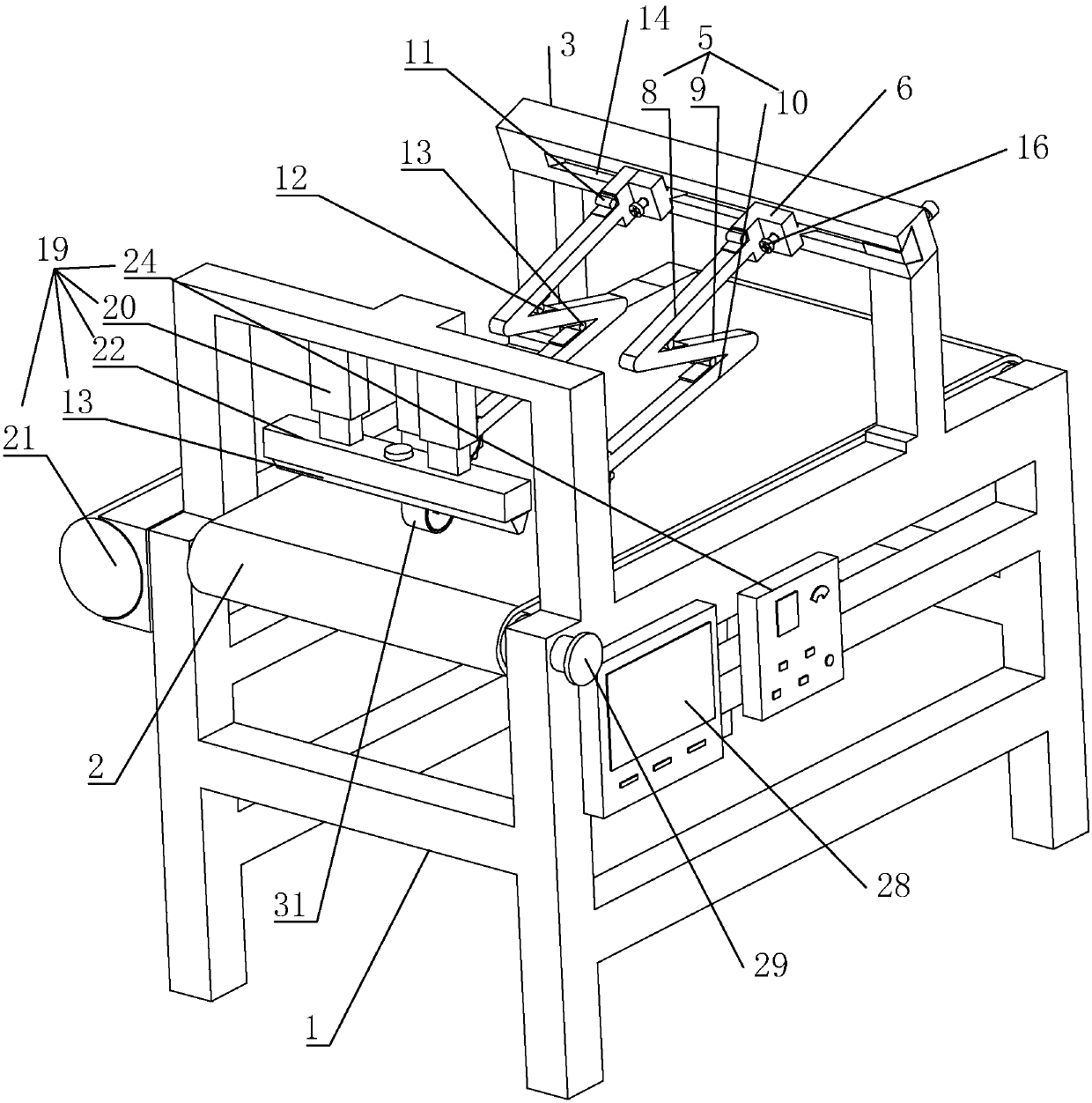

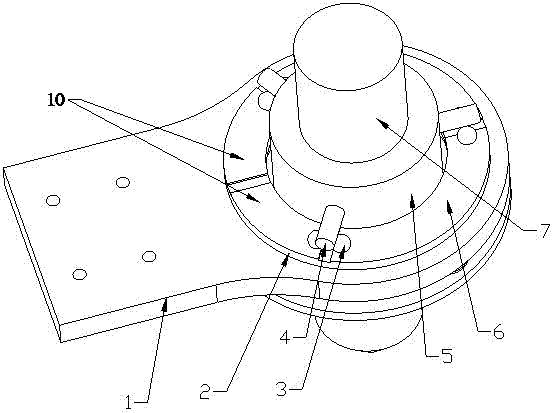

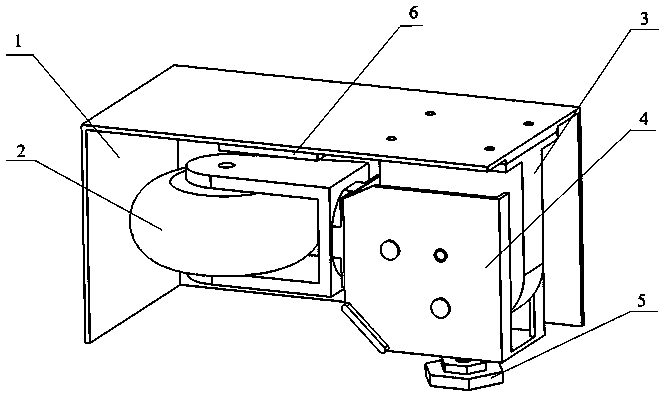

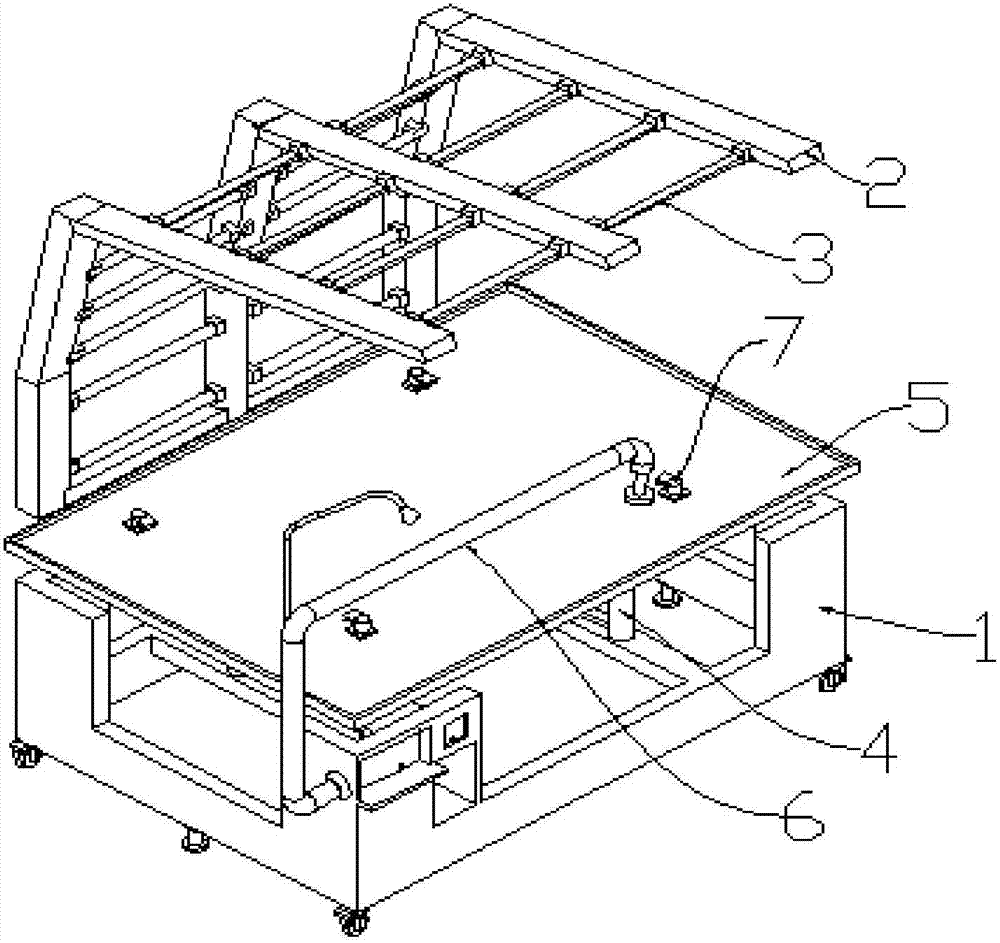

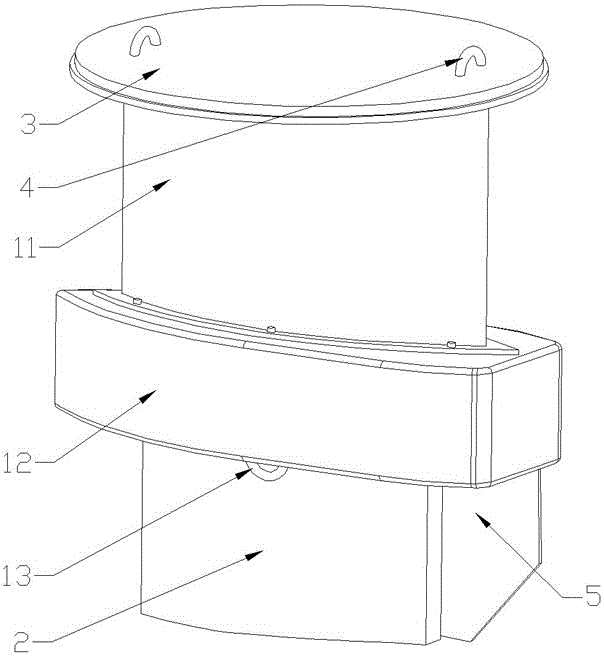

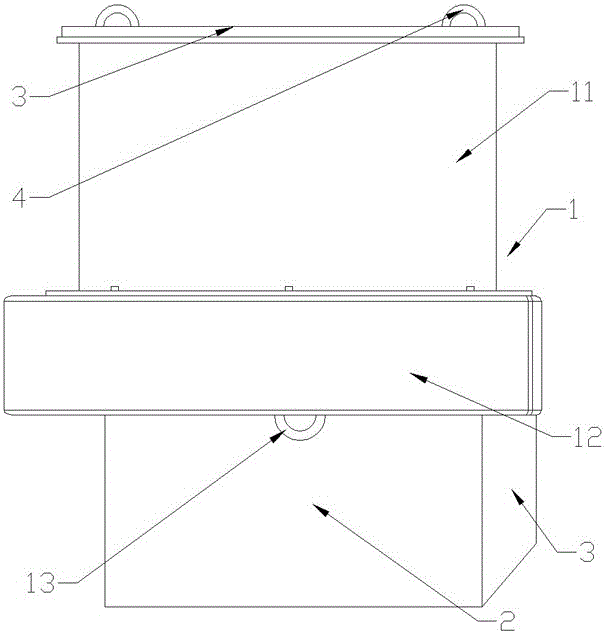

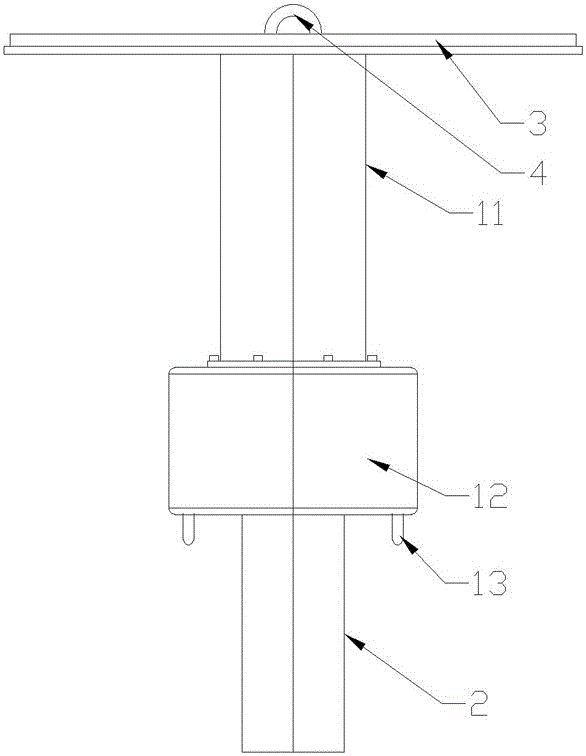

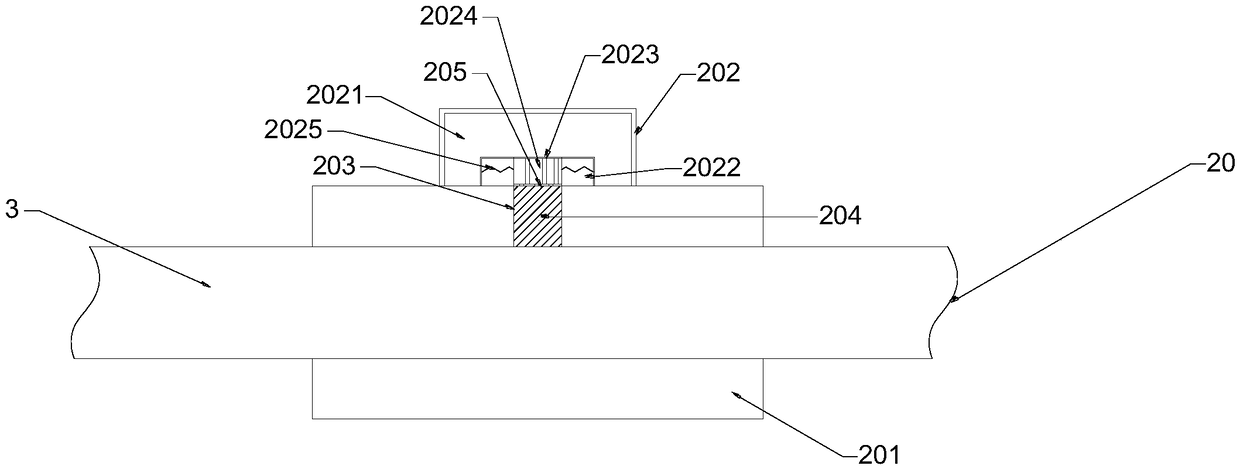

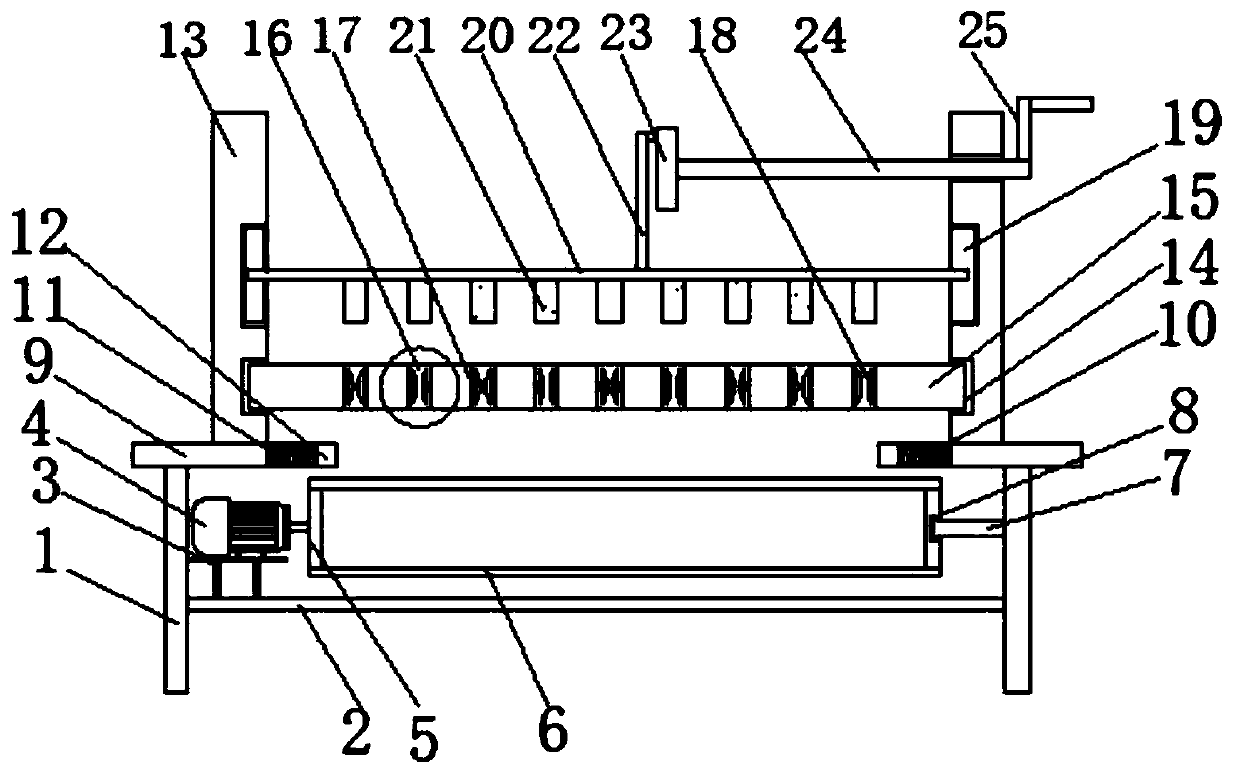

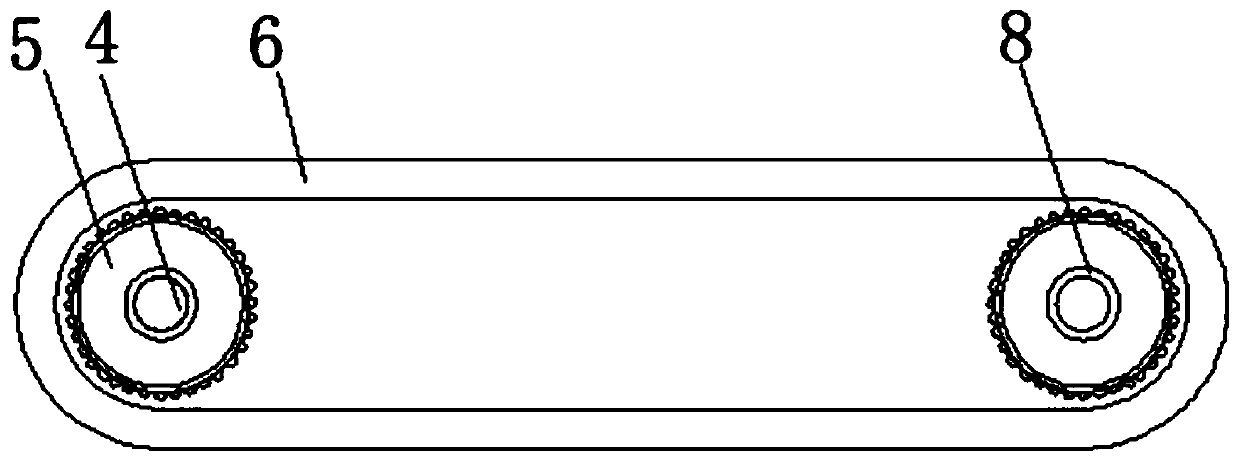

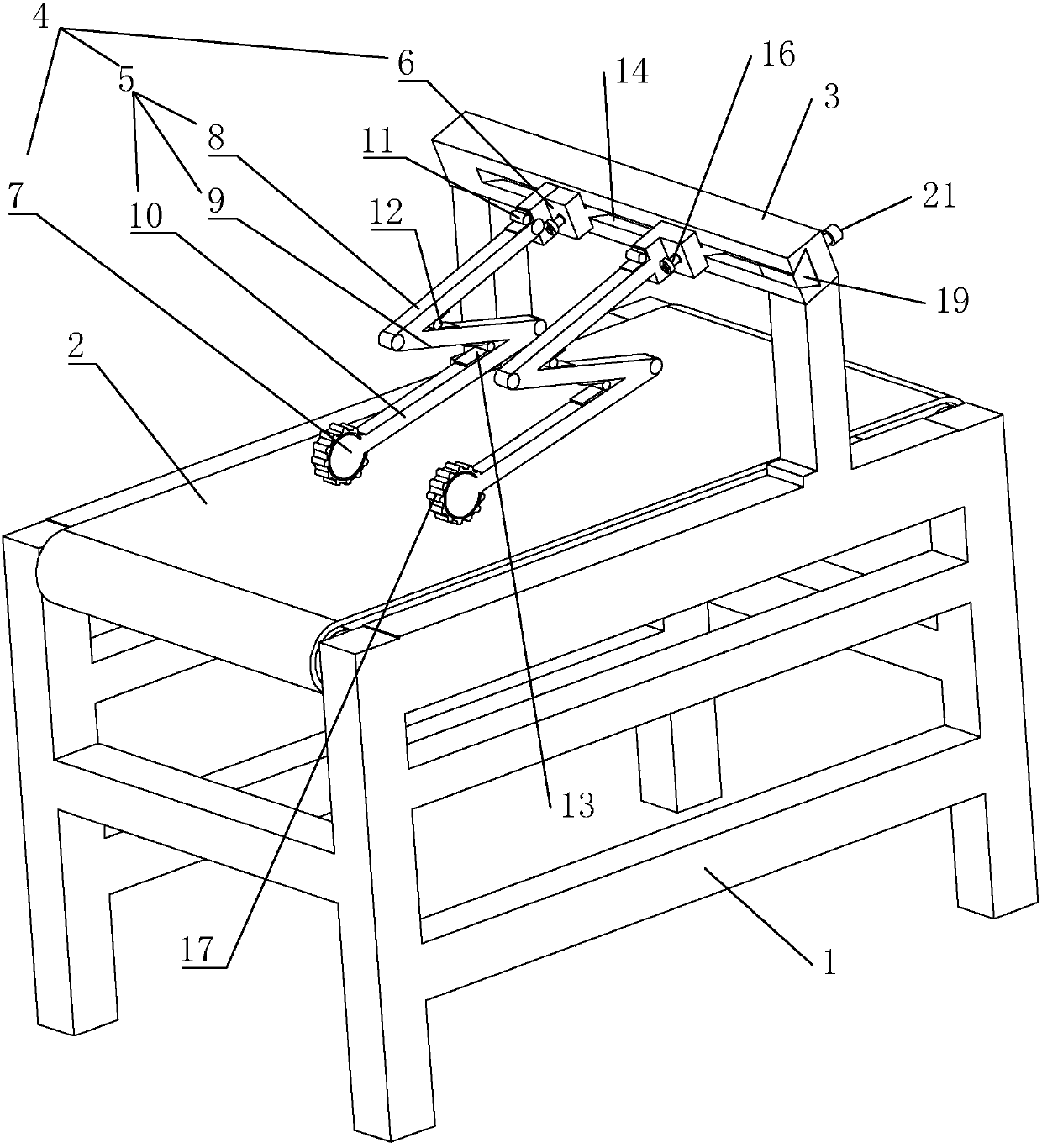

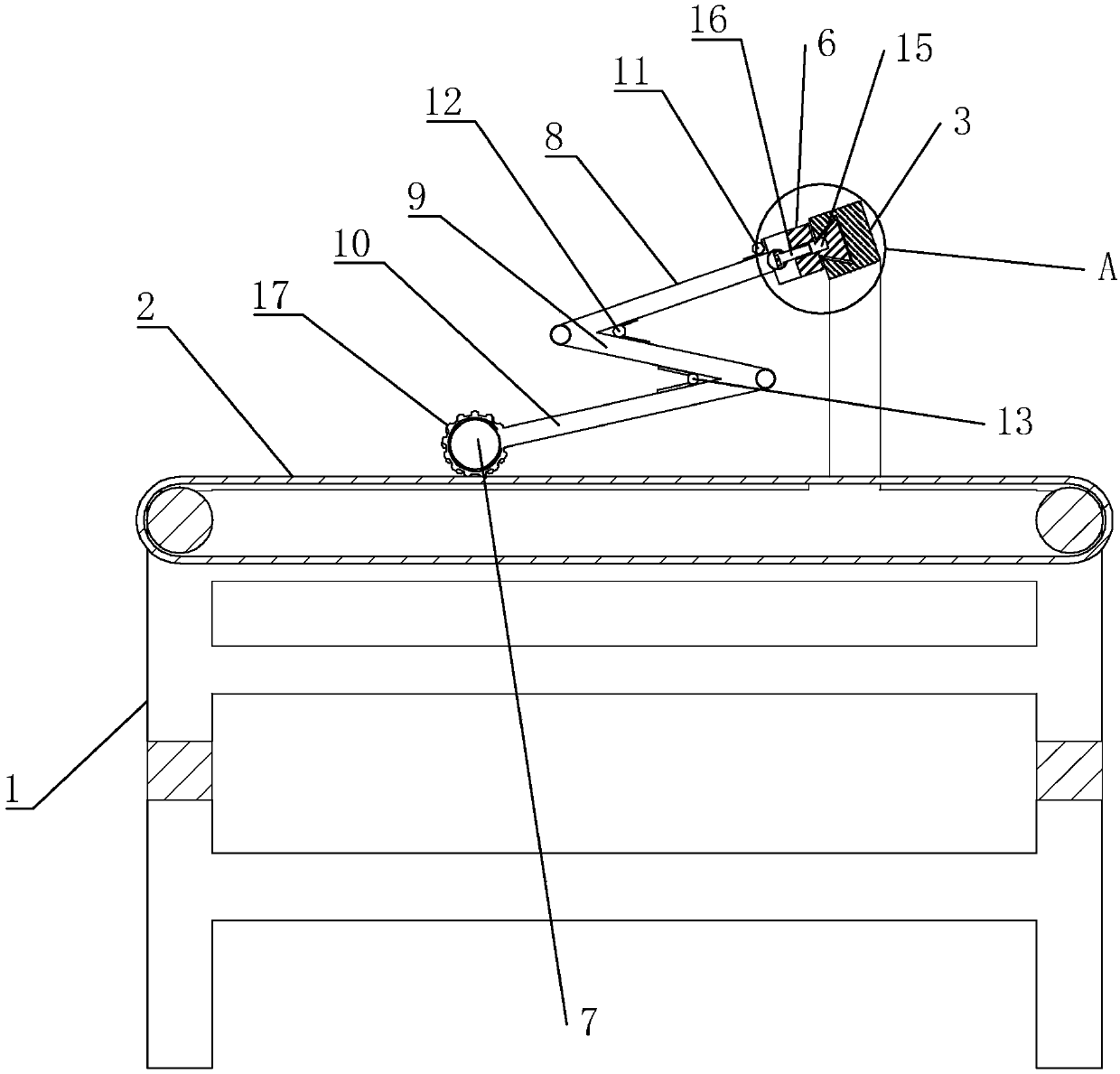

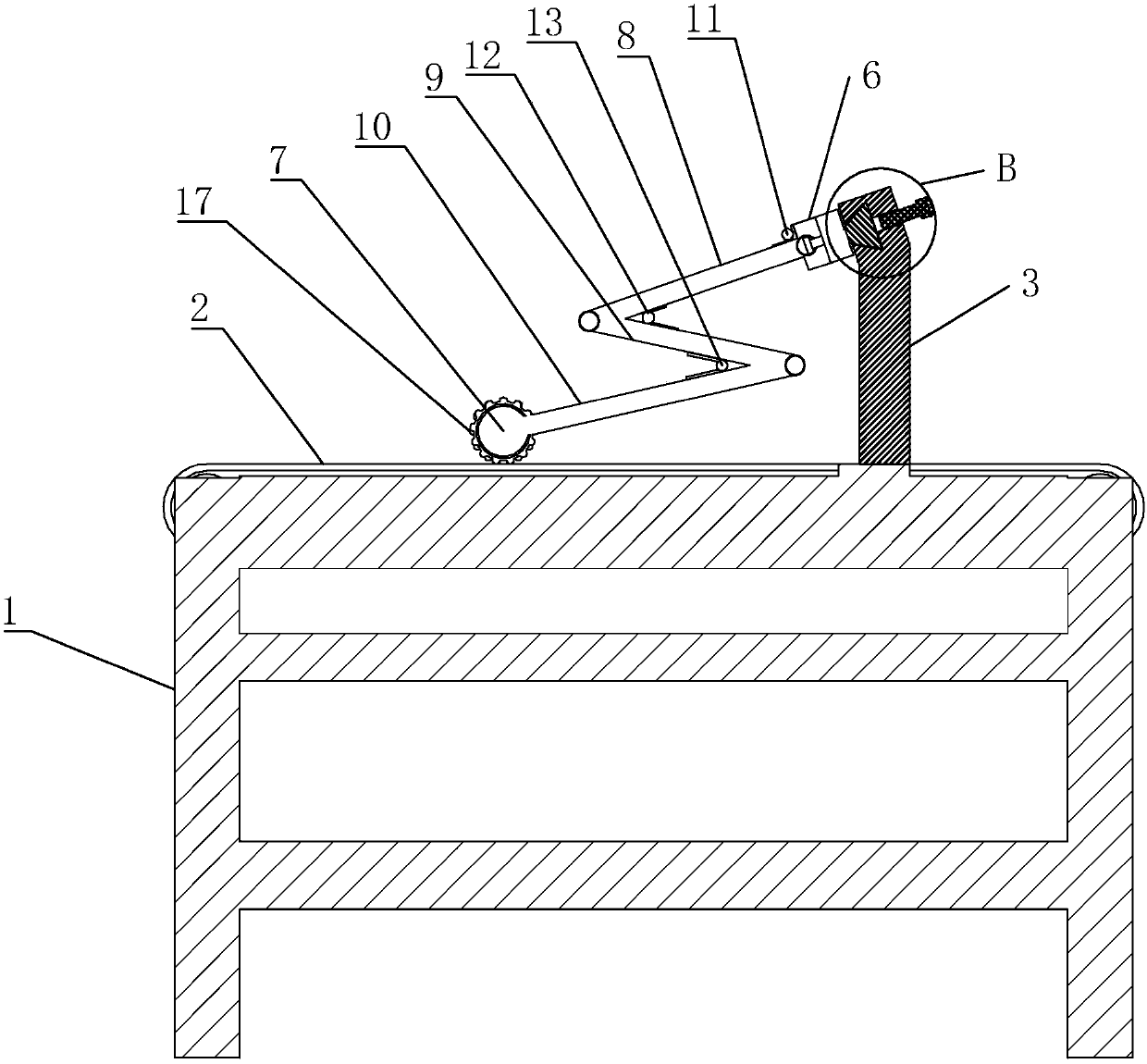

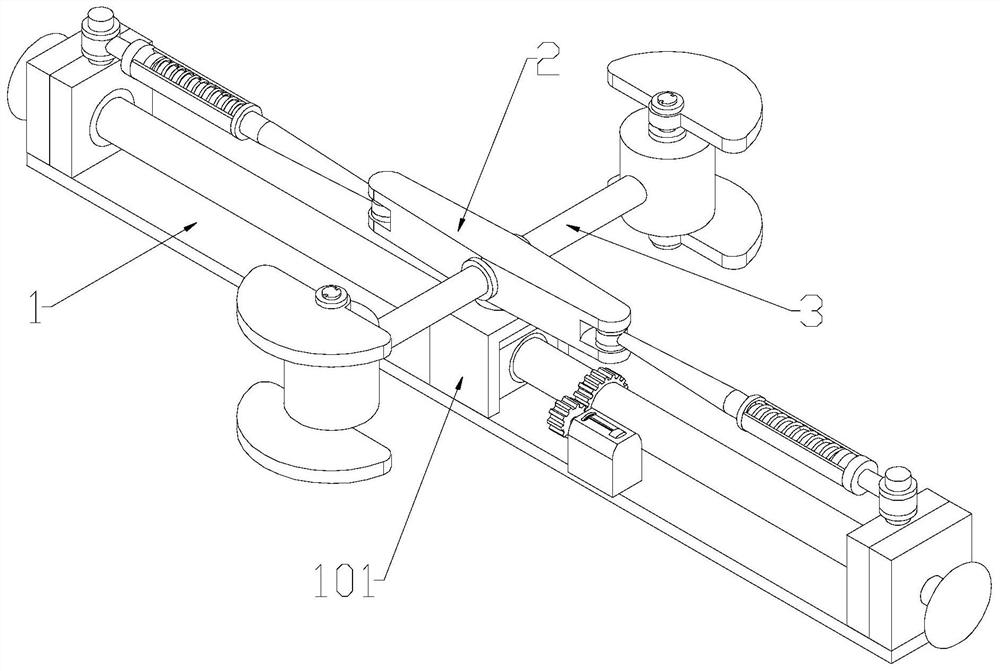

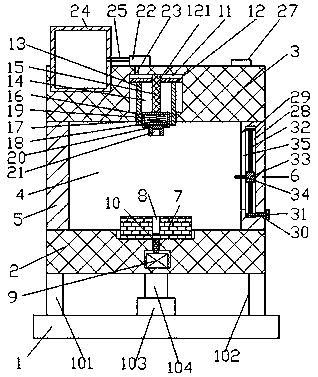

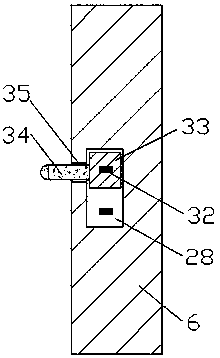

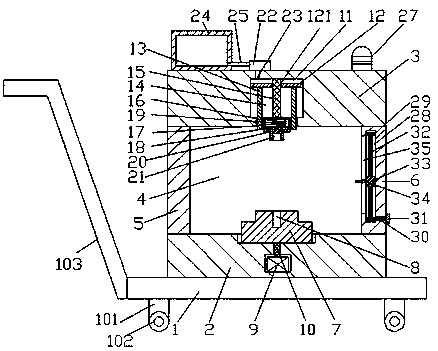

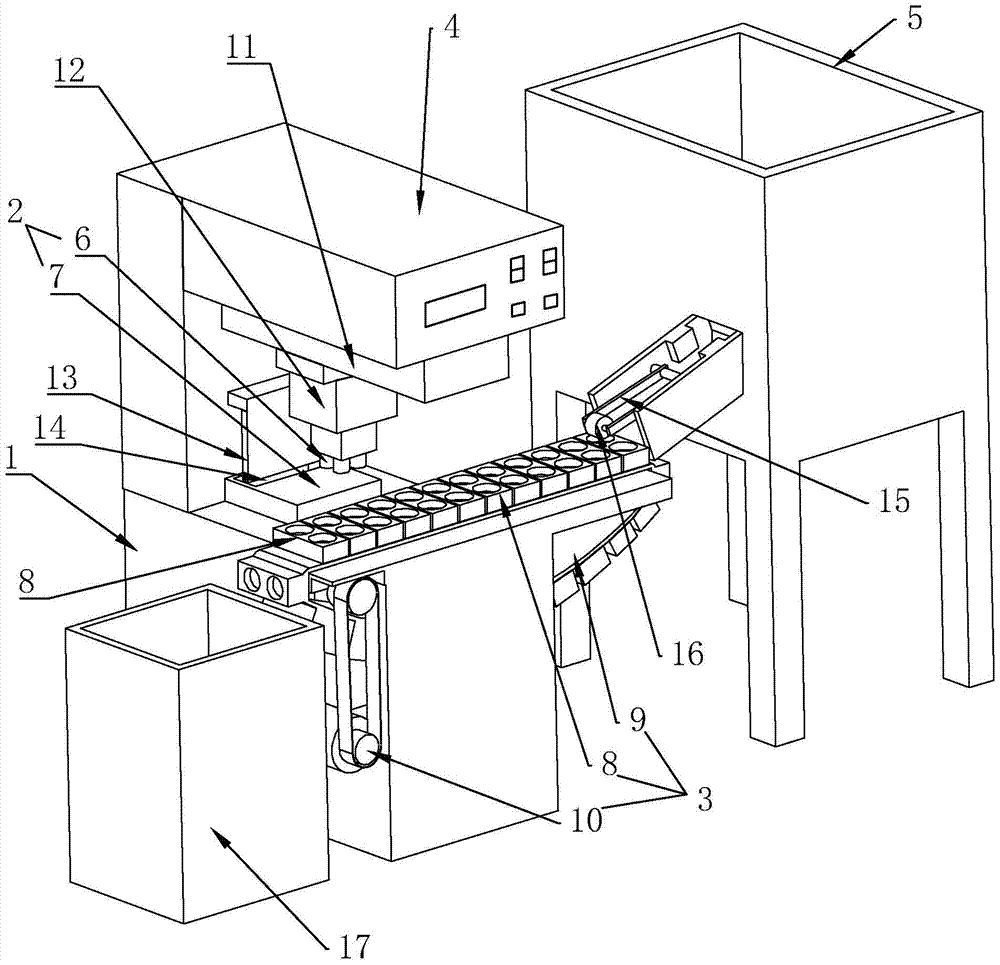

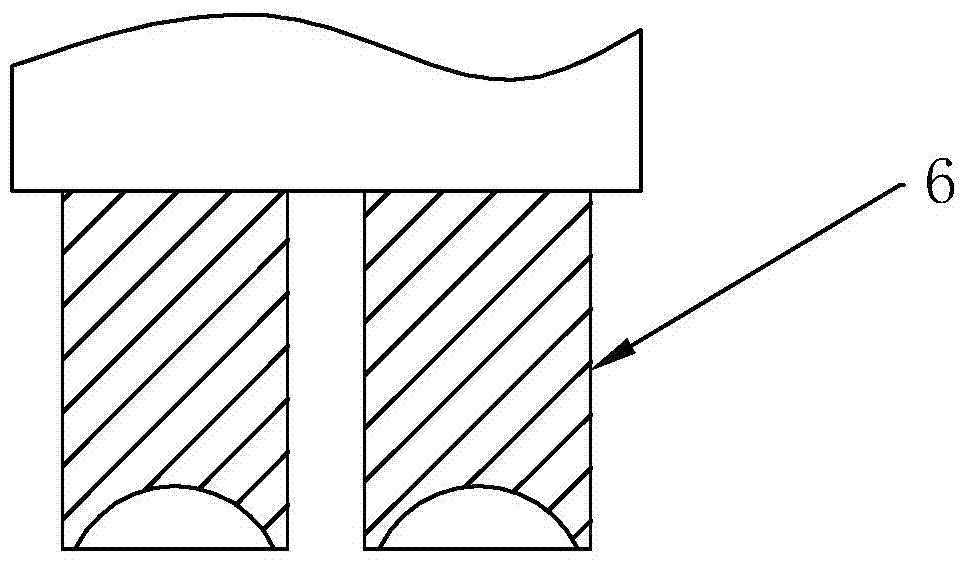

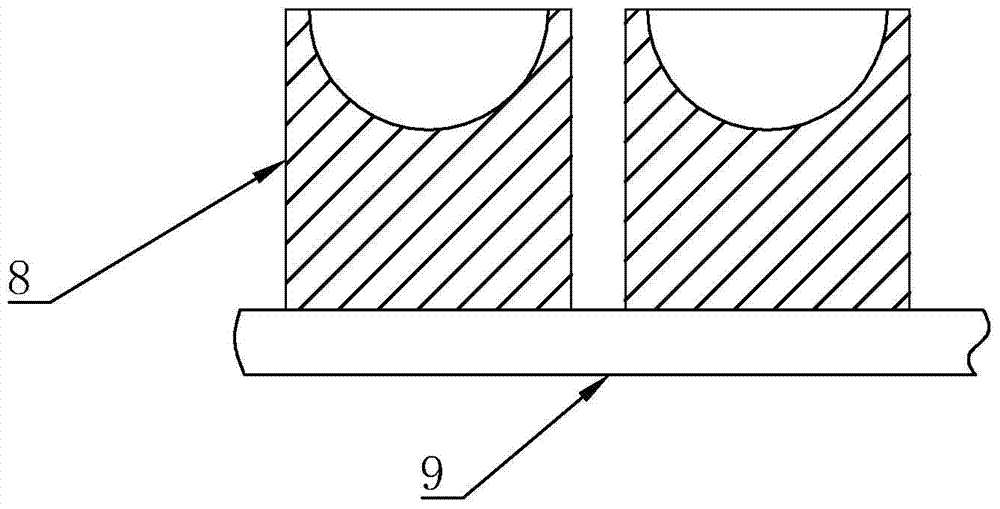

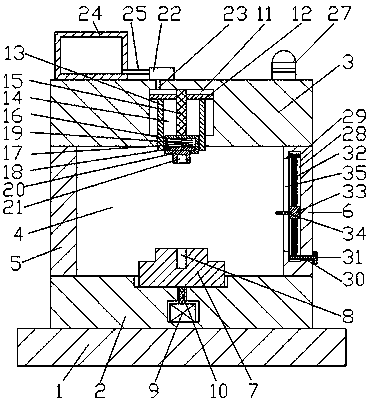

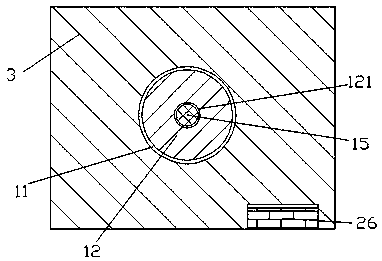

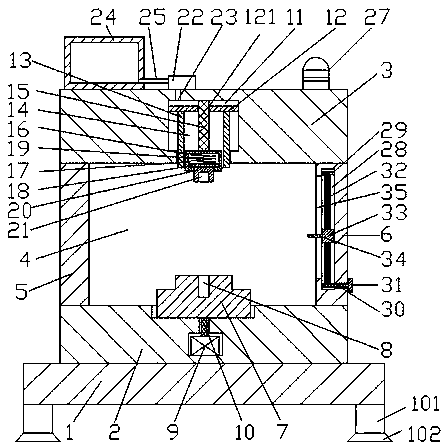

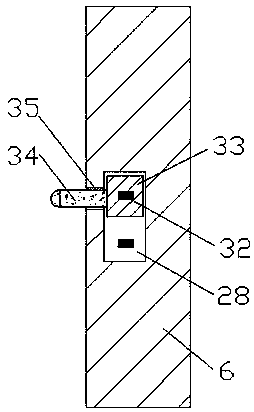

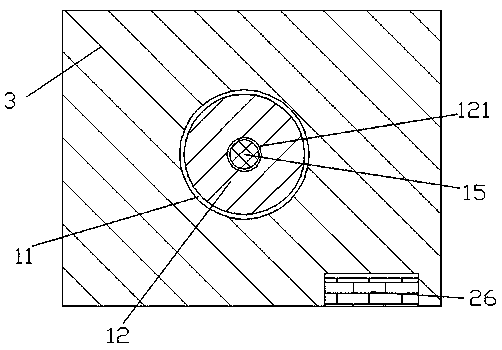

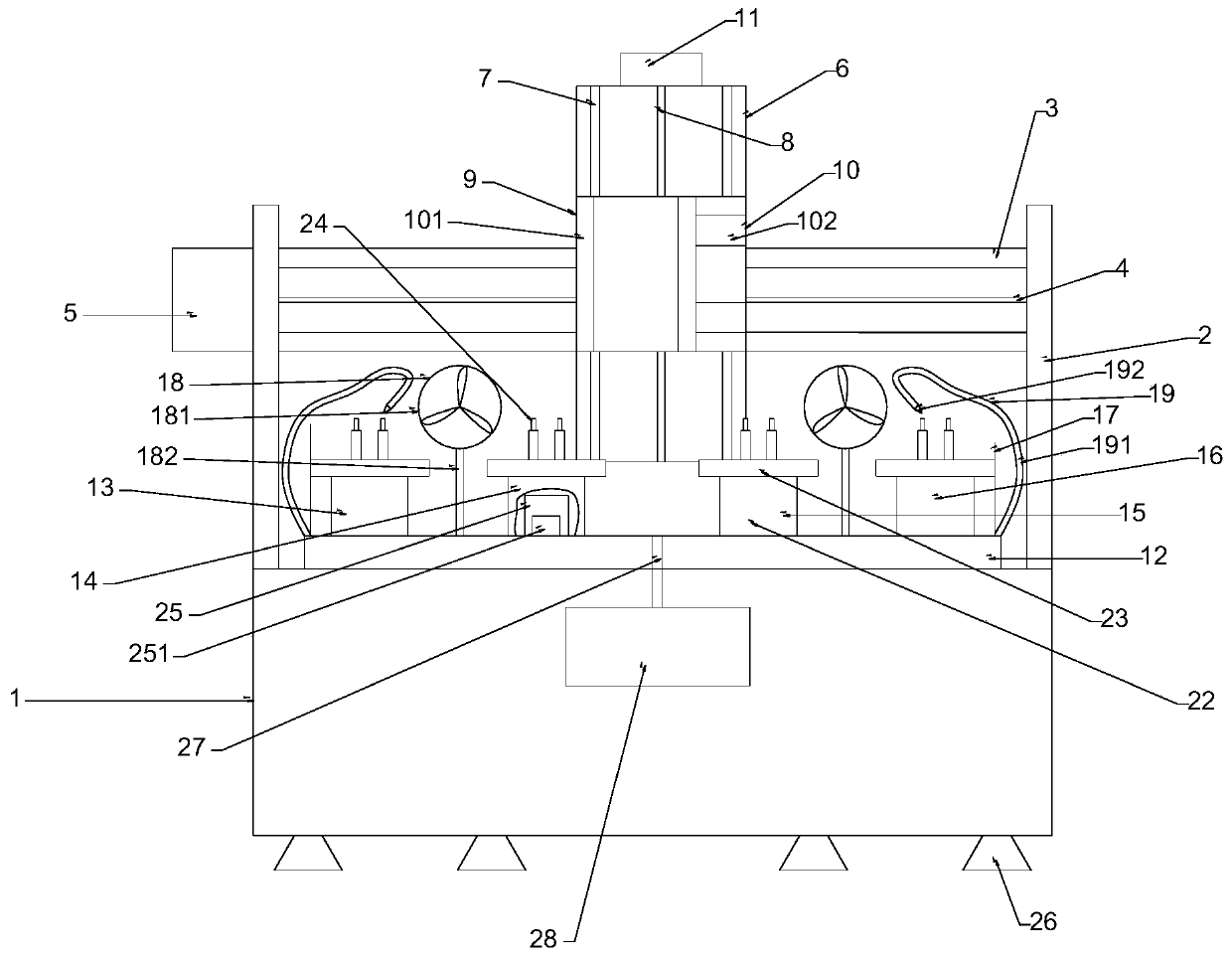

Trademark printing machine used for table tennis ball body

InactiveCN105459616AEasy to moveMobile stability ping pong does not occurTypewritersOther printing apparatusTrademarkEngineering

The invention discloses a trademark printing machine used for a table tennis ball body. According to the technical scheme, the trademark printing machine comprises a machine body, a printing device arranged at the upper end of the machine body, a feeding device arranged at the lower end of the machine body and matched with the printing device, a control box arranged on the machine body and used for controlling the printing device and the feeding device, a storage box arranged on the machine body and matched with the feeding device, and a collecting box arranged on the machine body. The trademark printing machine used for the table tennis ball body can be used for automatically printing a trademark on the table tennis ball body, the table tennis ball body can be automatically unloaded and collected, labor cost is saved, and production efficiency is improved.

Owner:浙江曙光体育用品有限公司

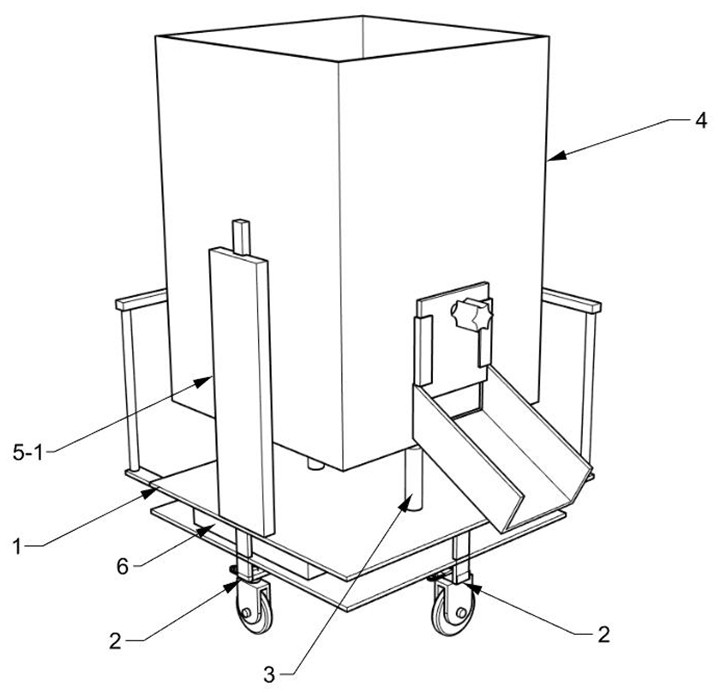

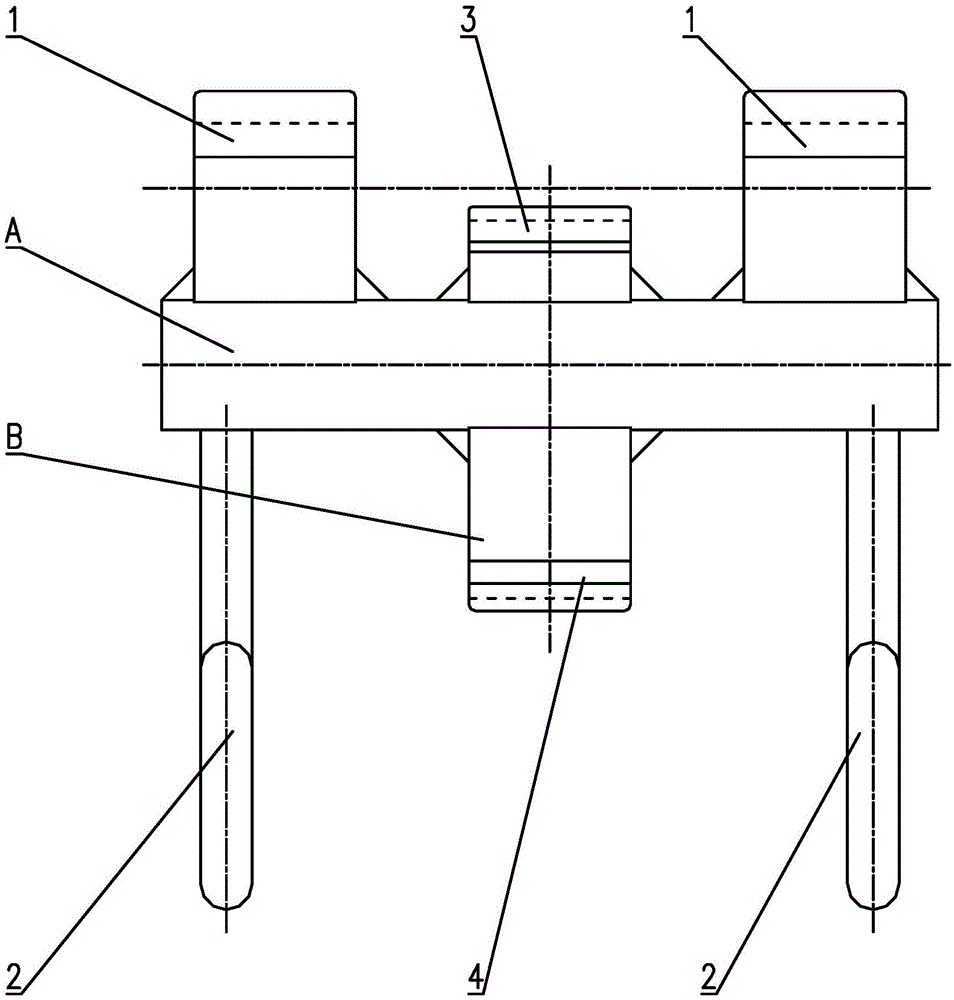

Four-direction displacement geotechnical bridge handrail concrete pouring device

ActiveCN111851290ASolving Difficult-to-Pour ProblemsImprove integrityBridge structural detailsBridge erection/assemblyRack and pinionHandrail

The invention discloses a four-direction displacement geotechnical bridge handrail concrete pouring device. The geotechnical bridge handrail concrete pouring device comprises a chassis, wheel systems,a hydraulic rod and a storage box. Two sets of wheel systems are installed on the lower surface of the chassis and arranged in a crossed mode. The storage box is arranged on the upper surface of thechassis in an up-down sliding mode, the hydraulic rod is arranged between the storage box and the chassis, and the hydraulic rod pushes the storage box to move up and down; L-shaped push handles are arranged on the adjacent side edges of a bottom frame; each wheel system comprises a wheel bridge, a wheel arm, a roller, a steering rod, a connecting rod and a rack; and the wheel arms are rotatably installed below the two ends of the wheel bridges, and the rollers are installed on the wheel arms. The device is specially used for pouring construction of a bridge handrail, prepared concrete can berapidly poured into a handrail mold of a bridge through the device, and meanwhile the height of a discharging opening can be adjusted according to the height of the handrail so as to achieve adaptation. According to wheel layout, steering can be well controlled, and rapid and accurate positioning to a target area can be achieved.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY +1

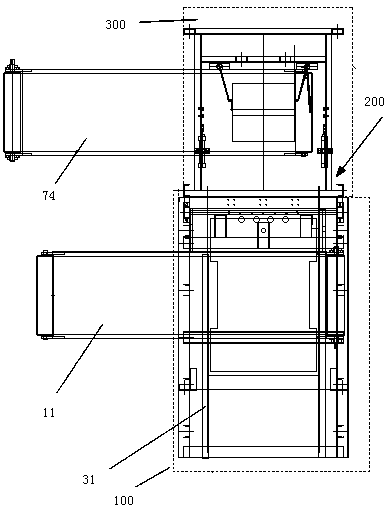

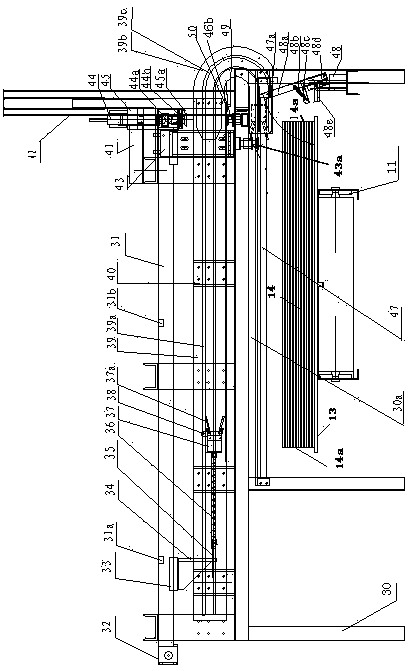

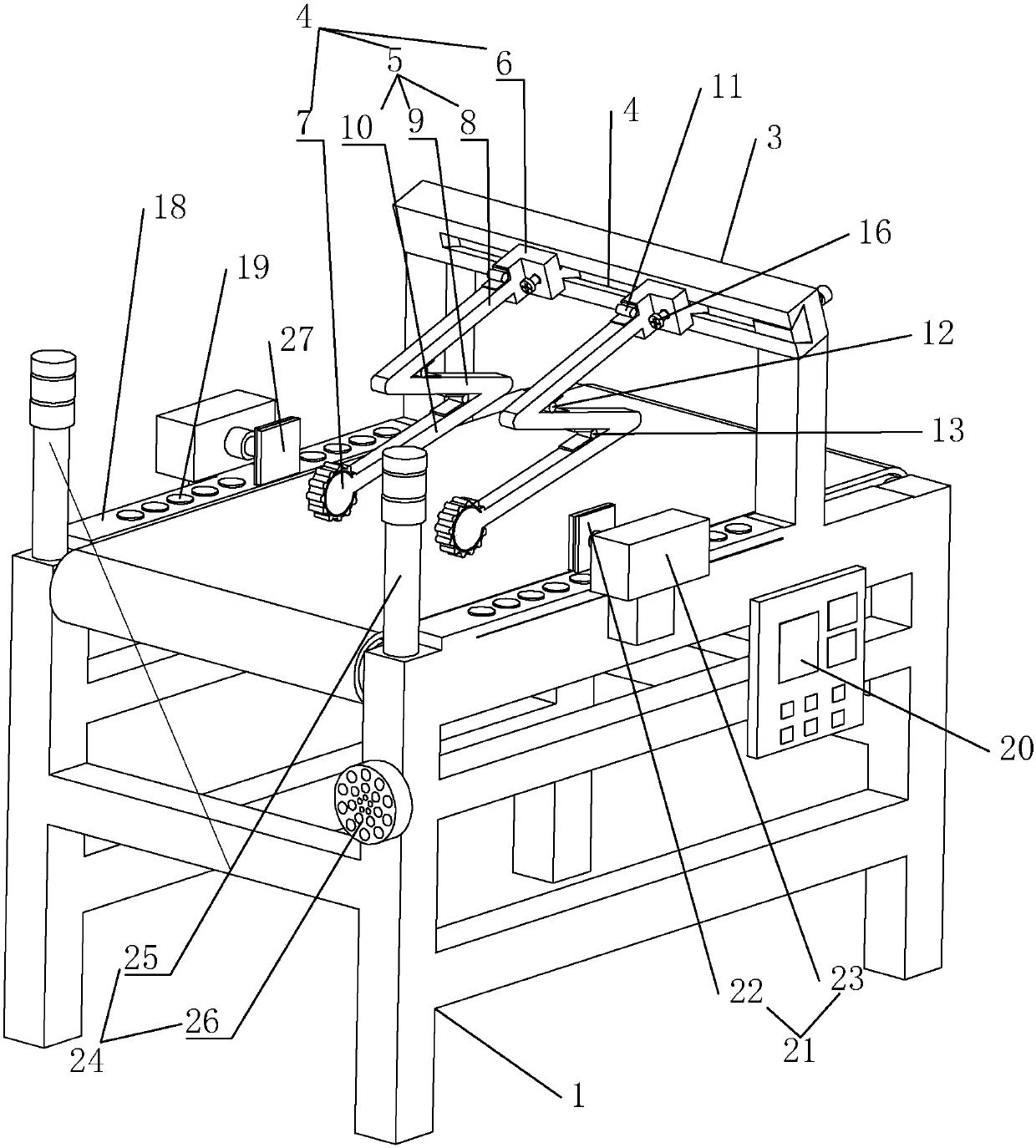

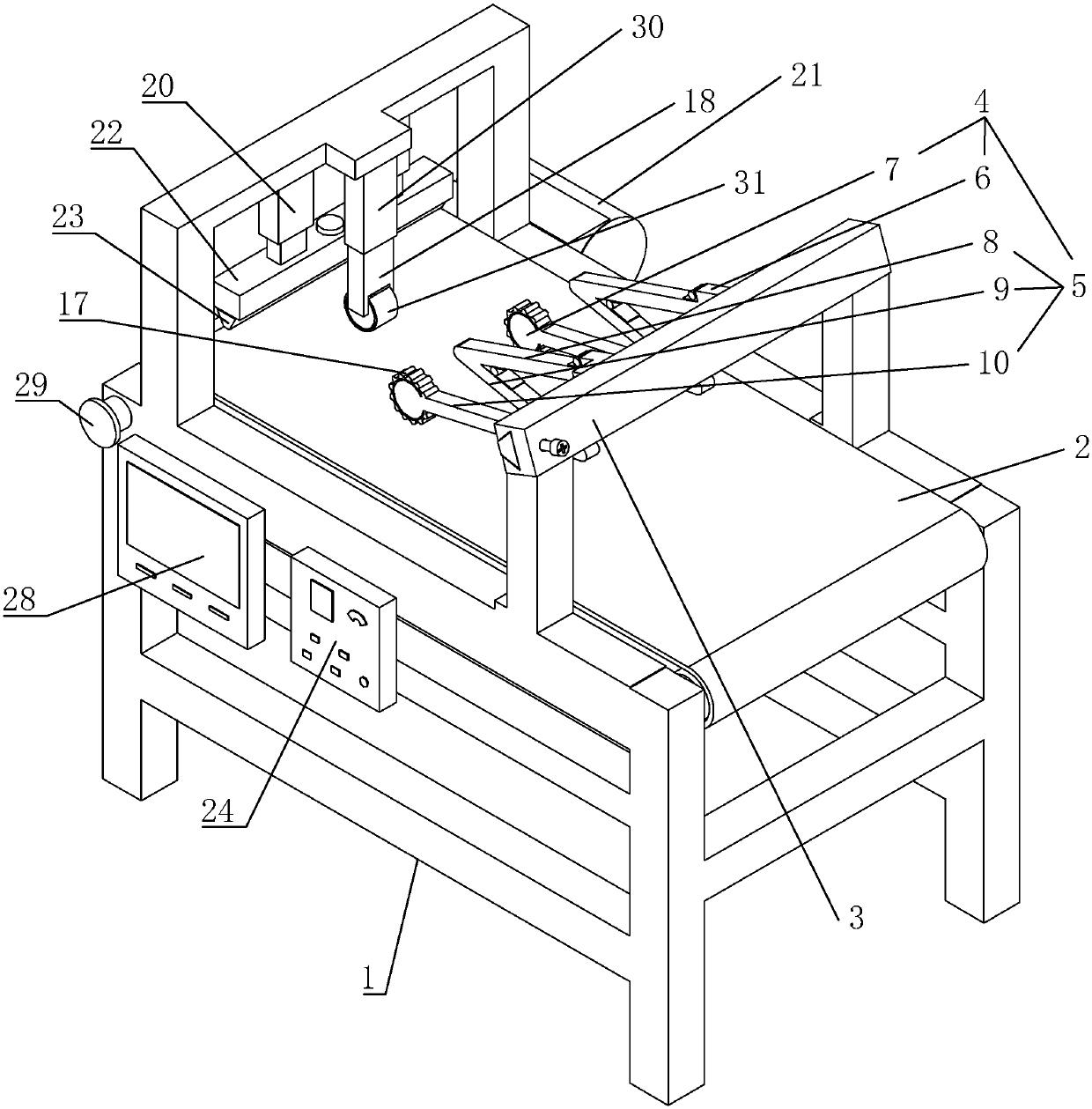

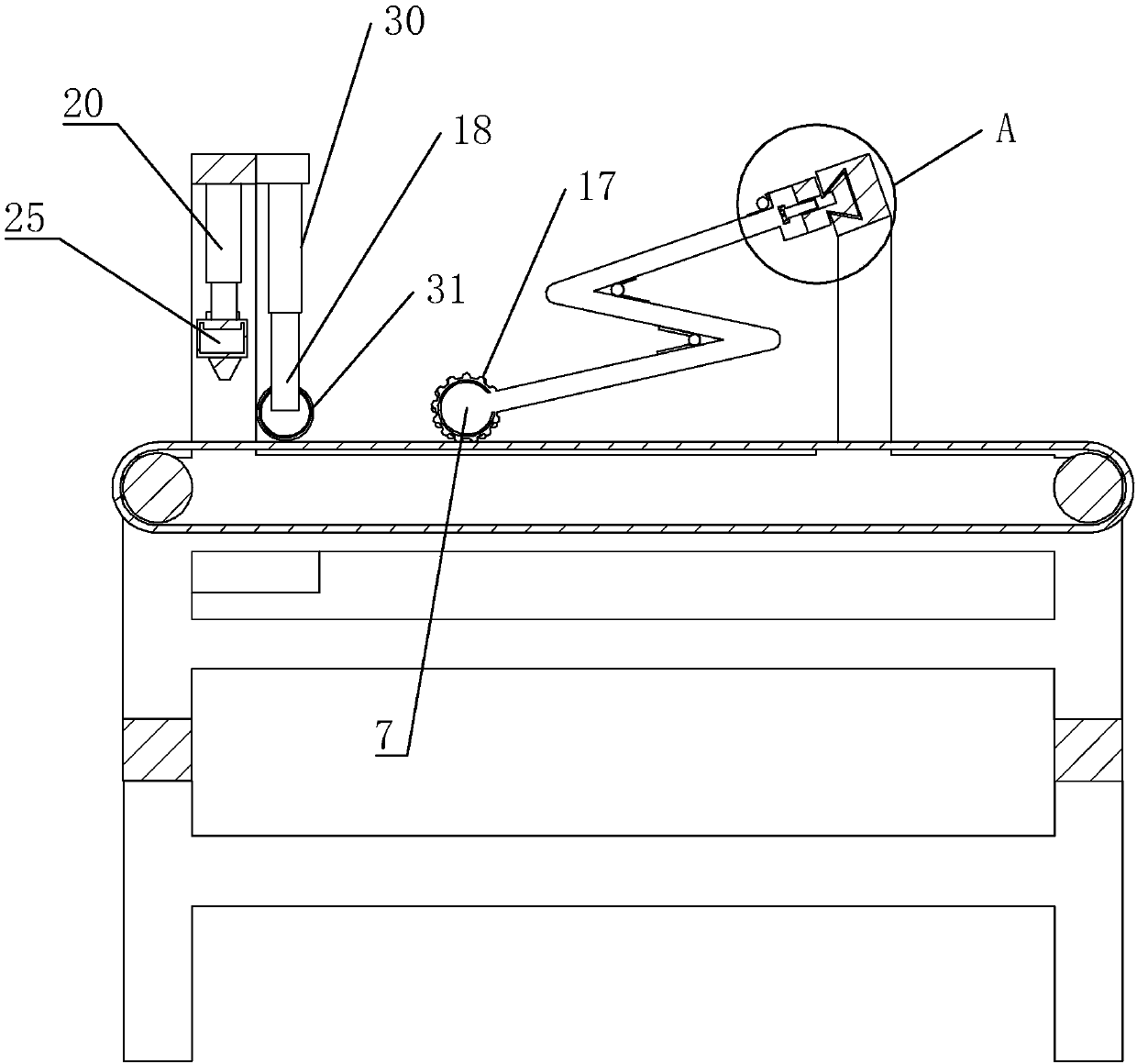

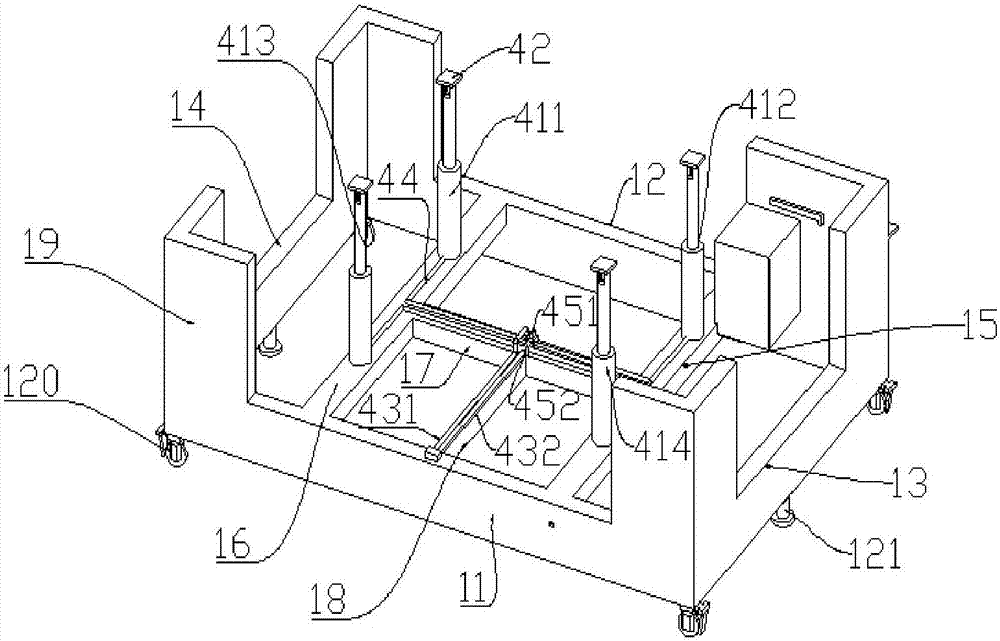

Bag taking and expanding equipment for packaging bags and bag taking and expanding method thereof

PendingCN111439431AShorten the lengthReduce in quantitySolid materialPackaging automatic controlMechanical engineeringElectrical and Electronics engineering

The invention discloses bag taking and expanding equipment for packaging bags and a bag taking and expanding method thereof, and belongs to the field of packaging equipment. The bag taking and expanding equipment comprises a bag taking device, a bag expanding device and a bag opening fixing device; the bag taking device comprises a platform, a transmission belt end point in the vertical directionis arranged below the platform, a product transmission belt is arranged behind the bag taking device, and a discharging opening and the bag opening fixing device are arranged above the product transmission belt; the bag taking device comprises a bag clamping push-pull mechanism, a bag pressing mechanism, a bag dividing horizontal bar, a bag taking device mechanism and a pressing bar mechanism; thebag expanding device comprises a bag expanding mechanism and a bag expanding rotating mechanism; and the bag expanding fixing device comprises a bag opening clamping plate mechanism, a bag opening tensioning mechanism and a packaging bag baffle mechanism. The stacked packaging bags can be separated accurately, the bag falling phenomenon in the bag taking process can be prevented, the displacementphenomenon of the packaging bags on the lower layer can be avoided, wrinkles, folding corners and the like of the packaging bags can be flattened, bag openings are parallel to the rear end of a bottom plate while the packaging bags are flattened, the failure rate can be reduced, the energy consumption can be reduced, and the production efficiency can be improved.

Owner:吕彦民

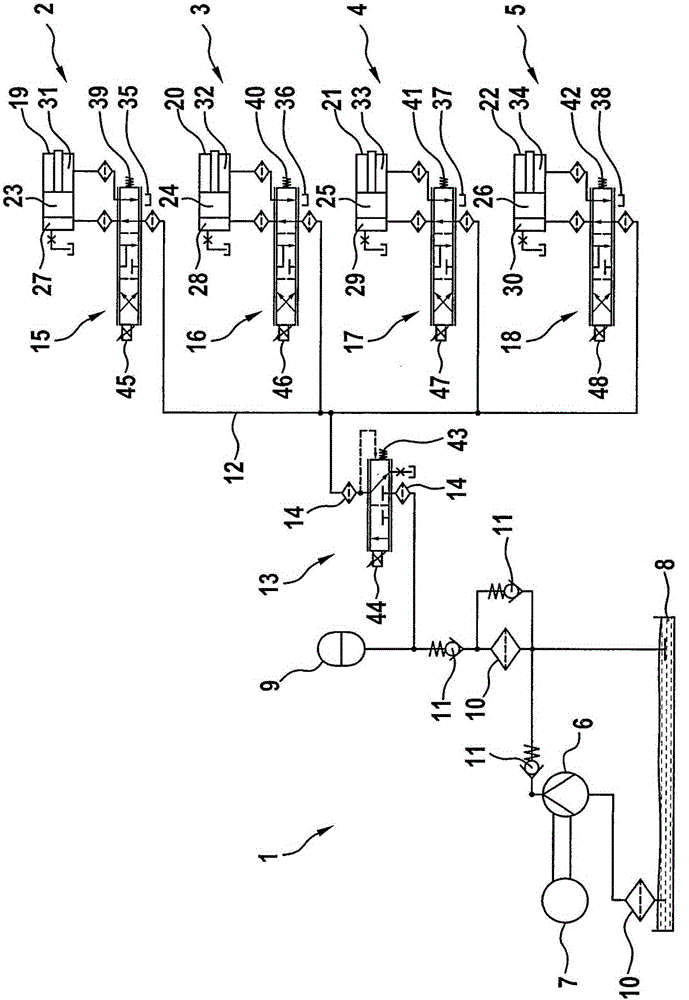

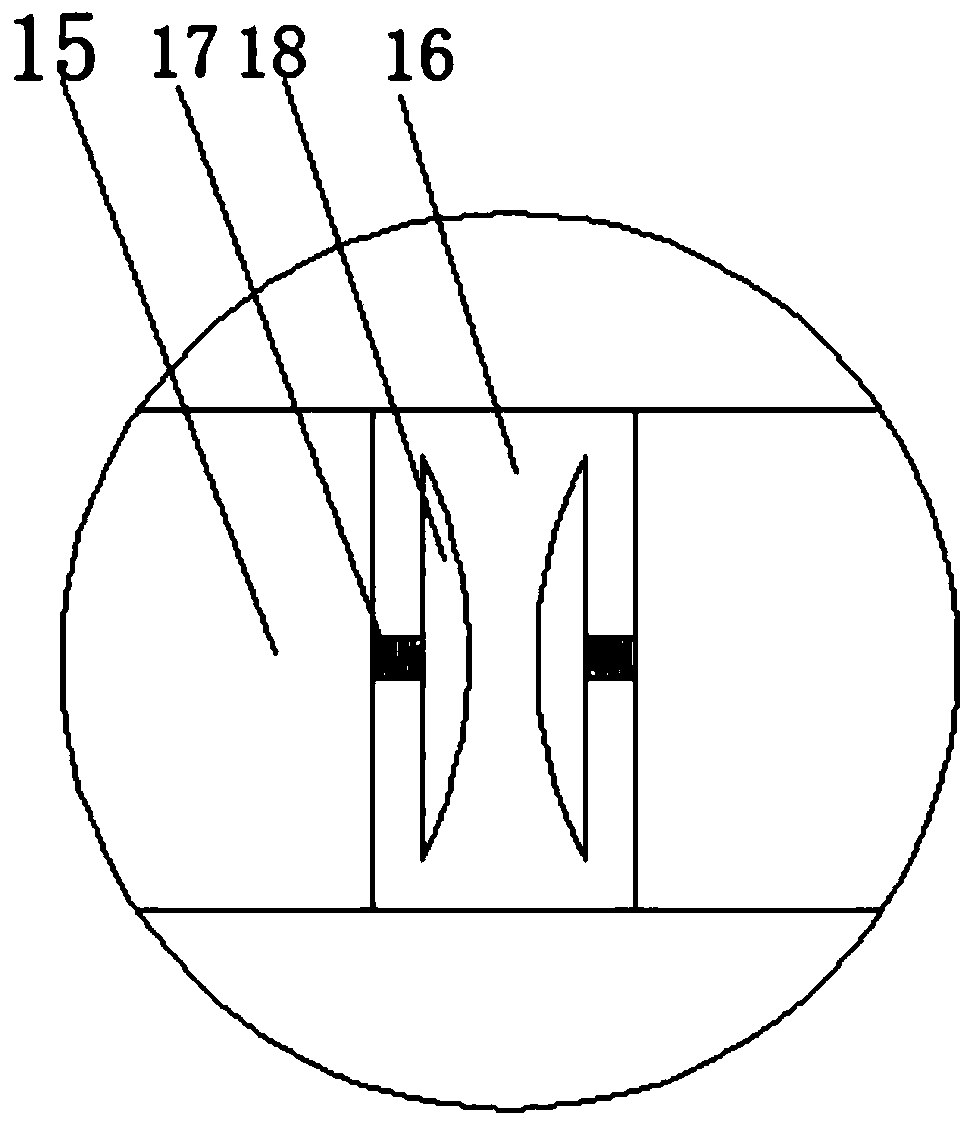

Method for operating a transmission device and corresponding transmission device

The invention relates to a method for operating a transmission device (1), in particular a double-clutch transmission device, the transmission device (1) comprising a plurality of gear selectors (2, 3, 4, 5) each having a gear selector valve (15, 16, 17, 18), and a gear selector piston (23, 24, 25, 26) which is operatively connected to a selector fork of the transmission device (1), is arranged in a gear selector cylinder (19, 20, 21, 22) and divides the latter into a first pressure chamber (27, 28, 29, 30) and a second pressure chamber (31, 32, 30 36). In a first shifting position of the gear selector valve (15, 16, 17, 18), the first pressure chamber (27, 28, 29, 30) has a flow connection to a common feed line (12), in a second shifting position, the second pressure chamber (31, 32, 33, 34) has a flow connection to a common feed line (12), and in a neutral position, none of the pressure chambers (27, 31; 28, 32; 29, 33; 30, 34) has a flow connection to a common feed line; and a flow connection of the feed line (12) to a common pressure source (6) is enabled in a first operating position of the shifting valve (13) and is interrupted in a second operating position of the shifting valve (13). Here, according to the invention, to achieve a change from a standby operating mode into a power saving operating mode, a pressure test is carried out, in which the gear selector valves (15, 16, 17, 18) of the gear selectors (2, 3, 4, 5) for setting the neutral position and the shifting valve (13) for setting the second operating position are activated, and then the gear selector valve (15, 16, 17, 18) of at least one of the gear selectors (2, 3, 4, 5) for setting one of the shifting positions is activated.

Owner:AUDI AG

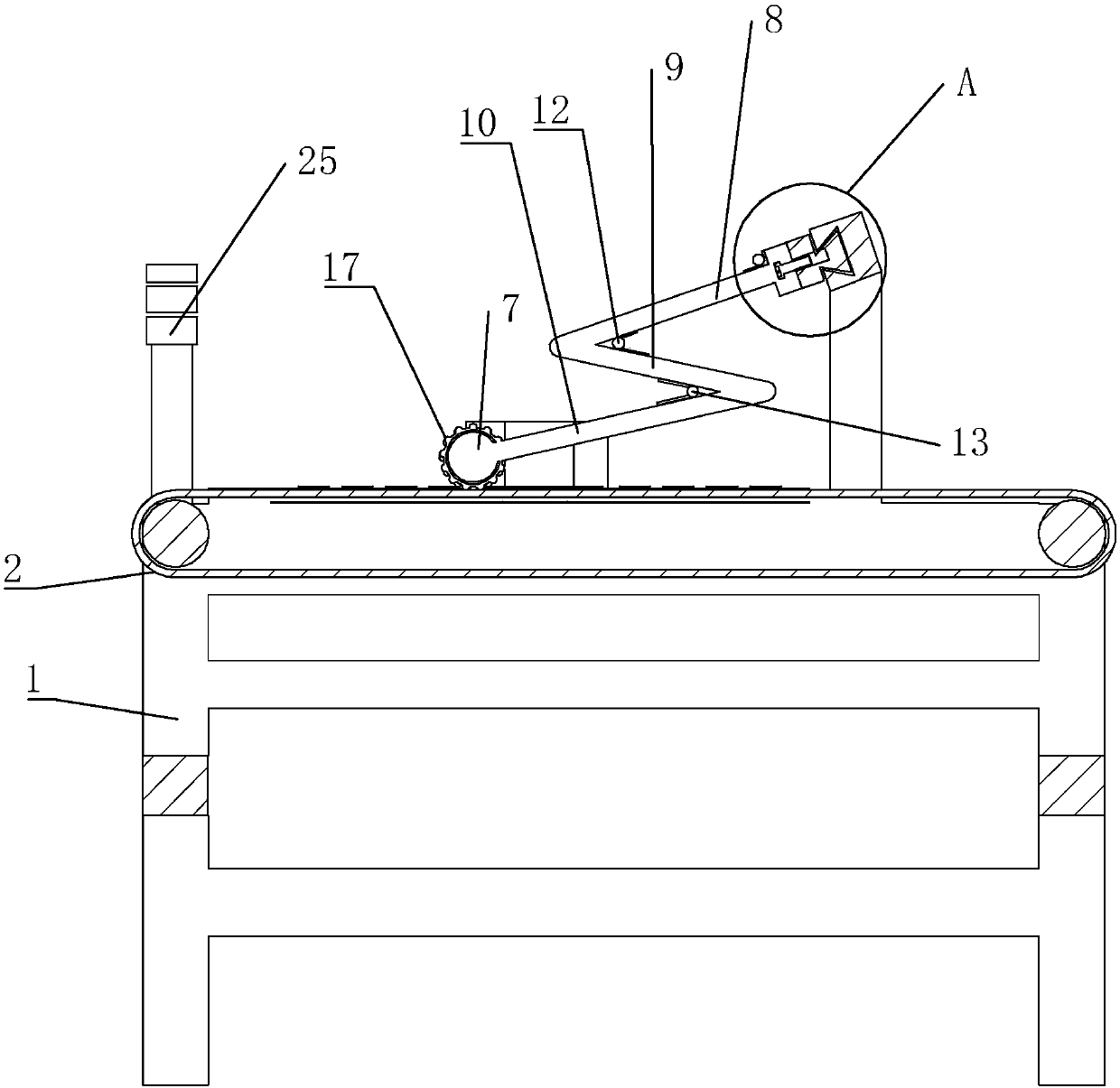

Paperboard conveyor for preventing paperboards from falling and use method thereof

The invention discloses a paperboard conveyor for preventing paperboards from falling. The technical scheme is characterized in that the paperboard conveyor comprises a rack and a conveying belt arranged on the rack, wherein a support located on the upper side of the conveying belt is arranged on the rack, an abut-pressing device abutting against the surface of the conveying belt is arranged on the support, a sliding groove is formed in the support, the cross section of the sliding groove is wedge-shaped, and one end of a fist compressing rod made of a slide block raw material is slidingly installed in the sliding groove; a strip guiding plate is arranged on the rack, an infrared detector is arranged on the strip guiding plate, a processor is arranged on the rack, and position correction devices for paperboard resetting are arranged on the rack and located on two sides of the conveying belt respectively. The paperboard conveyor for preventing paperboards from falling can abut and presscarton paperboards on the surface of the conveying belt, carton paperboard drifting occurred on the conveying belt and carton paperboard dropping from the conveying belt are avoided, drifting detection can be conducted on the paperboards on the conveying belt, and then position correction operation can be performed.

Owner:安吉县格林纸箱厂

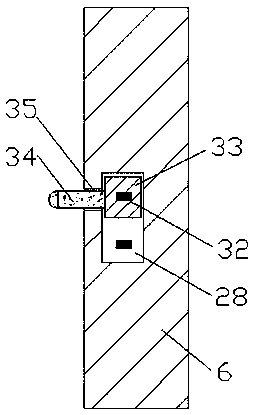

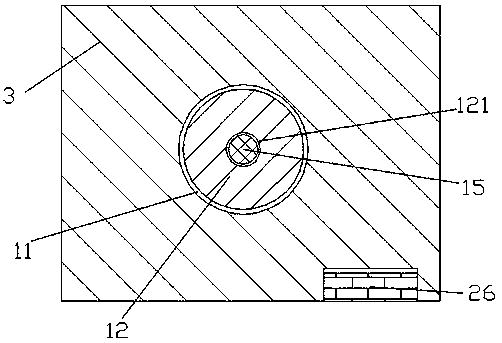

Electric wheel stopping device and three-dimensional garage carrying hanging bracket using the same

Owner:SHANDONG JIU ROAD PARKING EQUIP CO LTD

Paper board conveyor and use method thereof

PendingCN107792694AReduce labor intensityIncrease productivityFunction indicatorsArticle feedersCardboardCarton

The invention discloses a paper board conveyor and a use method thereof. According to the technical scheme, the conveyor comprises a rack and a conveying belt arranged on the rack, a support arrangedon the upper side of the conveying belt is arranged on the rack, an abutting pressing device for colliding with the surface of the conveying belt is arranged on the support, a sliding groove is formedin the support, the section of the sliding groove is in a wedge shape, the end, away from a first pressing rod, of a sliding block is arranged in the sliding groove in a sliding manner, a stroke detecting device colliding with the surface of the conveying belt is arranged on the rack, a marking device is arranged on the rack, a roller of the stroke detecting device collides with the surface of the conveying belt, and a displayer is arranged on the rack, and is connected with the output end of a controller. According to the paper board conveyor, a carton paper board can be pressed on the surface of the conveying belt in an abutting manner, drifting of the carton paper board on the conveying belt and falling off from of the conveying belt can be avoided, the paper board surface can be marked, and a worker can conveniently carry out bending operation on the paper board.

Owner:安吉县格林纸箱厂

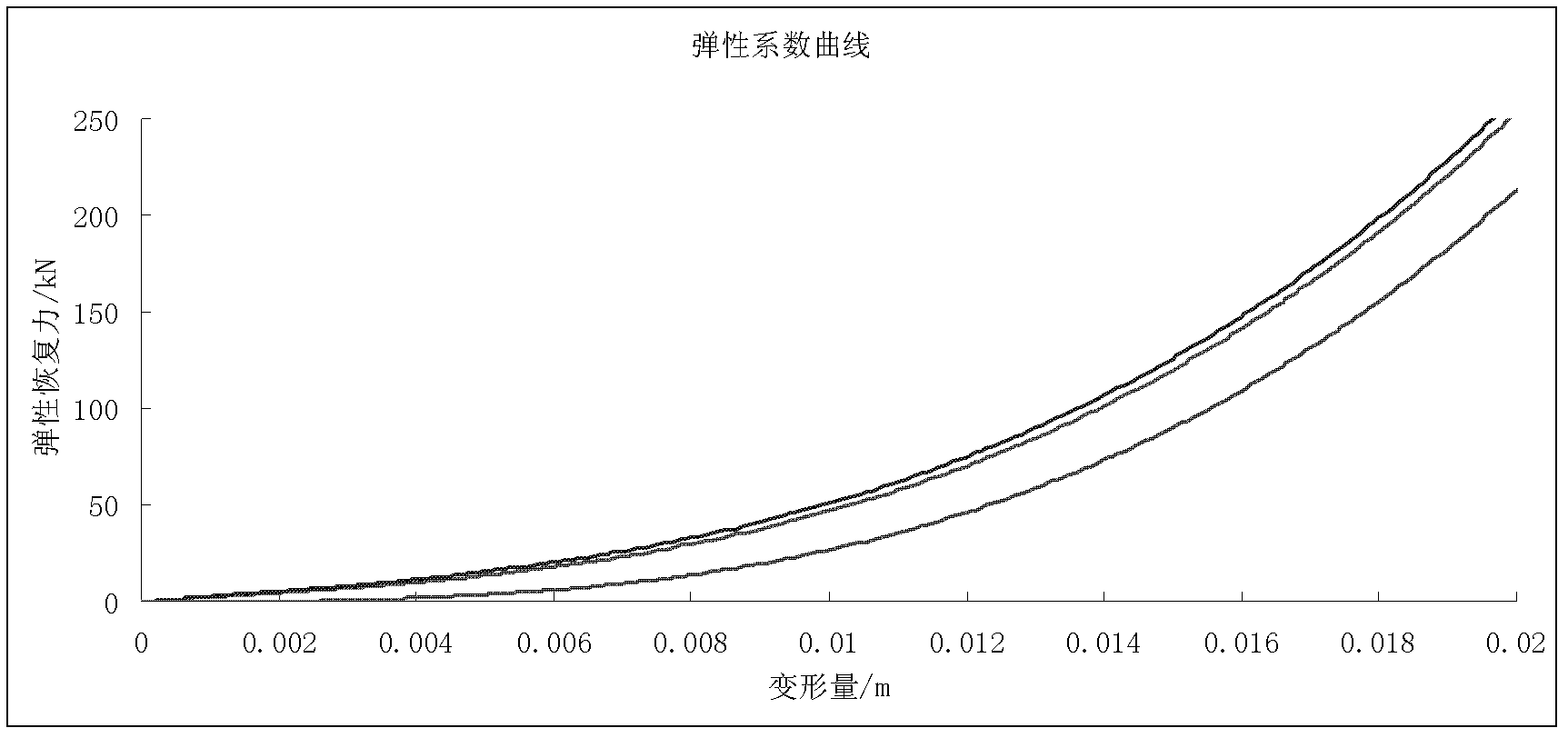

Diaphragm type long-travel unidirectional spring mechanism

The invention discloses a diaphragm type long-travel unidirectional spring mechanism, which is characterized by a diaphragm elastic device, a rigidity output end gear rack mechanism, a displacement amplifying mechanism and a working end gear rack mechanism, wherein the diaphragm elastic device provides elastic rigidity for the whole mechanism, and consists of supporting cylinders, an annular filmbelt, a tension device and a connector; not less than 2 cylinders are fixed on a cabinet and used for supporting the annular film belt; one end of the connector is linearly contacted with the annularfilm belt, and the other end of the connector is in rigid connection with a rack; the rigidity output end gear rack mechanism consists of a gear rack mechanism, a rack is connected with a rigidity output connector, and the bottom of the rack is provided with guide rollers connected with the cabinet body; the displacement amplifying mechanism is a planet gear speed increaser, or a cylindrical gearspeed increaser; and the working end gear rack mechanism is used for converting rotary displacement into linear displacement. The structure is a unidirectional long-travel spring; moreover, an analytic expression can be provided for an elastic change curve of the spring, which is important for a design requiring accurate elastic change.

Owner:蔡元奇

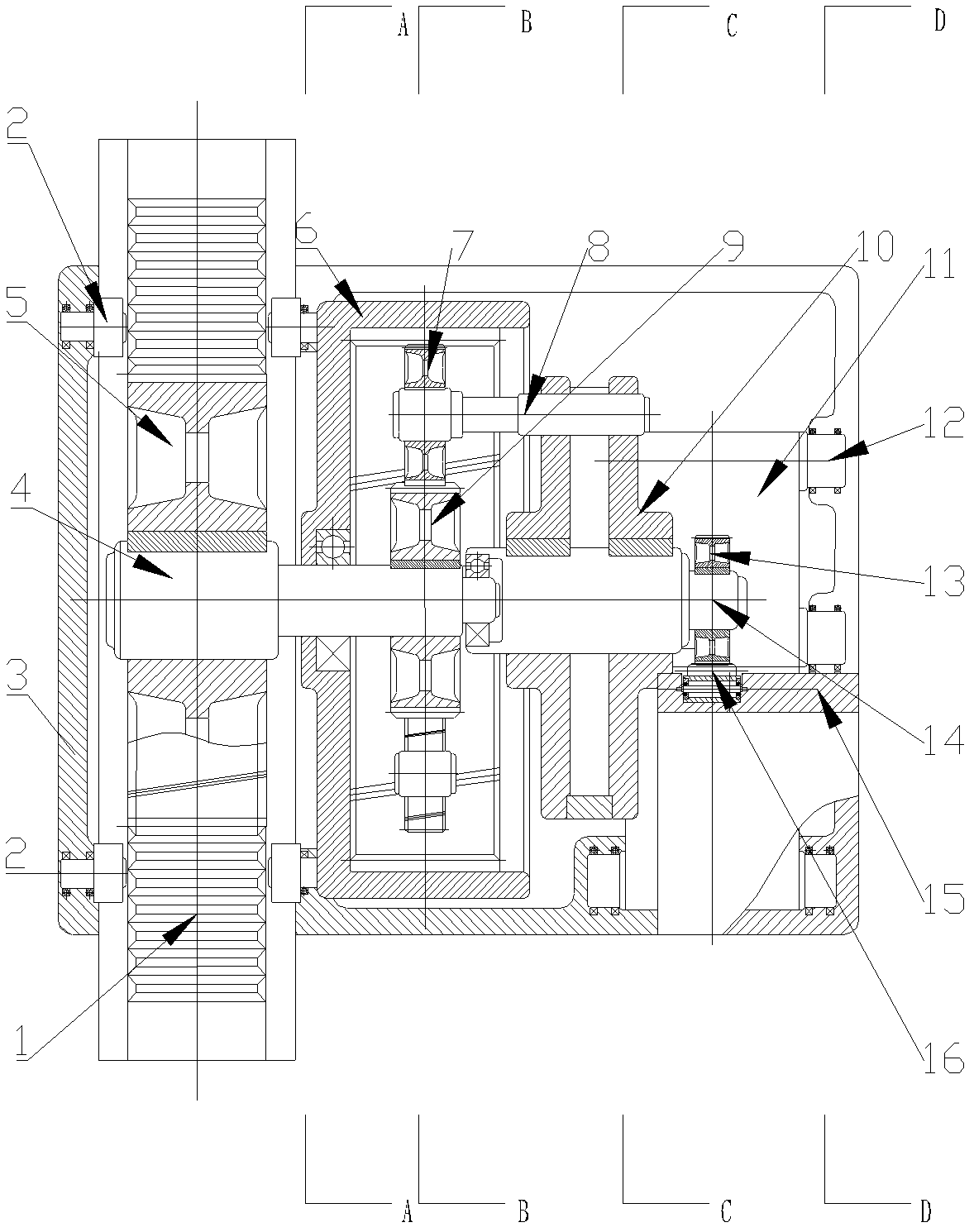

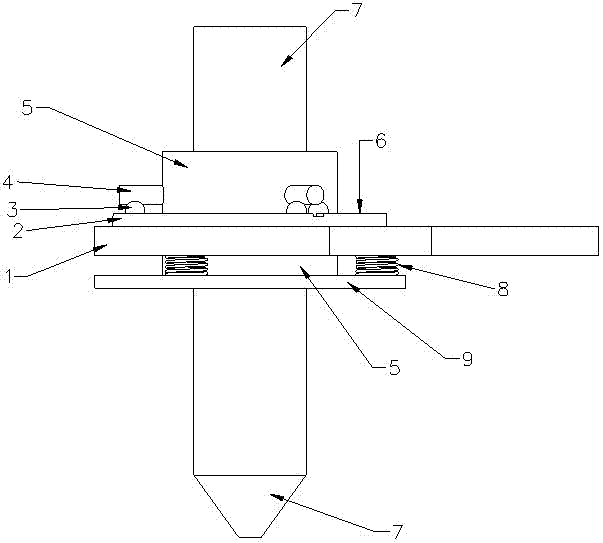

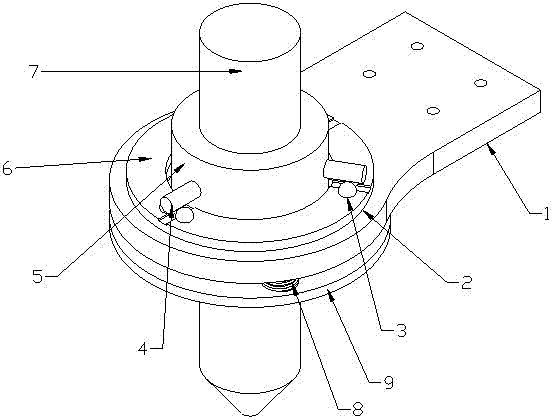

Plasma cutting torch protection and collision detection device of numerically controlled plasma cutting machine

InactiveCN102225489APlay the role of positioningAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesCollision detectionTorch

The invention discloses a plasma cutting torch protection and collision detection device of a numerically controlled plasma cutting machine. A positioning plate is mounted on the base plate of the device. A plasma cutting torch mounting base is mounted in the through holes of the base plate and the positioning plate. The upper surface of the positioning plate is provided with a conductive layer, and three pairs of evenly distributed steel balls which are in contact with the conductive layer are mounted on the positioning plate. Three evenly distributed metal pins are mounted on a plasma cutting torque mounting base, and the metal pins are in contact with the steel balls respectively. The bottom of the plasma cutting torque mounting base is provided with a flange, and three springs are evenly distributed between the flange and the base plate. A plasma cutting torch is mounted in the mounting hole of the plasma cutting torch mounting base. One end of a wiring terminal is connected to a numerical control system, while the other end of the wiring terminal is connected to the conductive layer. The device provided by the invention is capable of preventing the plasma cutting torque from being collided and damaged while cutting a metal; under support of the numerical control system, the system is used for measuring the distance between the plasma cutting torque and a steel plate at the beginning of cutting, so that the cutting height is automatically set, and the production efficiency and the cutting quality are improved.

Owner:GUANGDONG UNIV OF TECH

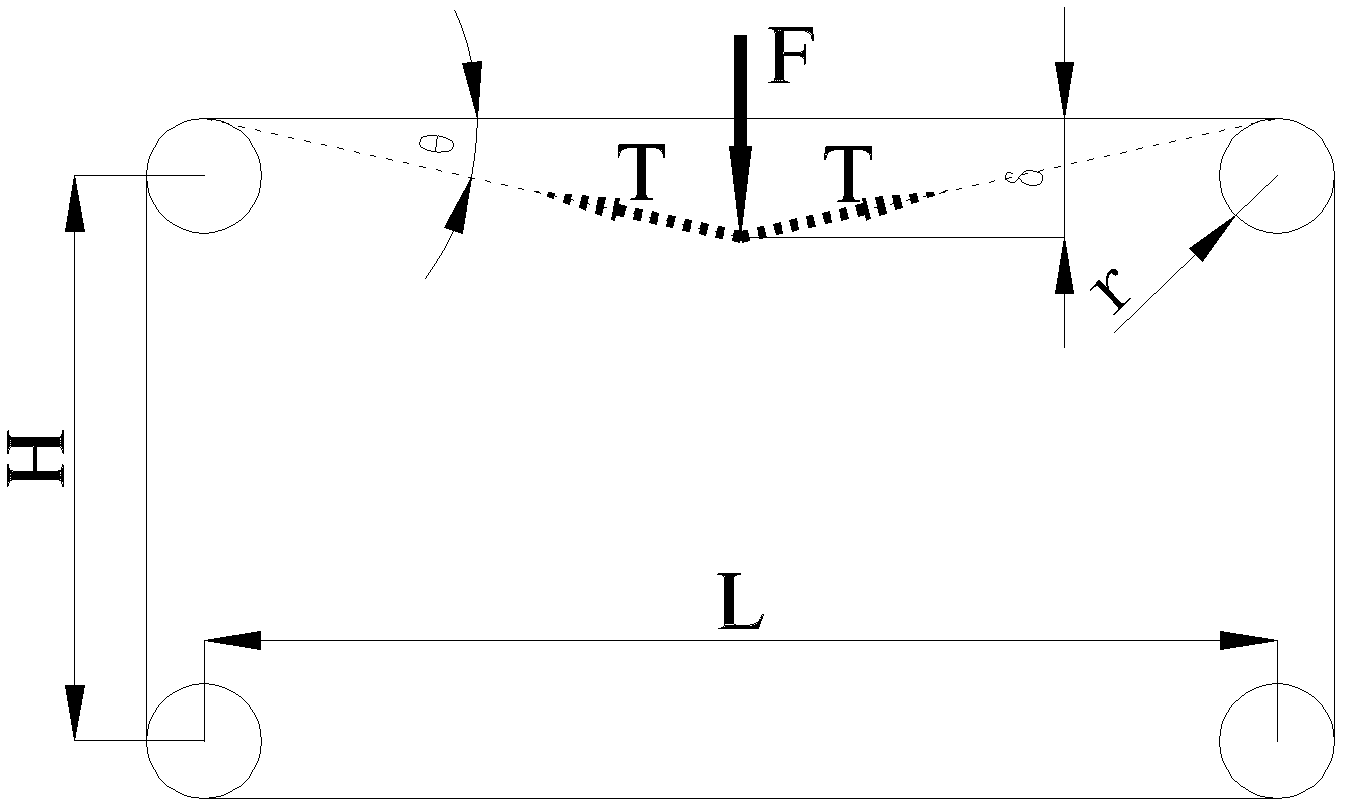

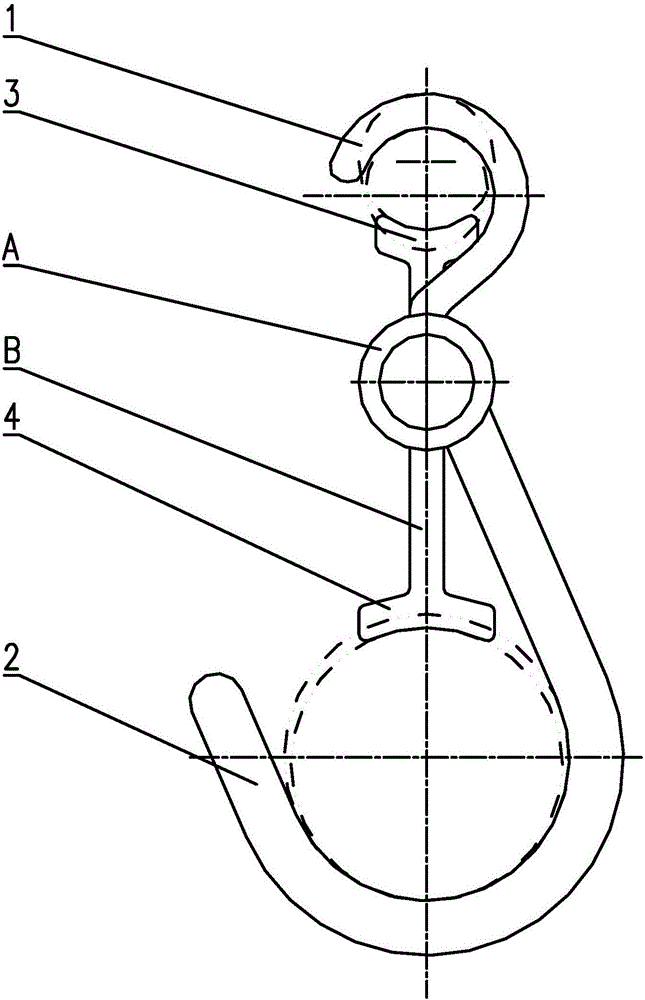

Tension self-locking type power transmission cable suspension tool for power transmission line

InactiveCN106374409AGuaranteed reliabilityEasy to useAdjusting/maintaining mechanical tensionStatic frictionSelf locking

The invention discloses a tension self-locking type power transmission cable suspension tool for a power transmission line, and belongs to the field of power transmission line tools and machine tools. The tension self-locking type power transmission cable suspension tool consists of a hook body and an eccentric bracket, wherein an upper hook and a lower hook are connected with each of two ends of the hook body separately; the eccentric bracket is provided with an upper supporting top and a lower supporting top separately; the eccentric bracket is connected in the middle of the hook body; the upper hooks at two ends of the hook body are suspended on a steel wire rope, which is fixedly connected in a tensioning manner, to enable the steel wire rope to be correspondingly supported by the upper supporting top of the eccentric bracket; and the power transmission cable is correspondingly suspended on the lower hooks at two ends of the hook body and supported by the corresponding lower supporting top of the eccentric bracket. According to the tension self-locking type power transmission cable suspension tool, a relative stationary state between the hook and the steel wire rope, and between the hook and the power transmission cable without displacement is realized through static friction force, thereby ensuring the reliability and the safety in use of the hook for the power transmission cable.

Owner:武汉长江船舶设计院有限公司

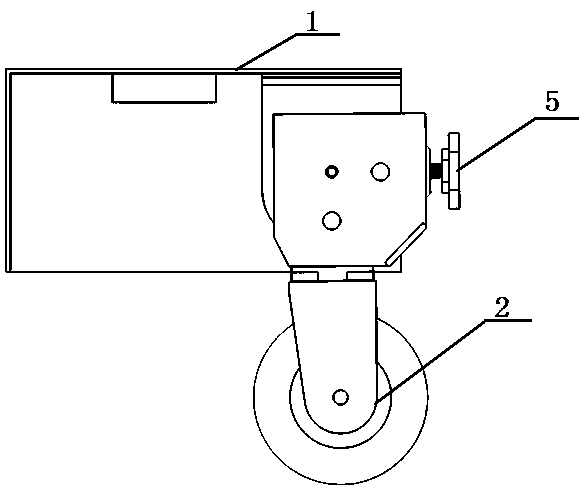

Roller and foundation bolt switching type box supporting structure

Owner:SOUTHEAST UNIV

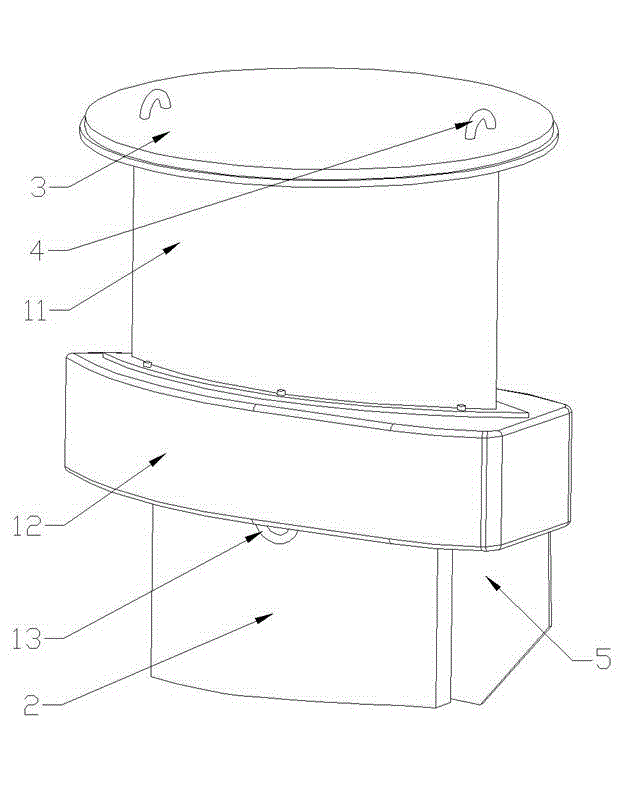

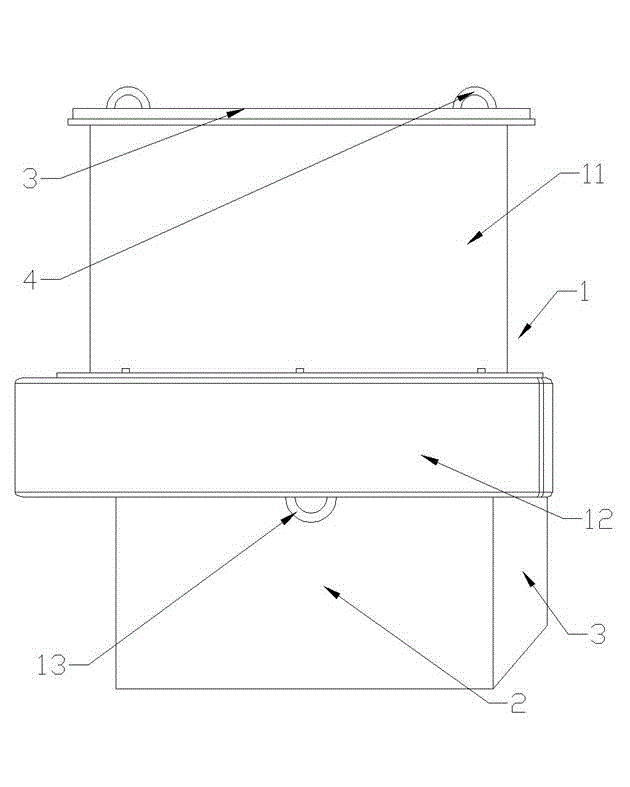

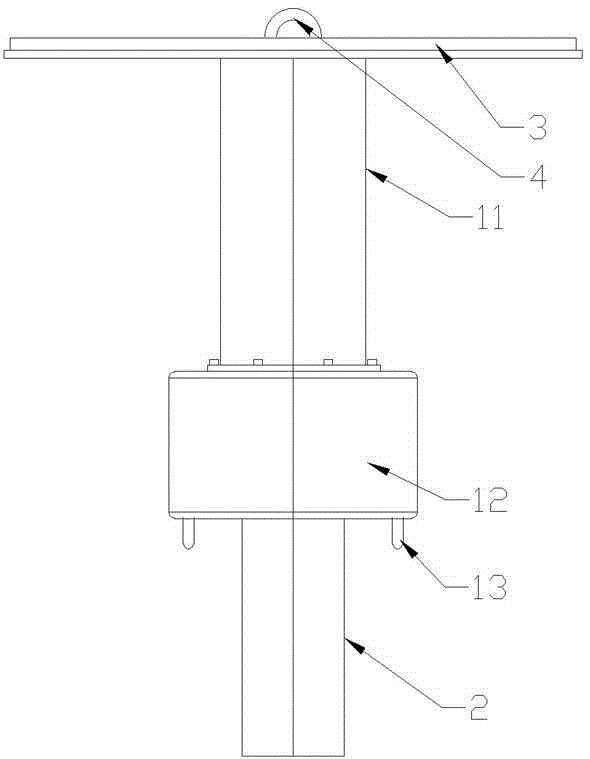

Underwater floating body and buoyance device comprising same

ActiveCN103552658AReduce the stress areaReduce forceWaterborne vesselsBuoysBuoyant flowNavigation function

The invention provides a buoyance device which aims at effectively preventing self-displacement on the water surface and effectively providing an aid-to-navigation function and an underwater floating body being comprised in the buoyance device. The underwater floating body comprises a floating body (1) and a counter weight body (2) which is arranged on the lower portion of the floating body (1); the floating body (1) is in a streamline shape; the buoyance device comprises the floating body and a lighthouse (6) which is fixedly arranged on the floating body (1). The underwater floating body and the buoyance device comprising same can be applied to the field of aid-to-navigation devices.

Owner:ZHUHAI TIANYUE TECH

Intelligent checkout stand for stamping parts

InactiveCN107053101AConvenient inspectionImprove stabilityLighting elementsWork benchesLight pipeEngineering

The invention discloses an intelligent checkout stand for stamping parts. The intelligent checkout stand for the stamping parts comprises a chassis, a lamp holder, a lamp tube assembly, a lifting device, a checkout stand body and a scanning system. The intelligent checkout stand for the stamping parts is characterized in that the rotatable lamp holder is arranged on the rear side face of the chassis and fixedly provided with the lamp tube assembly; the chassis is provided with the lifting device used for ascending or descending of the checkout stand body, and the checkout stand body is installed on the lifting device; the scanning system comprises a scanning host, a scanning probe and a manipulator; the scanning host is fixed on the left side face of the chassis; a manipulator base is installed on the left side face of the chassis; and the manipulator is provided with the scanning probe for scanning. The intelligent checkout stand for the stamping parts can obtain the causes of unqualified products through quick analysis based on multi-angle checkout, a good light environment and historical data checkout records and checkout analysis, can also provide corresponding solutions and has a good checkout effect for the stamping parts.

Owner:JINGXI XIUMEI BIANCHENG AGRI SCI & TECH CO LTD

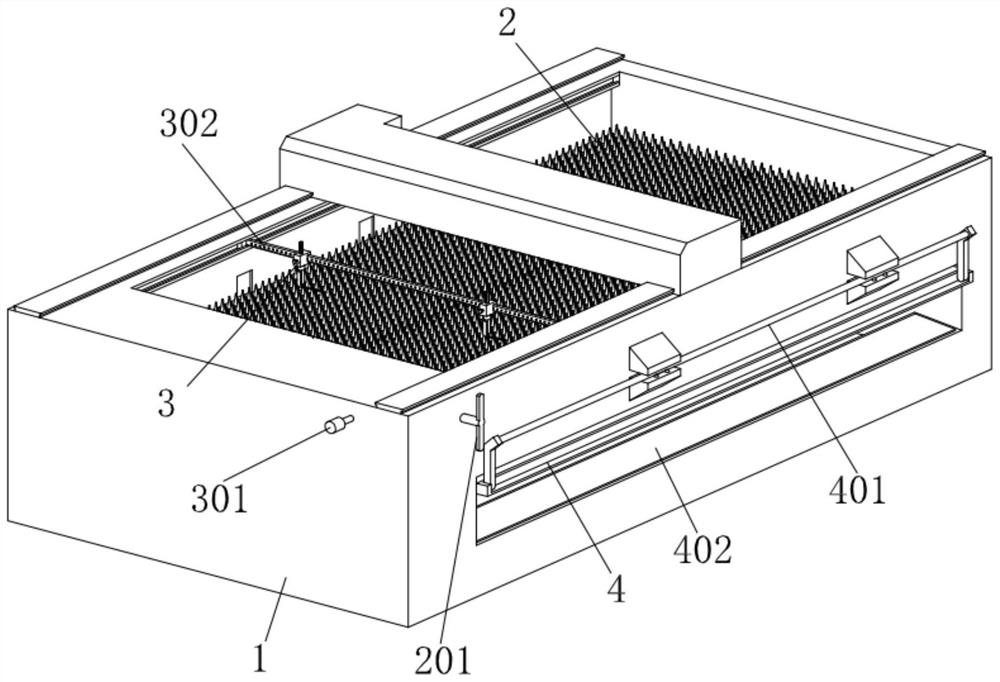

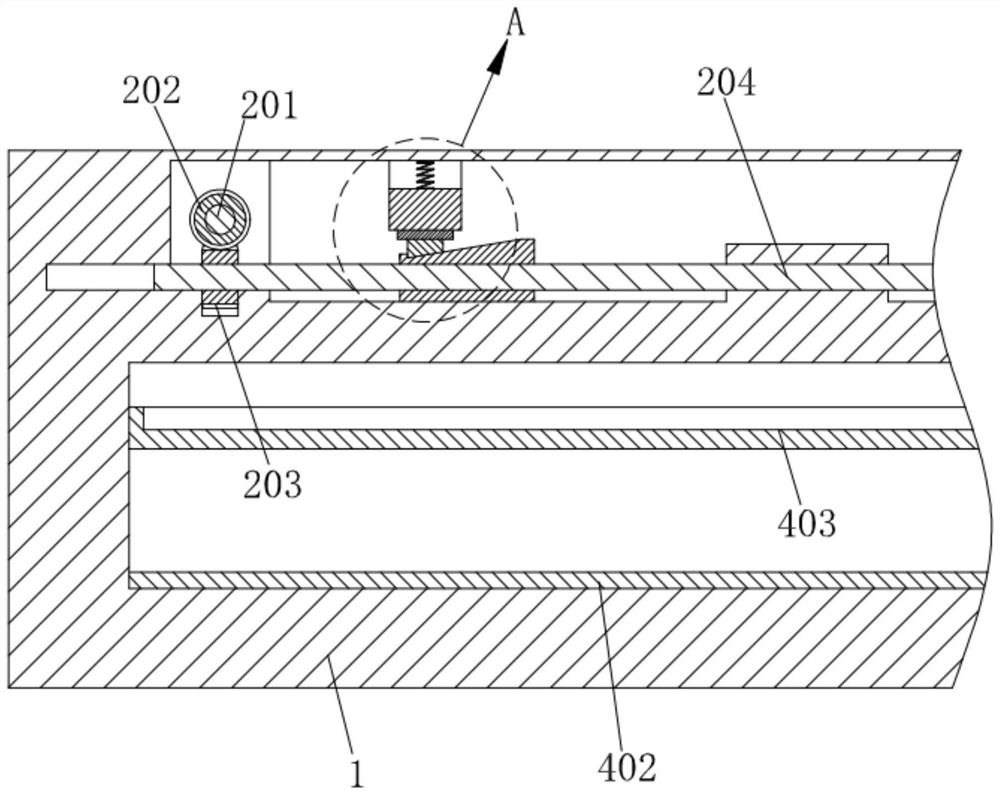

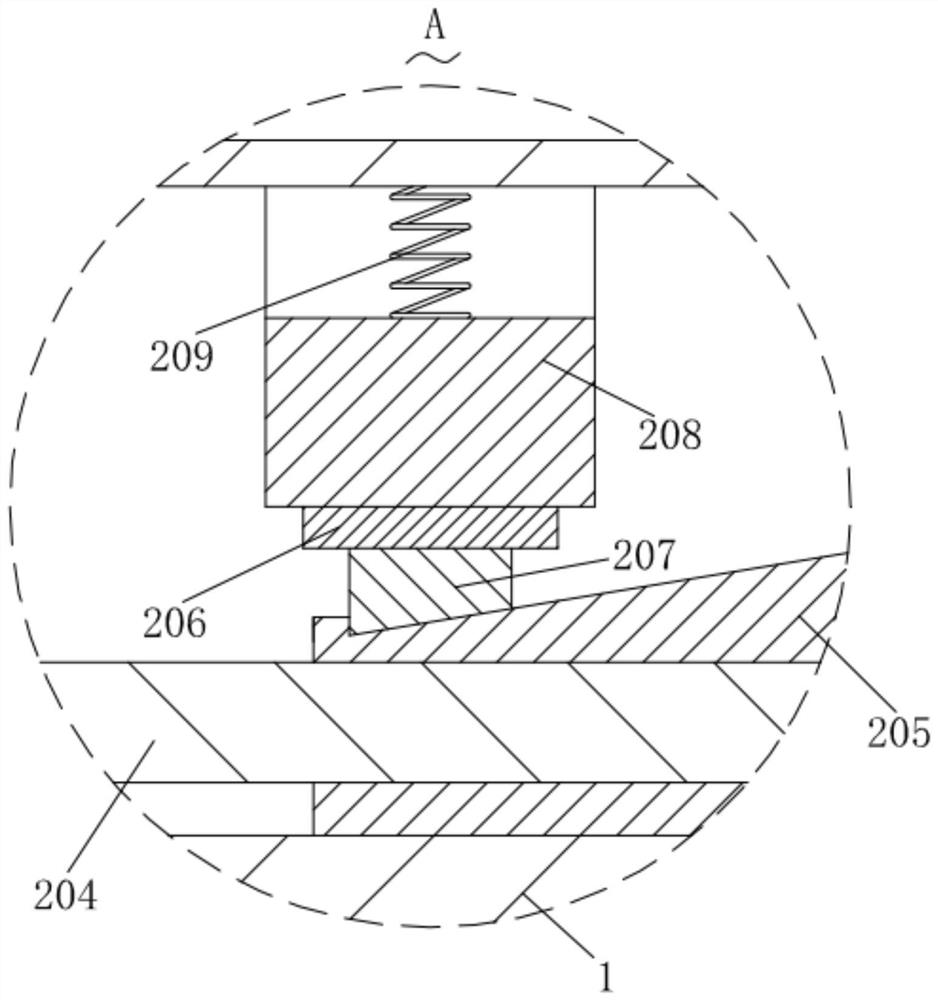

Laser cutting equipment for production and processing

ActiveCN114160999AAvoid enteringFor precise cuttingLaser beam welding apparatusEngineeringLaser cutting

The invention relates to the technical field of laser cutting, in particular to laser cutting equipment for production and processing, which comprises a cutting machine body, a bearing structure is arranged on the inner side of the cutting machine body, a collecting structure is mounted on the bottom side of the bearing structure, and a hanging structure is connected between the collecting structure and the cutting machine body. A bearing structure is arranged on the cutting machine body, a positioning structure is arranged on the cutting machine body, a fixing structure is arranged on the positioning structure, accurate height adjustment can be carried out on a nail plate for containing a plate through the bearing structure, the cutting accuracy is guaranteed, cut materials and chippings can be collected in a centralized mode through a collecting structure, and use is convenient. The horizontal state of the collecting plate can be fixed through the hanging structure, stability is guaranteed, the positions of plates placed in different areas can be fixed through the positioning structure, the influence on cutting equipment is reduced, and the plates of different sizes can be conveniently fixed through the fixing structure.

Owner:江苏三州机械科技有限公司

Underwater floating body and buoyancy device including the floating body

The invention provides a buoyance device which aims at effectively preventing self-displacement on the water surface and effectively providing an aid-to-navigation function and an underwater floating body being comprised in the buoyance device. The underwater floating body comprises a floating body (1) and a counter weight body (2) which is arranged on the lower portion of the floating body (1); the floating body (1) is in a streamline shape; the buoyance device comprises the floating body and a lighthouse (6) which is fixedly arranged on the floating body (1). The underwater floating body and the buoyance device comprising same can be applied to the field of aid-to-navigation devices.

Owner:ZHUHAI TIANYUE TECH

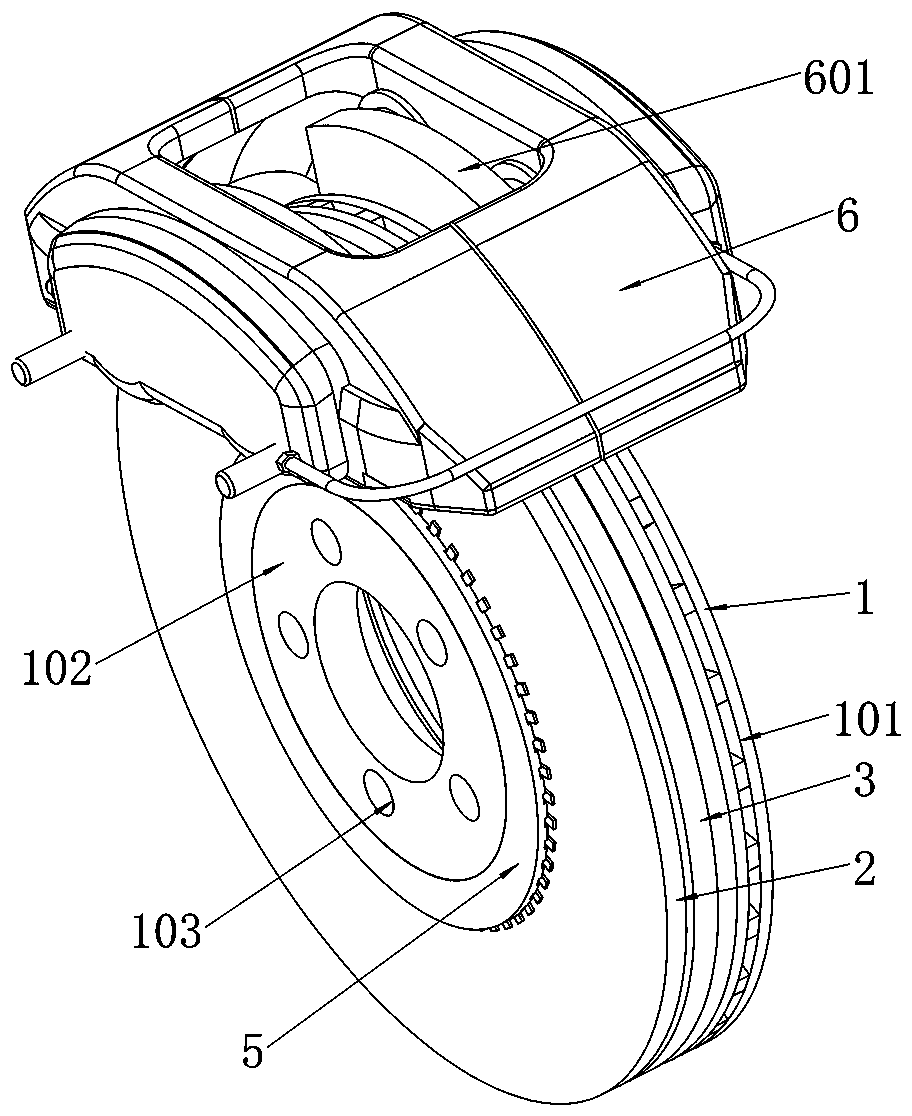

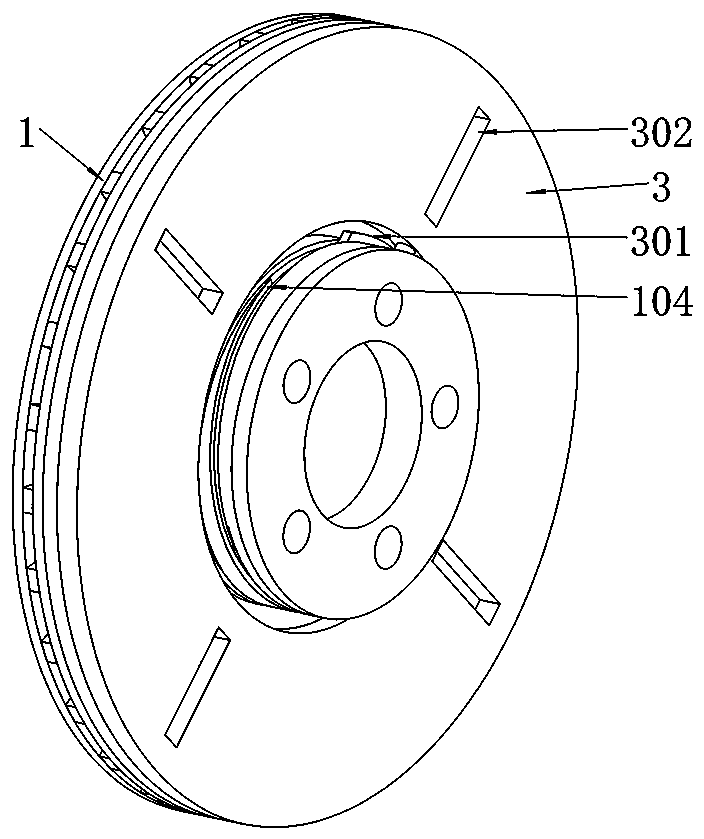

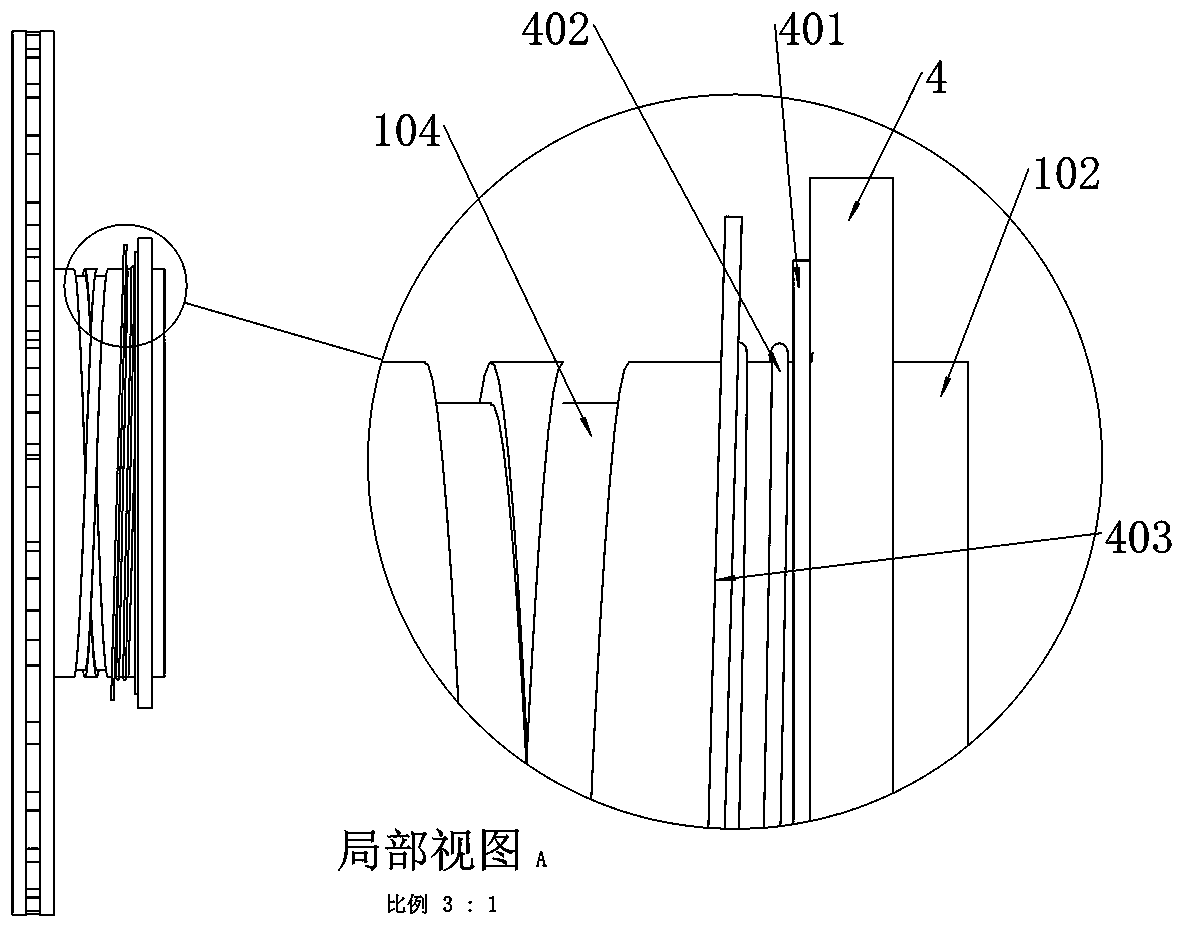

Assembly type anti-lock brake disc

InactiveCN109404444AShort braking effectEnsure intermittent braking effectAxially engaging brakesBraking discsEngineeringMechanical engineering

The invention relates to the technical field of automobile brake discs, in particular to an assembly type anti-lock brake disc. The left end of a first brake disc is equipped with a second brake disc;during emergency braking, a brake clamp simultaneously brakes the first brake disc and the second brake disc; under action of the brake clamp, the second brake disc stops rotation; the brake effect of the brake clamp only acts on one surface of the first brake disc, so that the first brake disc does not stop rotation to have a lock phenomenon; the first brake disc continuously rotates to drive amovable disc to automatically move; after a second friction plate is in contact with the first brake disc, the movable disc reversely moves under action of two-way threads while a transient brake effect can be provided for the first brake disc; the movable disc moves back and forth, and intermittent brake effect can be generated on the second brake disc, so that wheels are prevented from being suddenly locked during emergency braking, and therefore, the problems that a car generates sideslip and the car loses direction manoeuverability as the wheels are suddenly locked during emergency brakingare solved.

Owner:河北百龙汽车配件股份有限公司

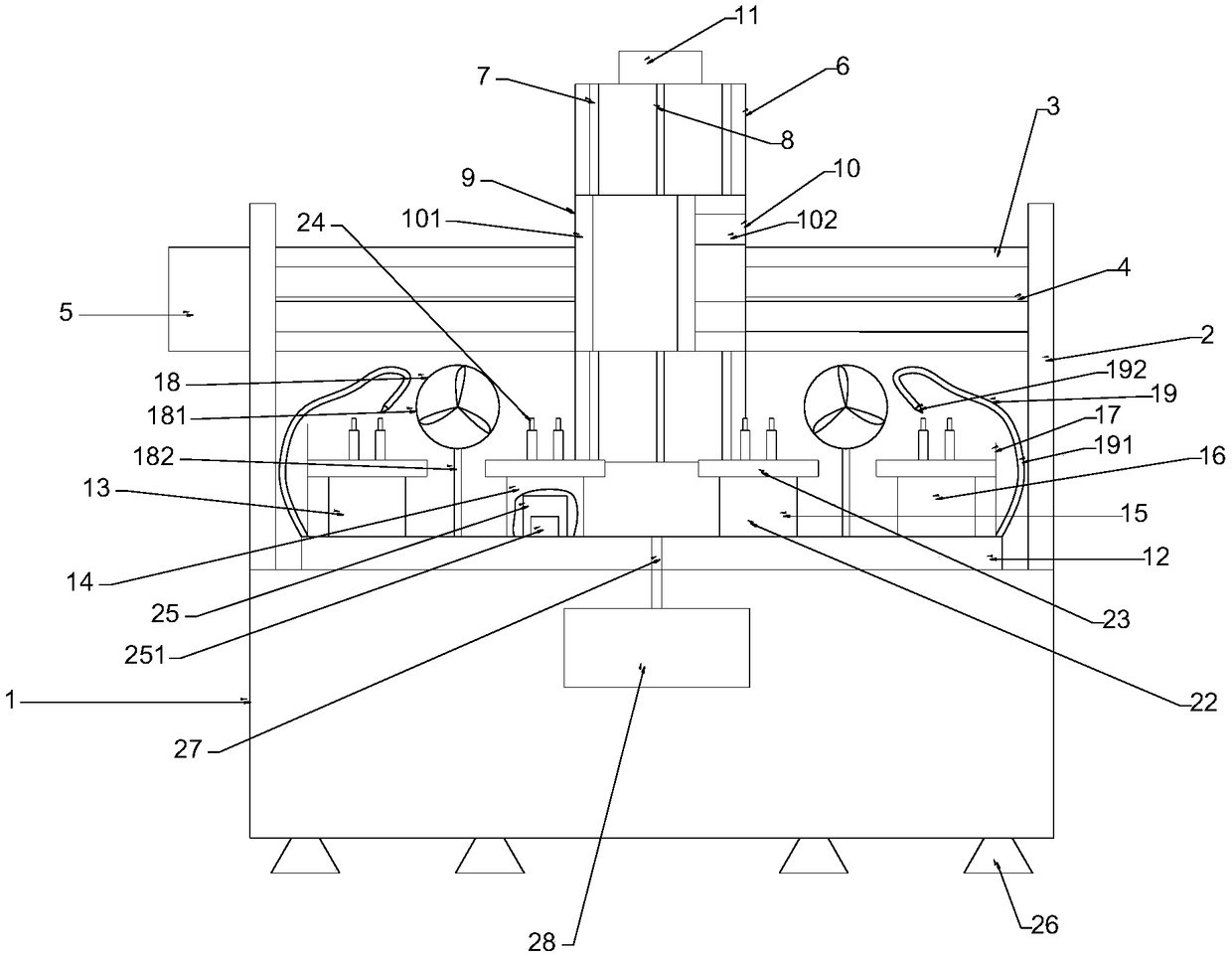

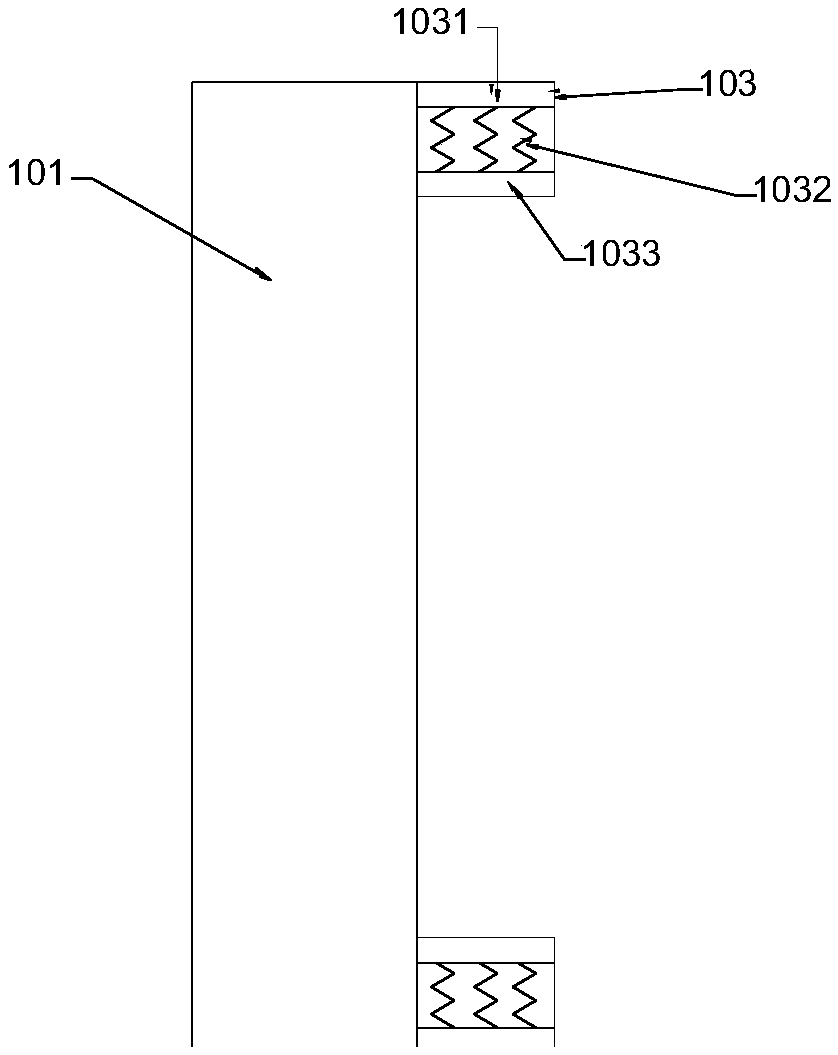

Automatic numerically-controlled machine tool

ActiveCN108907720AReduce vibrationNo offsetOther manufacturing equipments/toolsNumerical controlElectric machinery

The invention belongs to the technical field of numerically-controlled machine tools, and provides an automatic numerically-controlled machine tool. The automatic numerically-controlled machine tool comprises a machine tool; stand columns are arranged at the two ends of the machine tool, a transverse guide rail, a first lead screw and a first motor are arranged on the stand columns, the transverseguide rail is parallel to the first lead screw, and the first motor is connected to the first lead screw; a transverse moving platform is arranged on the transverse guide rail, the first lead screw is connected to the transverse moving platform through a nut, and a longitudinal guide rail, a second lead screw and a second motor are arranged on the transverse moving platform; and a longitudinal moving platform is arranged on the longitudinal guide rail, the second lead screw is connected to the longitudinal moving platform through a nut, a clamping device used for fixing a workpiece is arranged on the longitudinal moving platform, and the second motor is connected to the second lead screw. The technical problems that in existing traditional multi-shaft drilling and tapping, if a drill jigguider is not adopted, the hole position degree deviation is large, a screw tap is prone to being damaged, and then a workpiece is scrapped; and if the drill jig guider is adopted, secondary clampingerrors exist and automatic machining is inconvenient to achieve due to technology reasons are solved.

Owner:高邑县云发专用机床厂

Automatic pin inserting device

InactiveCN110052804AAutomatic pin insertionImprove work efficiencyMetal working apparatusEngineeringConveyor belt

The invention belongs to the technical field of automatic pin inserting, in particular to an automatic pin inserting device. The automatic pin inserting device comprises supporting legs, wherein a transverse plate is fixedly connected to the side surfaces of the supporting legs, a supporting frame is fixedly connected to the upper surface of the transverse plate, a motor is fixedly connected to the upper surface of the supporting frame, the side surface of the motor is fixedly connected with a first rotating disc through an output shaft, the surface of the first rotating disc is movably connected with a conveyor belt, a short rod is fixed on the side surface of one supporting leg, one end of the short rod is fixedly connected with a bearing, and the bearing is fixedly connected to the interior of the other first turntable. According to the automatic pin inserting device, pins are fixed through fixing buckles and second springs, a plurality of inserting holes are arranged for the plurality of pins to insert therein at a time, and the pins are impacted into a mold through collision blocks, so that automatic pin inserting is realized, and the working efficiency is improved; the motoris arranged to drive the conveyor belt to move to enable the mold to move automatically; and the mold is fixed by fixing blocks, so that the mold does not move.

Owner:KUNSHAN YOURUIQUAN PRECISION COMPONENTS CO LTD

Paperboard conveying line facilitating carton production and use method thereof

PendingCN107792693AReduce labor intensityIncrease productivityPaper-makingBox making operationsCardboardEngineering

The invention discloses a paperboard conveying line facilitating carton production. According to the technical scheme, the paperboard conveying line is characterized by comprising a rack and a conveying belt arranged on the rack; a support located on the upper side of the conveying belt is arranged on the rack, an abutting pressing device is arranged on the support, a stoke detection device abutting against the surface of the conveying belt is arranged on the rack, a marking device is arranged on the rack, guide strip plates are arranged on the rack, infrared detectors are arranged on the guide strip plates, a processor is arranged on the rack, and resetting devices which are used for resetting paperboards are arranged at the positions, on the two sides of the conveying belt, of the rack correspondingly. By the adoption of the paperboard conveying line facilitating carton production, the carton paperboards can abut against the surface of the conveying belt in a pressed manner, the situations that the carton paperboards drift on the conveying belt and fall off from the conveying belt are avoided, the drifting detection and the reset operation can be conducted on the paperboards on the conveying belt, the surfaces of the paperboards can be marked, and the paperboards can be bent by workers conveniently.

Owner:安吉多美家具厂

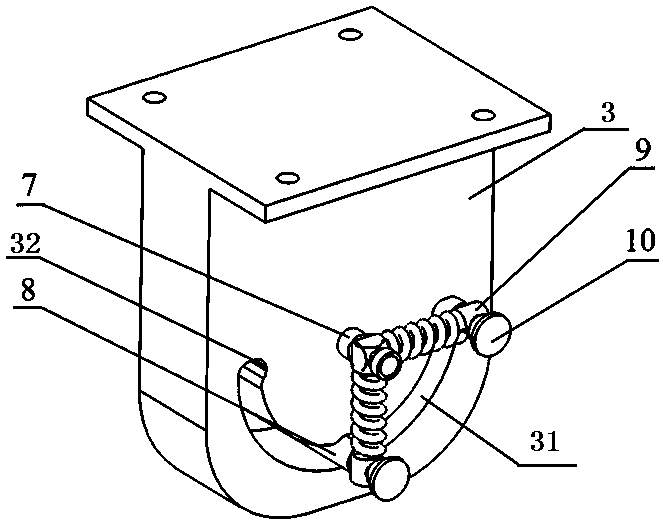

Positioning device capable of intelligently positioning lifting and transversely moving upper car carrier plate

The invention relates to lifting and transversely moving parking equipment, in particular to a positioning device capable of intelligently positioning a lifting and transversely moving upper car carrier plate. The positioning device is provided with a positioning block which is fixed to the external lifting and transversely moving upper car carrier plate through a fastener. The positioning block is provided with a U-shaped positioning groove and a fastener mounting hole. The center line of the U-shaped positioning groove of the positioning block almost coincides with the center line of a ground layer transversely moving track, and in the using process, the U-shaped positioning groove is clamped to the ground layer transversely moving track. The situations that when the lifting and transversely moving upper car carrier plate is located on the ground layer statically, front tires of a car are transited to the upper car carrier plate, the upper car carrier plate is made to move out of an original position due to instant impact of the car, and consequently the car carrier plate moves are avoided, potential safety hazards caused by inclination of the car are avoided, and the effect that the upper car carrier plate cannot move when the car drives to the upper car carrier plate is ensured.

Owner:HUBEI GUANGXING PARKING EQUIP CO LTD

Production conveyor for carton paper boards and application method of production conveyor

The invention discloses a production conveyor for carton paper boards. According to the technical scheme, the production conveyor comprises a frame and a conveying belt and is characterized in that the conveying belt is arranged on the frame, the frame is provided with a support located on the upper side of the conveying belt, the support is provided with a pressing device abutted against the surface of the conveying belt, the support is provided with a slide groove, the section of the slide groove is wedge-shaped, one end, away from the corresponding first pressing rod, of each slider is slidably mounted in the slide groove and matched with the slide groove, each slider is provided with a screw hole in a direction facing the slide groove, and a screw is arranged in each screw hole. The production conveyor has the advantages that the carton paper boards can be pressed against the surface of the conveying belt, drifting of the carton paper boards on the conveying belt is avoided, and the carton paper boards are prevented from falling off the conveying belt.

Owner:安吉县格林纸箱厂

Ship stabilizing equipment based on double-body operation and maintenance ship

PendingCN112937788AMovement does not occurCounteract the impact of wavesVessel movement reduction by mass displacementSea wavesMachine

The invention discloses ship stabilizing equipment based on a double-body operation and maintenance ship. The ship stabilizing equipment comprises a base, a support is installed at the center of the top end of the base, a threaded barrel is installed in the support, symmetrical screw rods are clamped in the threaded barrel in a threaded mode, a rotating arm is installed above the support, and first connecting bases are installed at the two ends of the rotating arm correspondingly; a moving rod is installed at the other end of each of the first connecting bases; a spring is installed on the outer side of the moving rod, a cylinder is installed on the outer side of the spring, a second connecting seat is installed at one end of the cylinder, a middle shaft transversely penetrates through the interior of the rotating arm, machine shells are installed at the two ends of the middle shaft, and rotating shafts are installed in the machine shells; the two ends of the rotating shaft are both provided with rotating discs, the symmetrical screws move in the opposite directions so that the base can be fixed in a cabin without moving, the middle shaft is used for driving the rotating discs to rotate, the moving rods move the compression springs so that sea wave impact force borne by the double-body operation and maintenance ship can be counteracted, and the ship body can be kept stable.

Owner:BENGBU SHENZHOU MACHINERY

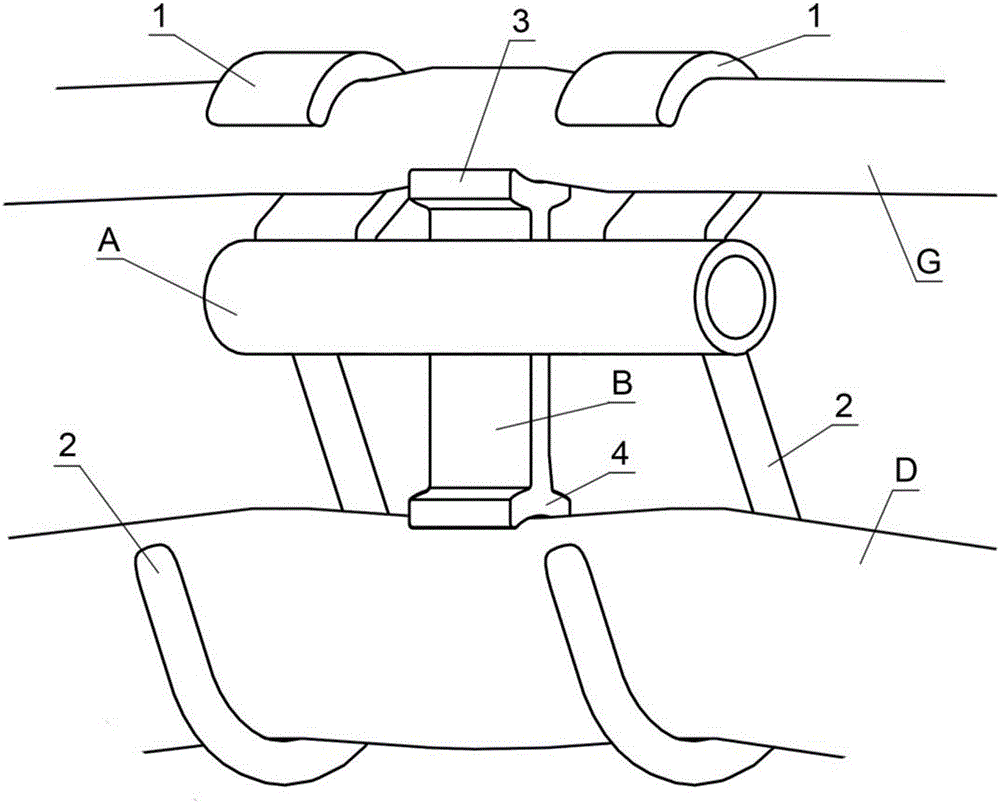

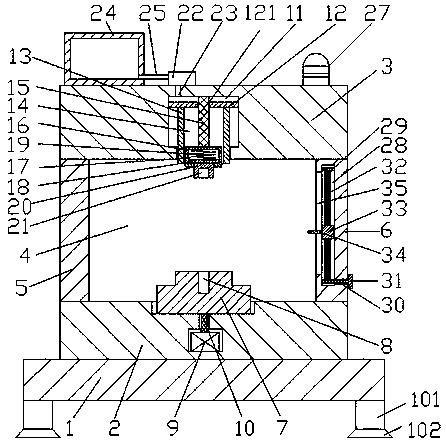

Titanium and titanium alloy welded pipe production technological equipment

InactiveCN108480962AEnsure consistencyMovement does not occurMetal working apparatusTitaniumTitanium alloy

The invention discloses titanium and titanium alloy welded pipe production technological equipment. The titanium and titanium alloy welded pipe production technological equipment comprises a base table. A lower rack is arranged above the upper end face of the base table. A left bearing guide rod and a right bearing guide rod are fixedly and symmetrically arranged on the top end face of the base table in the left-right direction. The top of the left bearing guide rod is fixedly connected with the left end of the bottom face of the lower rack, and the top of the right bearing guide rod is fixedly connected with the right end of the bottom face of the lower rack. A hydraulic cylinder is fixedly arranged in the middle of the top end face of the base table. A jacking hydraulic rod is connectedto the top of the hydraulic cylinder in a matched manner. The top end of the jacking hydraulic rod is fixedly connected with the bottom face of the lower rack, and thus the height of the lower rack isadjusted through the hydraulic cylinder and the jacking hydraulic rod. An upper rack is arranged at the upper side of the lower rack. A cavity is formed between the upper rack and the lower rack. Thetitanium and titanium alloy welded pipe production technological equipment is convenient to use; protective casings are mounted in a sleeving manner automatically; efficiency is high; and finished products are high in quality.

Owner:广州利萨智能化科技有限公司

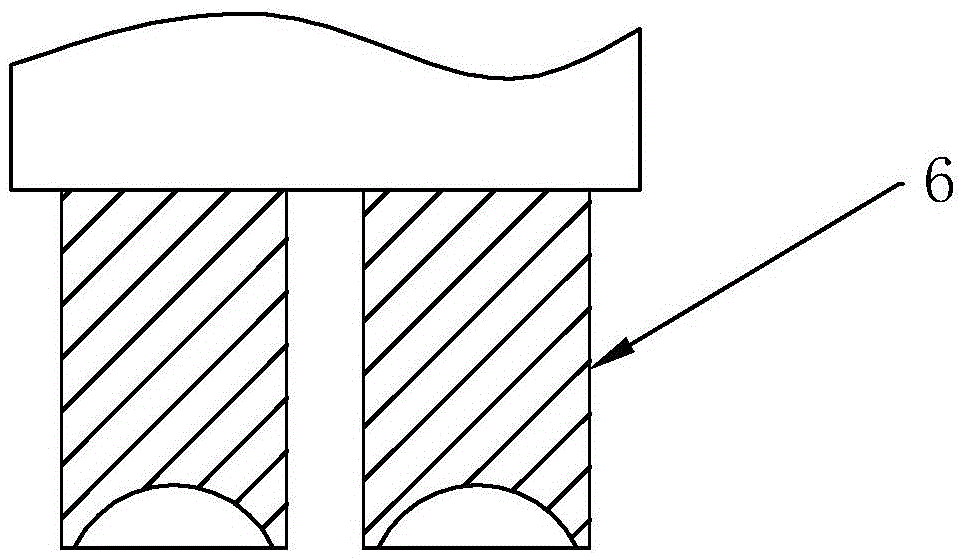

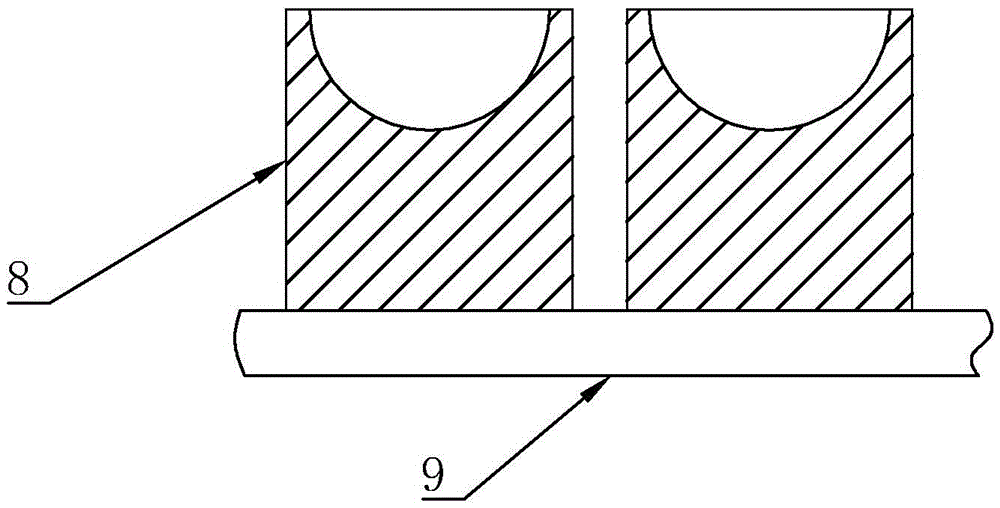

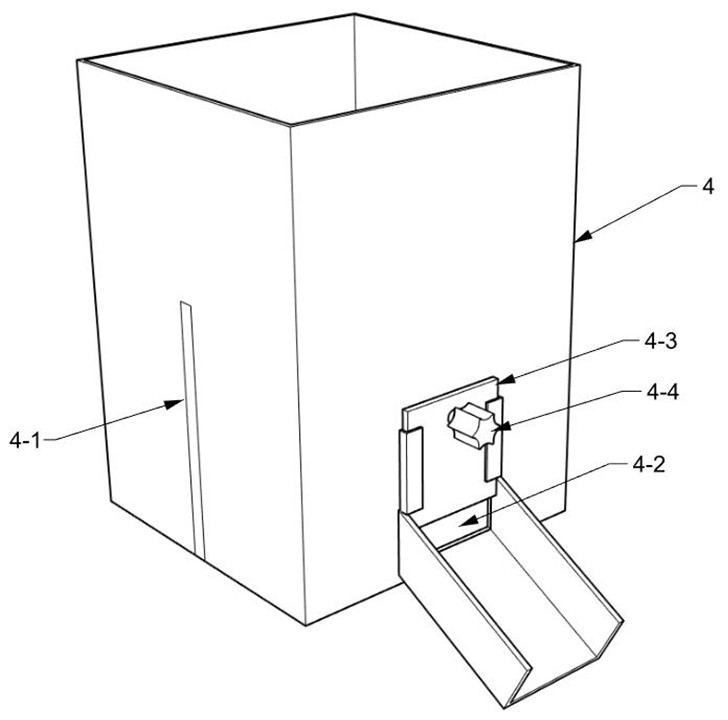

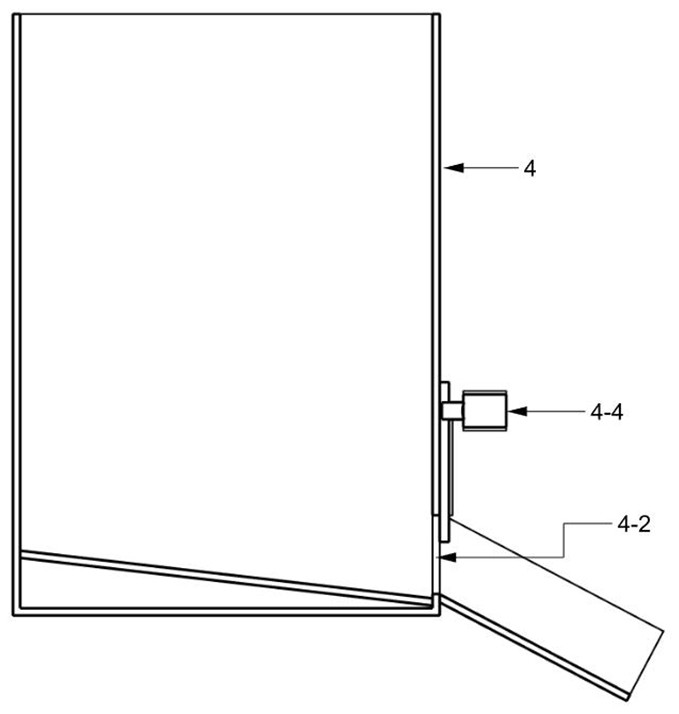

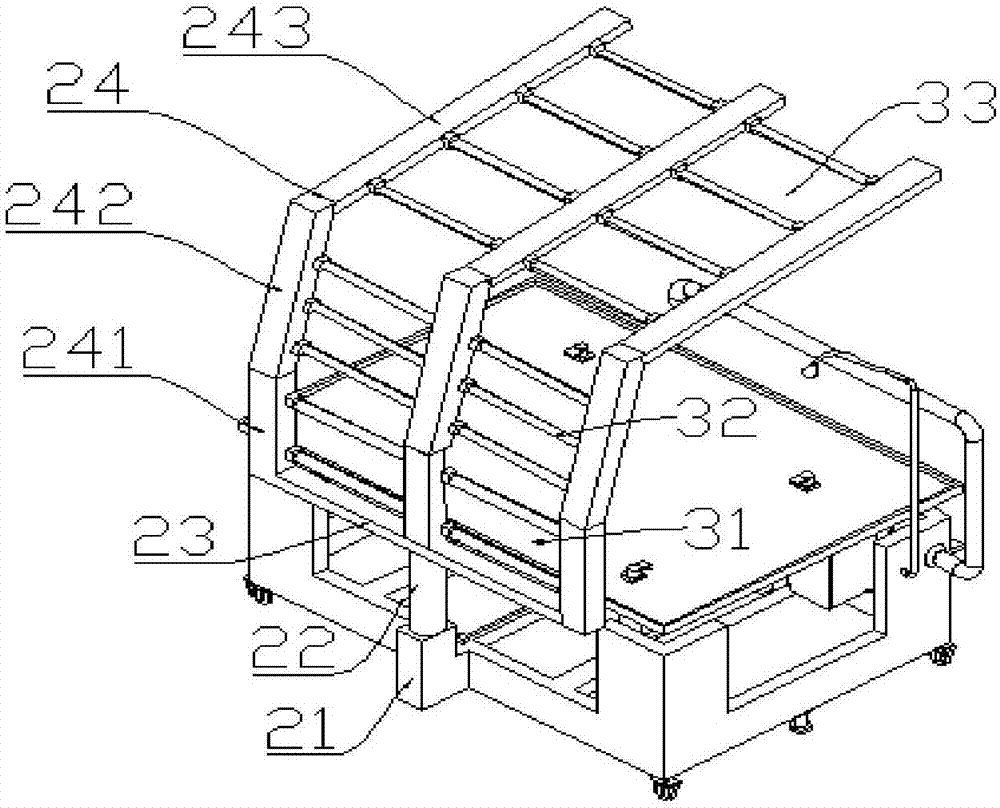

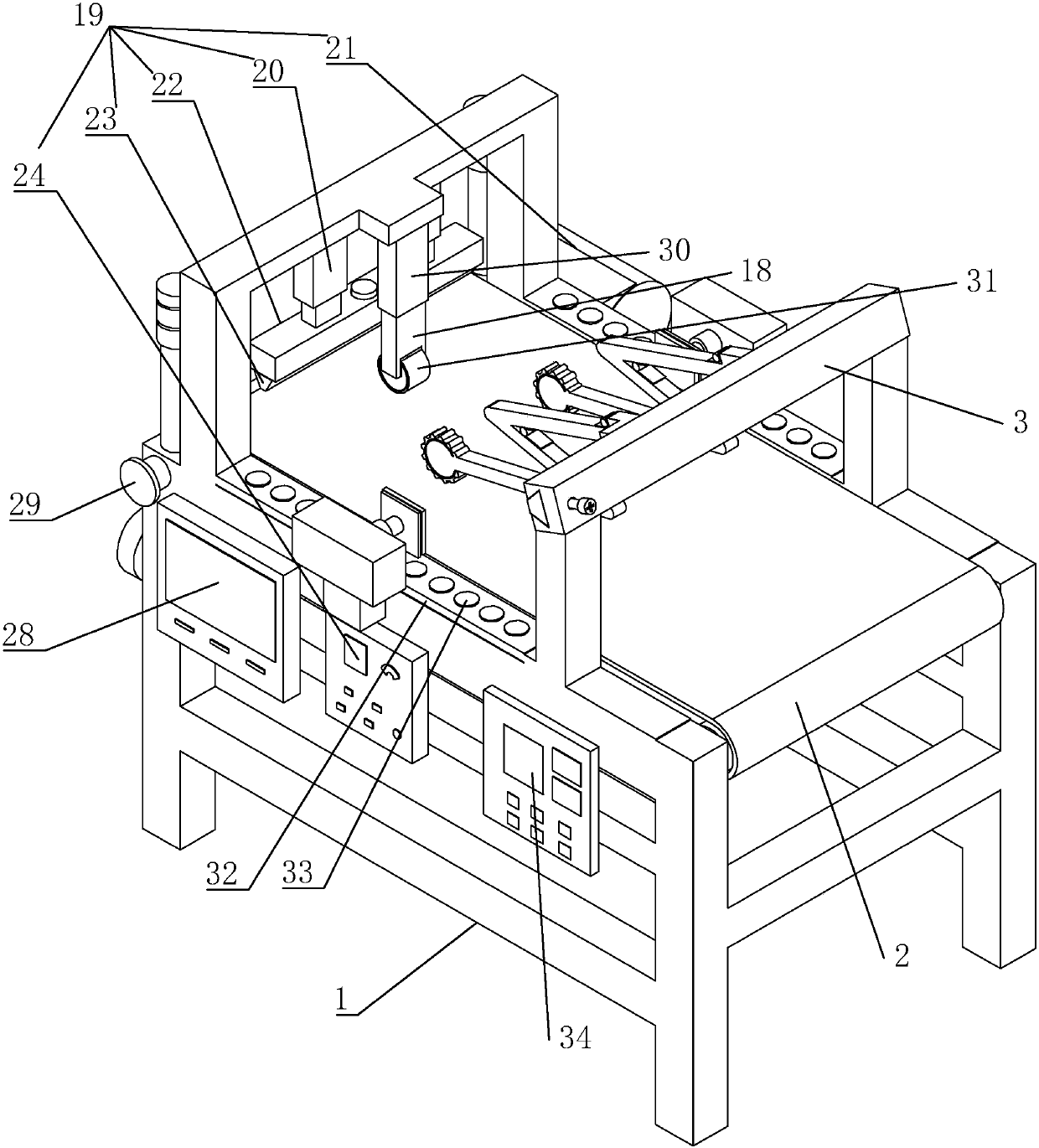

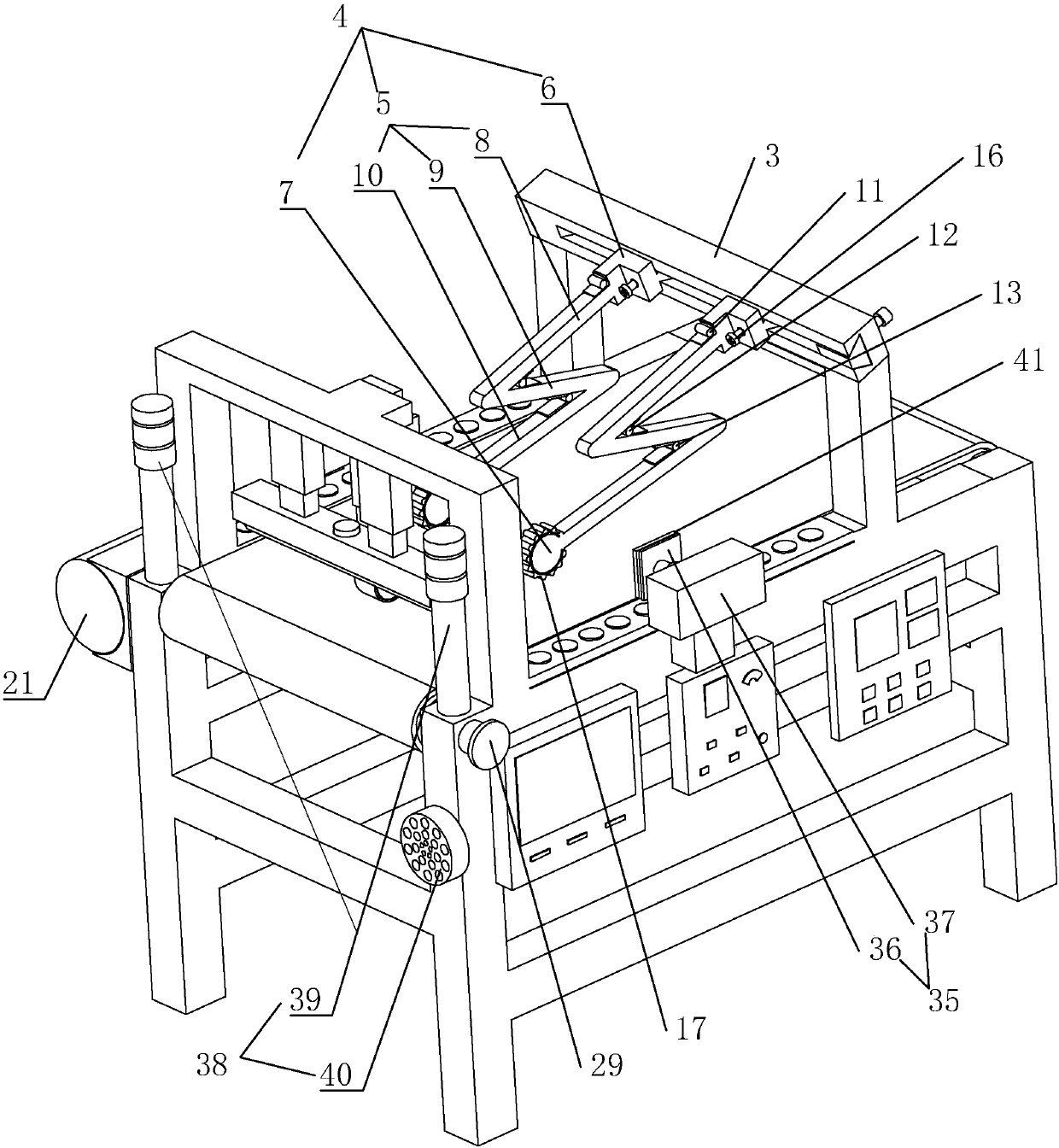

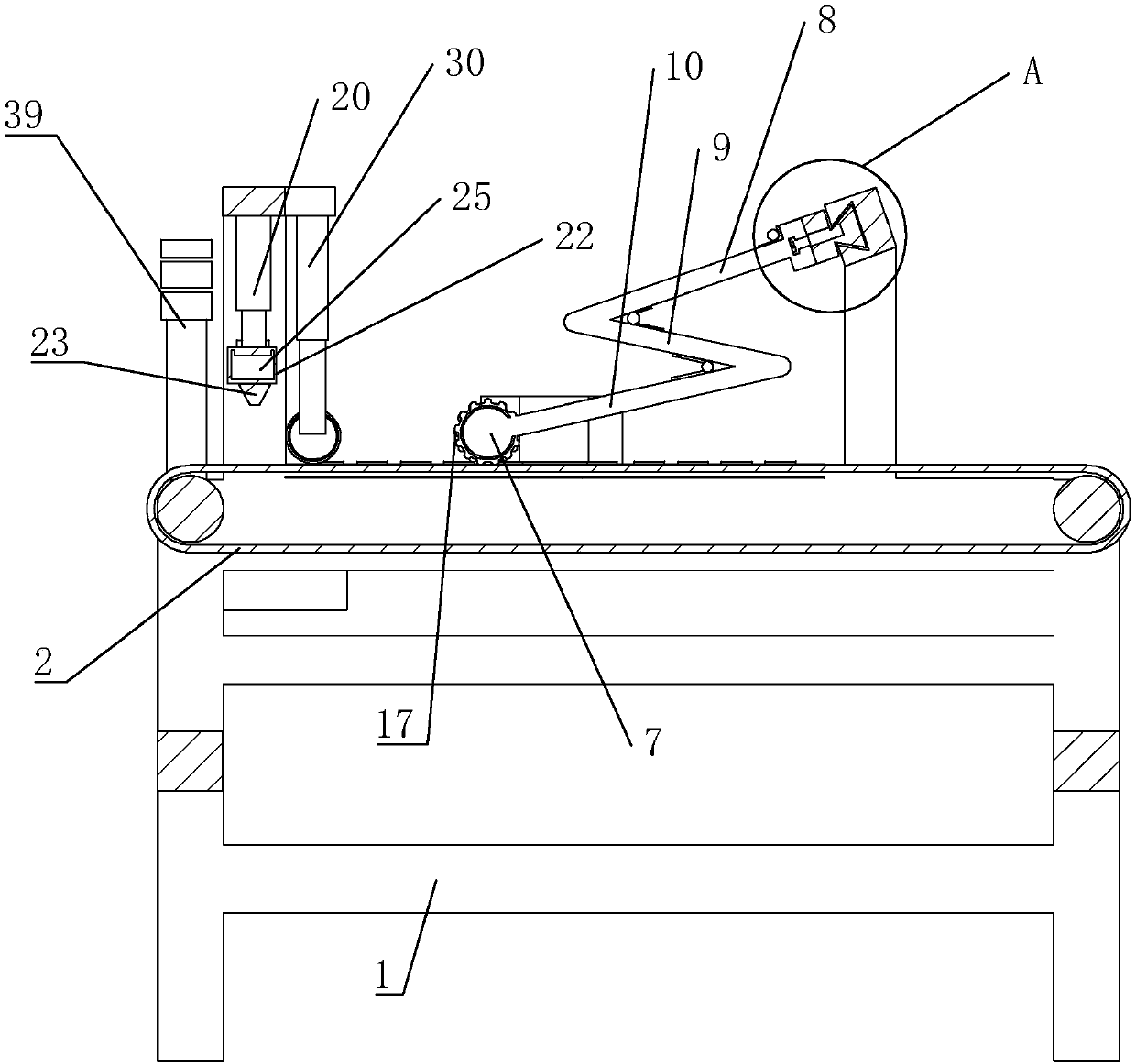

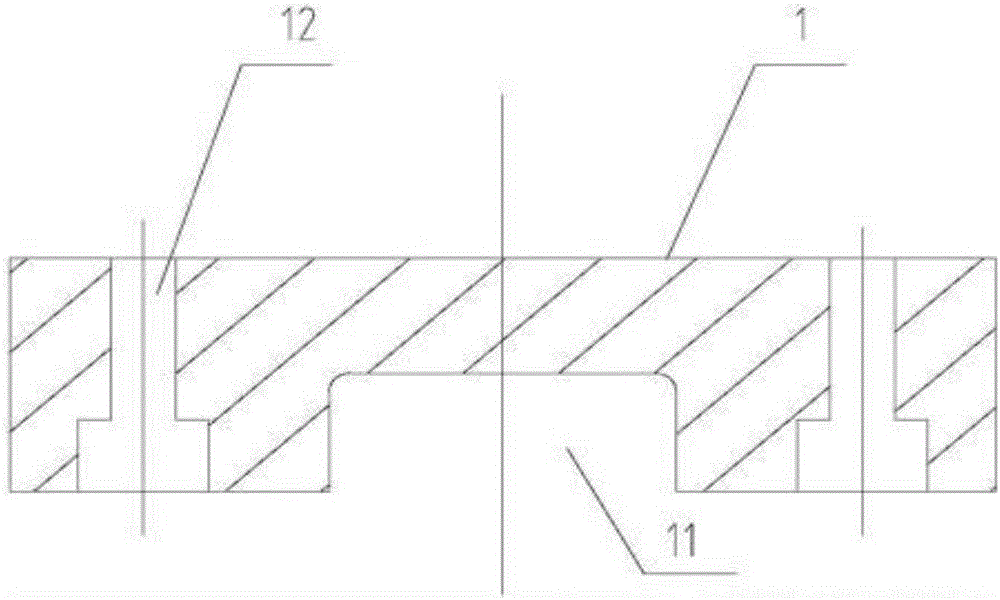

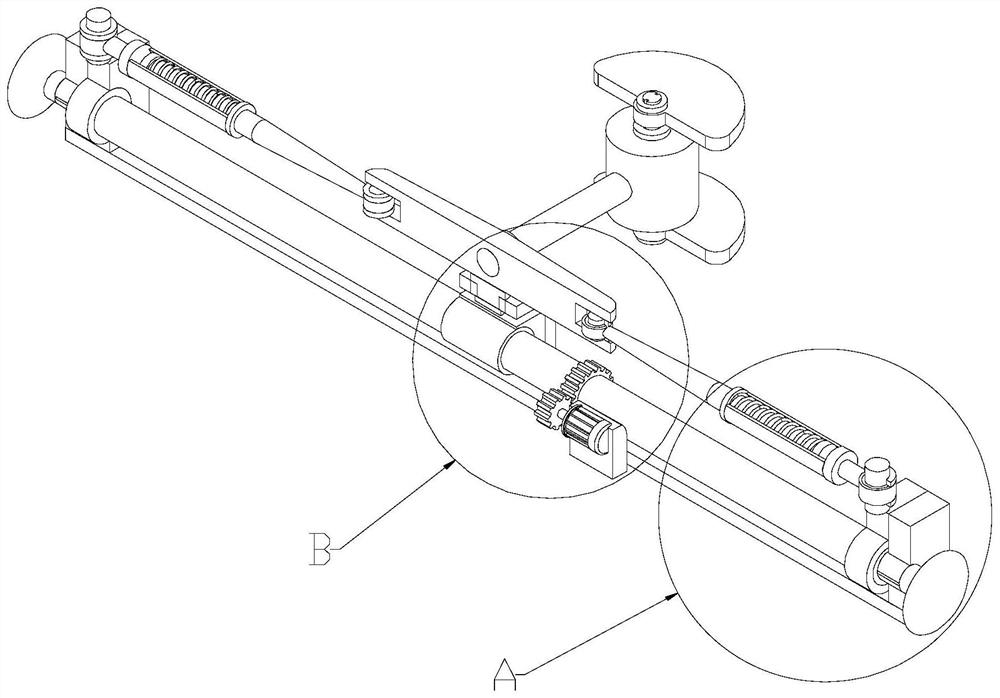

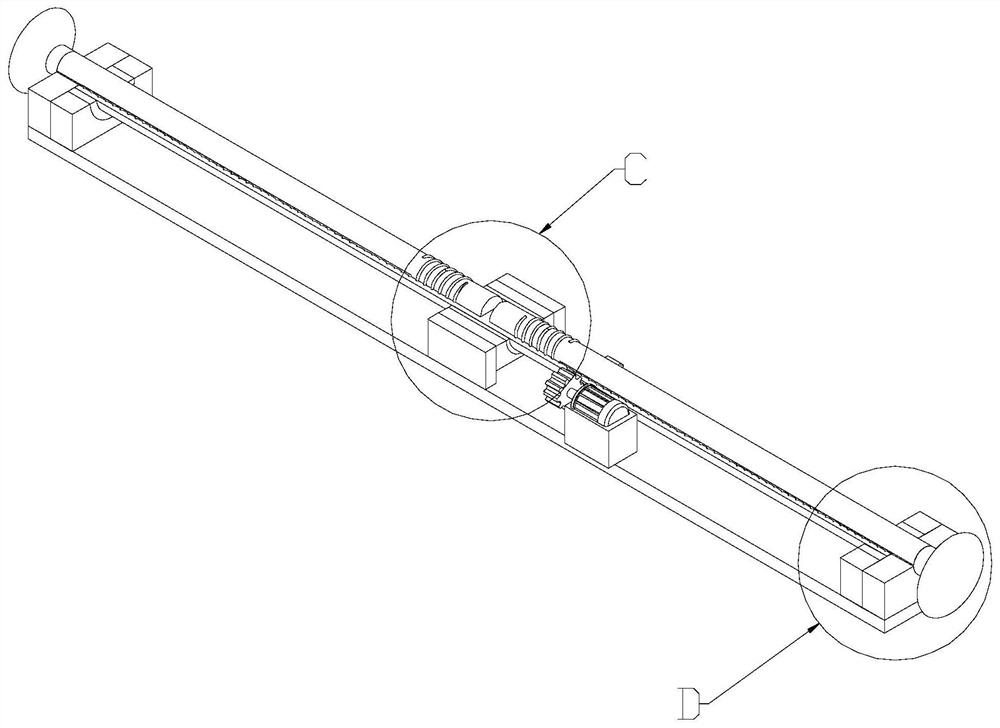

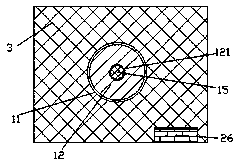

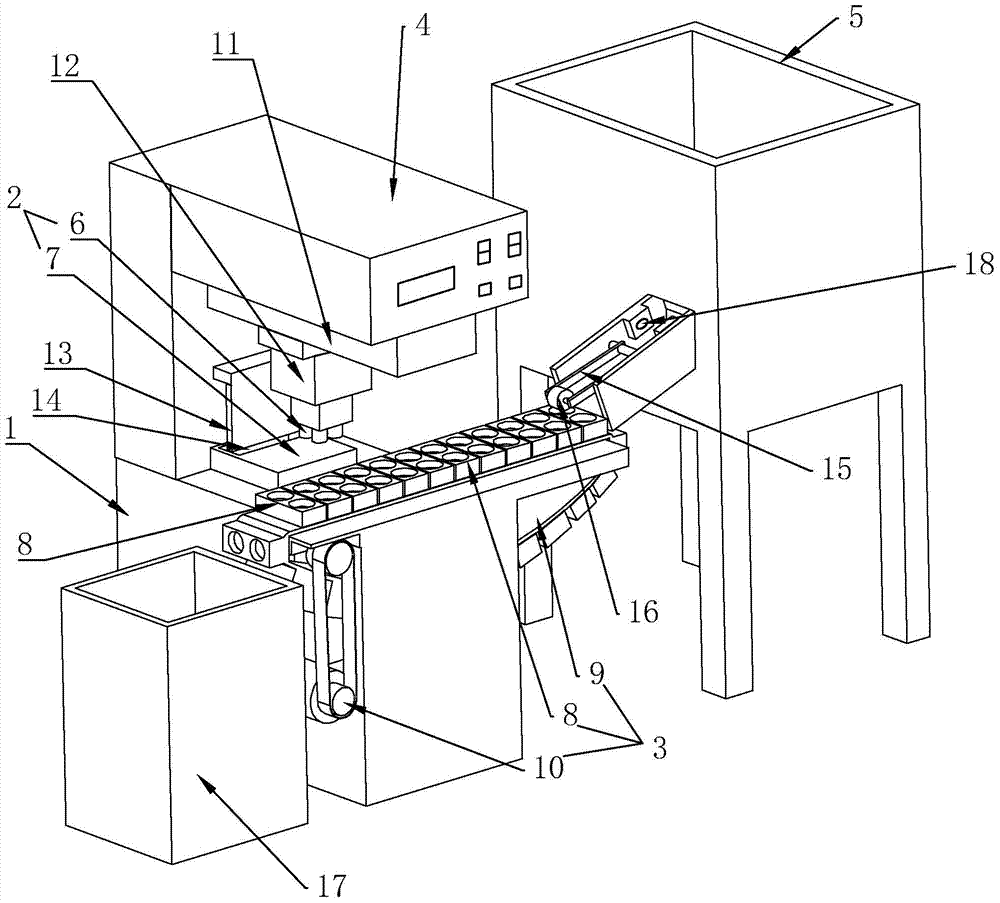

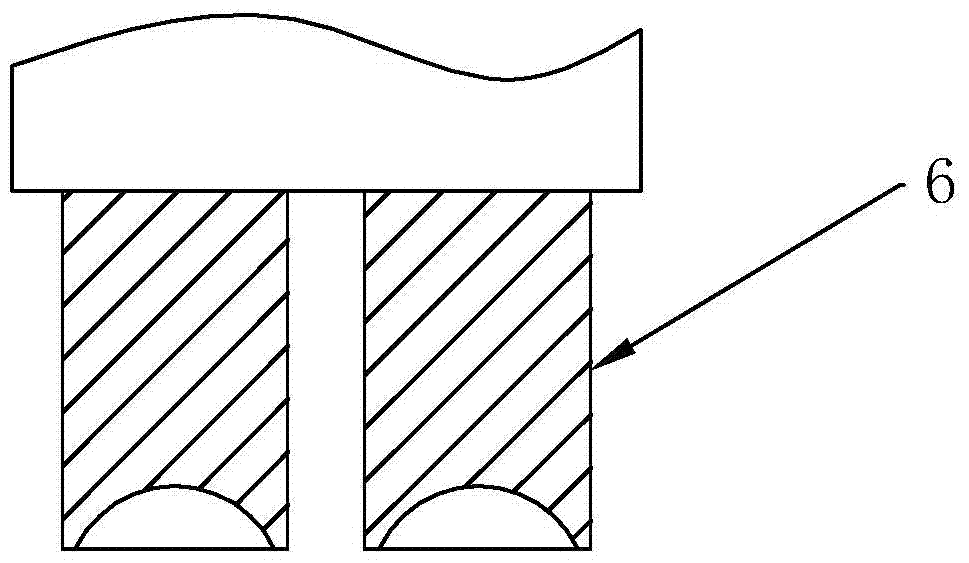

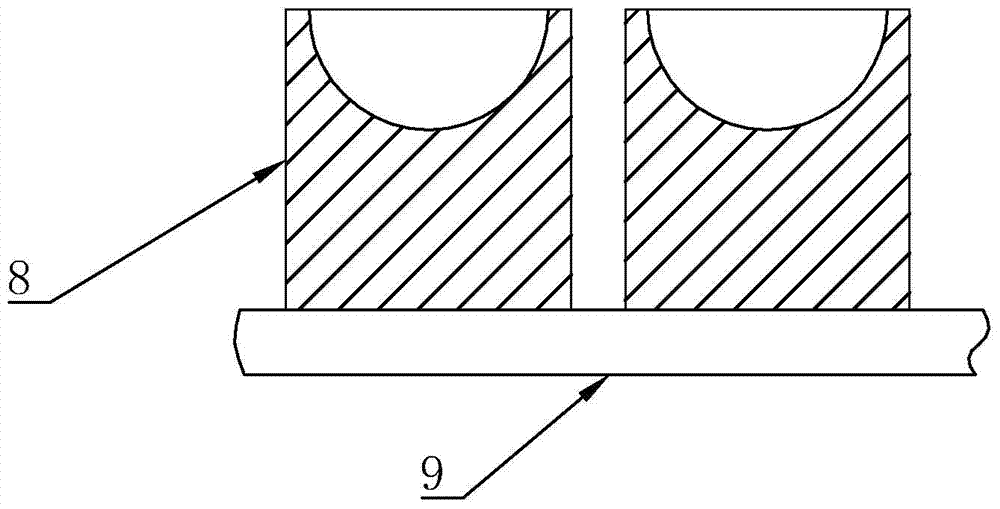

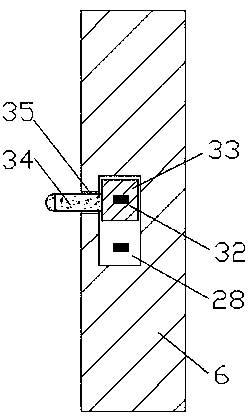

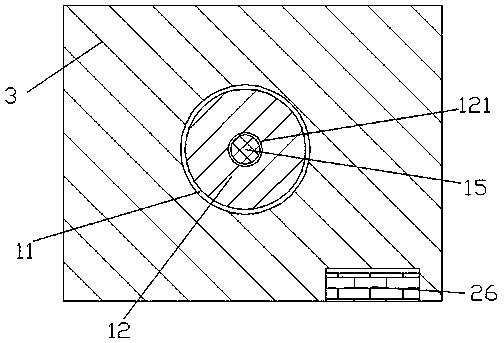

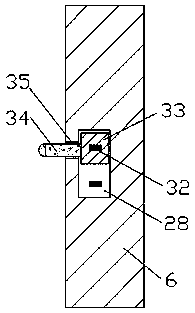

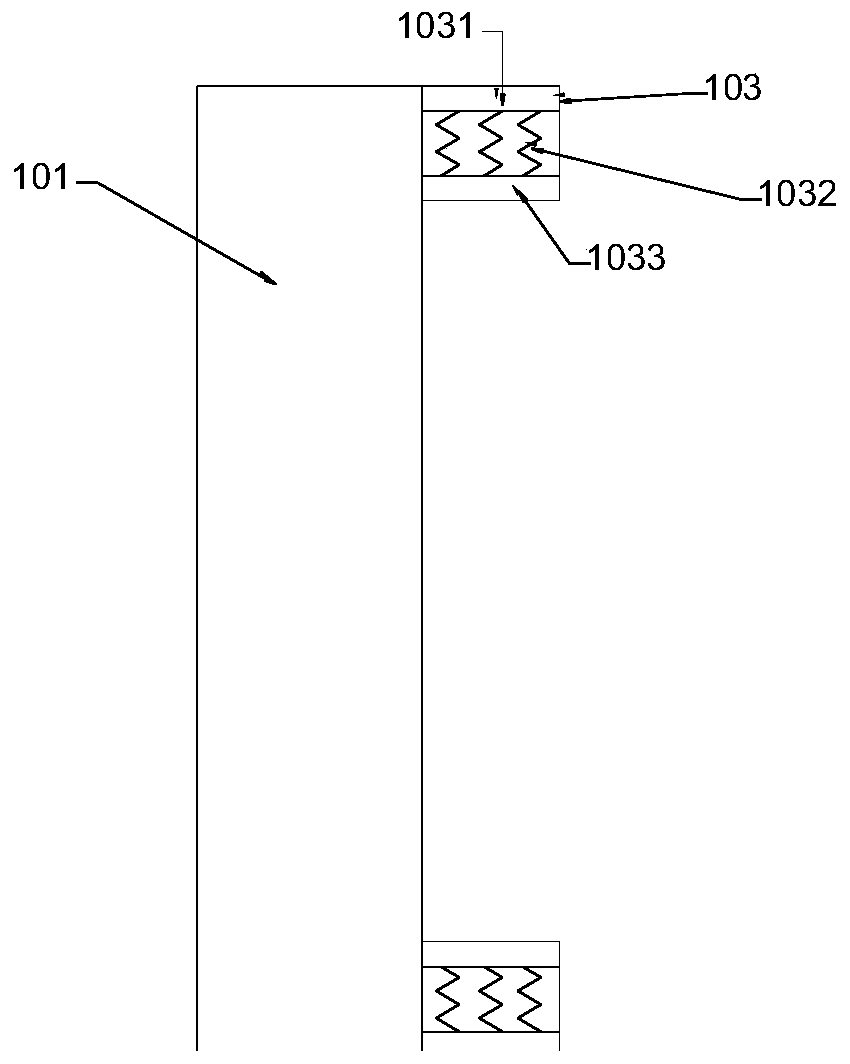

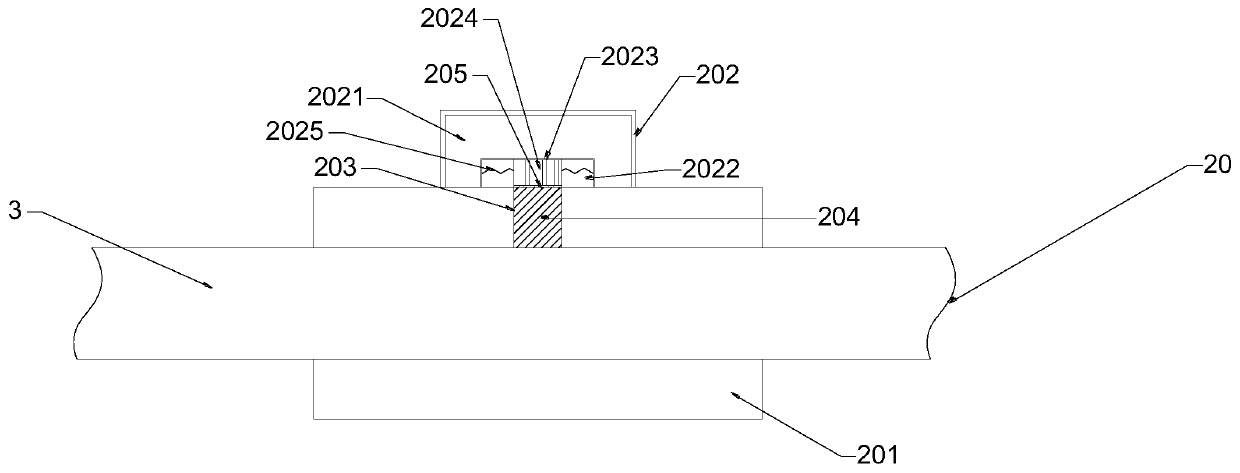

A table tennis marking printing machine

InactiveCN105667097BEasy to moveMobile stability ping pong does not occurTypewritersOther printing apparatusTrademarkTennis ball

The invention discloses a table tennis ball trademark printing machine. The key point of the technical scheme of the table tennis ball trademark printing machine lies in that the machine comprises a machine body, a printing device disposed at the upper end of the machine body, a feeding device arranged at the lower end of the machine body and matched with the printing device, a control box mounted on the machine body and used for controlling the printing device and the feeding device, a storage box mounted on the machine body and matched with the feeding device, and a collecting box disposed on the machine body. By means of the table tennis ball trademark printing machine, trademarks can be automatically printed onto table tennis balls, moreover the table tennis balls can be automatically discharged and collected, the manpower cost is reduced, and the production efficiency is improved.

Owner:浙江曙光体育用品有限公司

Novel civil aviation engine and important component equipment

InactiveCN108526850AEnsure consistencyMovement does not occurUsing optical meansMetal working apparatusSignal lightHandrail

The invention discloses a novel civil aviation engine and important component equipment. The novel civil aviation engine comprises a fixing base, wherein foot columns are fixedly arranged around the bottom surface of the fixing base, rolling wheels are arranged at the bottom parts of the foot columns, a pushing armrest is fixedly arranged on the left end surface of the fixing base, a lower machinebody is fixedly connected onto the upper end surface of the fixing base, an upper machine body is arranged on the upper side of the lower machine body, an operation part is arranged between the uppermachine body and the lower machine body, a left supporting plate and a right supporting plate are respectively arranged at both the left end and the right end of the operation part, a lower seat block is fixedly connected onto the upper end surface of the lower machine body rotationally, an upper seat block is fixedly connected onto the lower end surface of a limiting plate, a display screen is fixedly arranged on the right side of the front end surface of the upper machine body, a signal light is fixedly connected to the right side of the upper end surface of the upper machine body, and an electronic ruler is fixedly connected to the left side of a landing block. In the operation, the electronic ruler can measure different gap values of one revolution of a workpiece, and after being processed by a system, specific values are displayed, and when the gap values are too large, the display screen controls the signal light to work.

Owner:GUANGZHOU JUMING AUTO CONTROL TECH CO LTD

A trademark printer for ping pong balls

InactiveCN105459616BEasy to moveMobile stability ping pong does not occurTypewritersOther printing apparatusTrademarkEngineering

The invention discloses a trademark printing machine used for a table tennis ball body. According to the technical scheme, the trademark printing machine comprises a machine body, a printing device arranged at the upper end of the machine body, a feeding device arranged at the lower end of the machine body and matched with the printing device, a control box arranged on the machine body and used for controlling the printing device and the feeding device, a storage box arranged on the machine body and matched with the feeding device, and a collecting box arranged on the machine body. The trademark printing machine used for the table tennis ball body can be used for automatically printing a trademark on the table tennis ball body, the table tennis ball body can be automatically unloaded and collected, labor cost is saved, and production efficiency is improved.

Owner:浙江曙光体育用品有限公司

Novel digital design manufacturing device

InactiveCN108469227AMovement does not occurEnsure consistencyUsing optical meansMetal-working hand toolsEngineeringWork zone

The invention discloses a novel digital design manufacturing device comprising a fixed base plate; the top end face of the fixed base plate is fixedly connected with a lower machine board; an upper machine board is arranged on the lower machine board; the upper and lower machine boards clamp to form a work zone; the left and right ends of the work zone are respectively provided with a left supportplate and a right support plate; the top end face of the lower machine board is rotatably fixedly connected with a lower fixed block; the bottom end face of a limit plate is fixedly connected with anupper fixed block; an integrated display panel is embedded on the right side of the front end face of the upper machine board; an alarm lamp is fixedly connected on the right side of the top end faceof the upper machine board; a laser caliber is fixedly connected on the left side of an elevation block. In usage, the laser caliber can measure different gap values of a workpiece rotating in one circle, and specific values can be displayed after being processed by the system; when the gap value is too big, the integrated display panel controls the alarm lamp to work; datamation application is realized, thus preventing unclear disputes caused by artificial factors.

Owner:广州曙迅自动化设备有限公司

Novel precise-forming manufacturing device

InactiveCN108406266AMovement does not occurEnsure consistencyMetal working apparatusEngineeringDistance measuring equipment

The invention discloses a novel precise-forming manufacturing device comprising a seat body. Supporting columns are fixedly arranged on the four corners of the bottom face of the seat body, and suction cups used for being sucked on the ground are fixedly arranged on the bottom faces of the supporting columns. A lower plate body is fixedly connected to the upper end face of the seat body, an upperplate body is arranged on the upper side of the lower plate body, and a cavity part is formed between the upper plate body and the lower plate body. A left supporting plate and a right supporting plate are arranged at the left end and the right end of the cavity part correspondingly. The upper end face of the lower plate body is rotationally and fixedly connected with a lower fixed connection block; the lower end face of a clamping-limiting plate is fixedly connected with an upper fixed connection block; an electronic screen is fixedly arranged on the right side of the front end face of the upper plate body; the right side of the upper end face of the upper plate body is fixedly connected with a flasher; and the left side of a rising and falling block is fixedly connected with distance measuring equipment. During working of the novel precise-forming manufacturing device, the distance measuring equipment can measure different gap values in the process that a workpiece rotates by a circle, specific numerical values are displayed after the gaps values are processed by a system, and when the gap values are overlarge, the electronic screen controls the flasher to work.

Owner:佛山诗勤智能科技有限公司

An automated CNC machine tool

ActiveCN108907720BReduce vibrationNo offsetOther manufacturing equipments/toolsNumerical controlElectric machinery

The invention belongs to the technical field of numerically-controlled machine tools, and provides an automatic numerically-controlled machine tool. The automatic numerically-controlled machine tool comprises a machine tool; stand columns are arranged at the two ends of the machine tool, a transverse guide rail, a first lead screw and a first motor are arranged on the stand columns, the transverseguide rail is parallel to the first lead screw, and the first motor is connected to the first lead screw; a transverse moving platform is arranged on the transverse guide rail, the first lead screw is connected to the transverse moving platform through a nut, and a longitudinal guide rail, a second lead screw and a second motor are arranged on the transverse moving platform; and a longitudinal moving platform is arranged on the longitudinal guide rail, the second lead screw is connected to the longitudinal moving platform through a nut, a clamping device used for fixing a workpiece is arranged on the longitudinal moving platform, and the second motor is connected to the second lead screw. The technical problems that in existing traditional multi-shaft drilling and tapping, if a drill jigguider is not adopted, the hole position degree deviation is large, a screw tap is prone to being damaged, and then a workpiece is scrapped; and if the drill jig guider is adopted, secondary clampingerrors exist and automatic machining is inconvenient to achieve due to technology reasons are solved.

Owner:高邑县云发专用机床厂

Precise-forming manufacturing device

InactiveCN108406267AMovement does not occurEnsure consistencyMetal working apparatusEngineeringDistance measuring equipment

The invention discloses a precise-forming manufacturing device comprising a seat body. Supporting columns are fixedly arranged on the four corners of the bottom face of the seat body, and suction cupsused for being sucked on the ground are fixedly arranged on the bottom faces of the supporting columns. A lower plate body is fixedly connected to the upper end face of the seat body, an upper platebody is arranged on the upper side of the lower plate body, and a cavity part is formed between the upper plate body and the lower plate body. A left supporting plate and a right supporting plate arearranged at the left end and the right end of the cavity part correspondingly. The upper end face of the lower plate body is rotationally and fixedly connected with a lower fixed connection block; thelower end face of a clamping-limiting plate is fixedly connected with an upper fixed connection block; an electronic screen is fixedly arranged on the right side of the front end face of the upper plate body; the right side of the upper end face of the upper plate body is fixedly connected with a flasher; and the left side of a rising and falling block is fixedly connected with distance measuringequipment. During working of the novel precise-forming manufacturing device, the distance measuring equipment can measure different gap values in the process that a workpiece rotates by a circle, specific numerical values are displayed after the gap values are processed by a system, and when the gap values are overlarge, the electronic screen controls the flasher to work.

Owner:佛山诗勤智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com