Intelligent checkout stand for stamping parts

A technology for inspection benches and stamping parts, which is applied to workbenches, parts of lighting devices, lighting devices, etc., can solve problems such as no data analysis, insufficient inspection of stamping parts, and no historical records, so as to improve stability and accuracy performance, quality improvement, and ease of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The invention discloses an intelligent inspection platform for stamping parts, which is designed based on the deficiencies of poor lighting for stamping parts inspection, inadequate inspection of stamping parts, no historical records after stamping parts inspection, and no data analysis for stamping parts inspection An intelligent inspection platform for stamping parts, the invention can quickly analyze the cause of unqualified products through multi-angle inspection, good lighting environment, historical data inspection records and inspection analysis, and provide corresponding solutions. Good inspection bench for piece inspection.

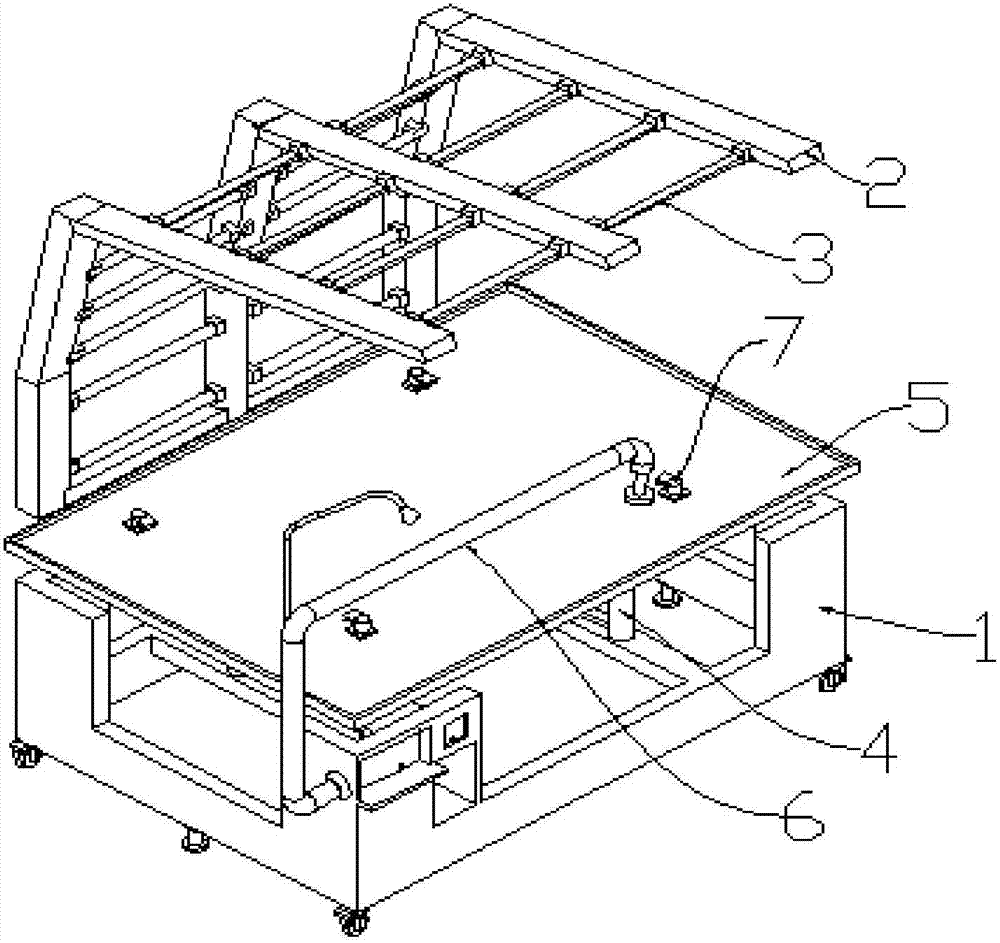

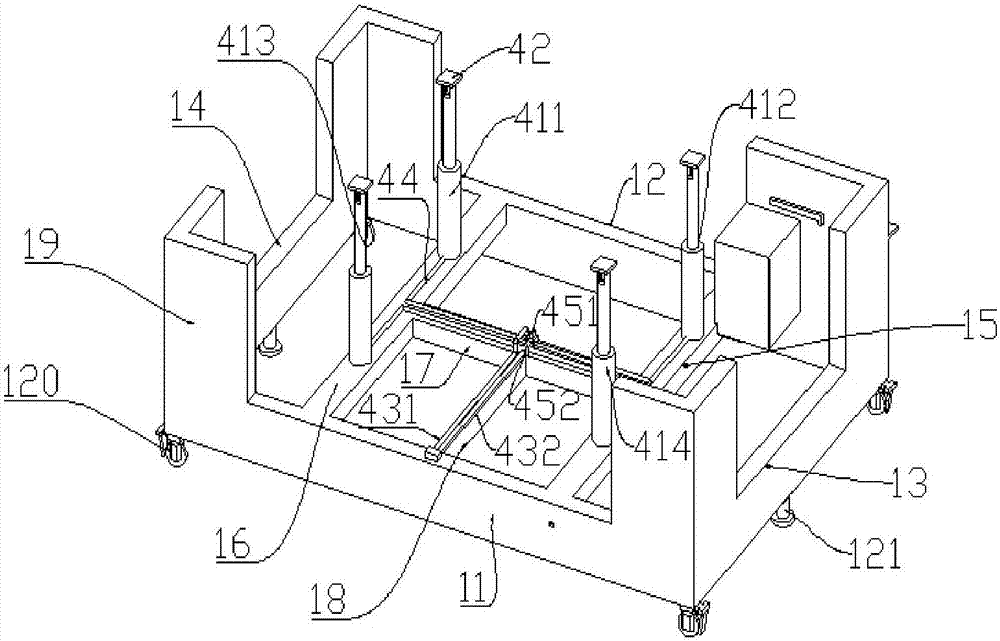

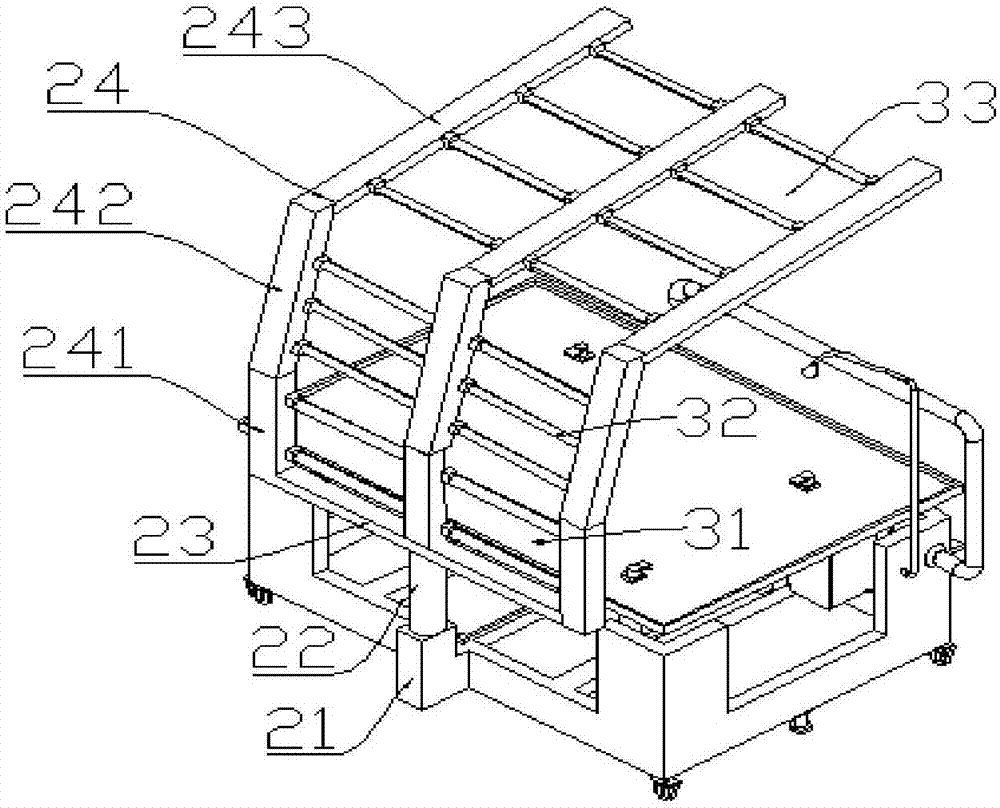

[0029] See how figure 1 and Figure 4 , an intelligent inspection platform for stamping parts, including a chassis 1, a lamp holder 2, a lamp assembly 3, a lifting device 4, an inspection platform 5 and a scanning system 6, and the rear side of the chassis 1 is provided with a rotatable The lamp stand 2, the lamp tube assembly 3 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com