Paper board conveyor and use method thereof

A conveyor and cardboard technology, used in transportation and packaging, thin material handling, function indication, etc., can solve the problems of low equipment transmission production efficiency, occupying production workshops, and cardboard falling off, so as to improve contact stability and improve production efficiency. , the effect of avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

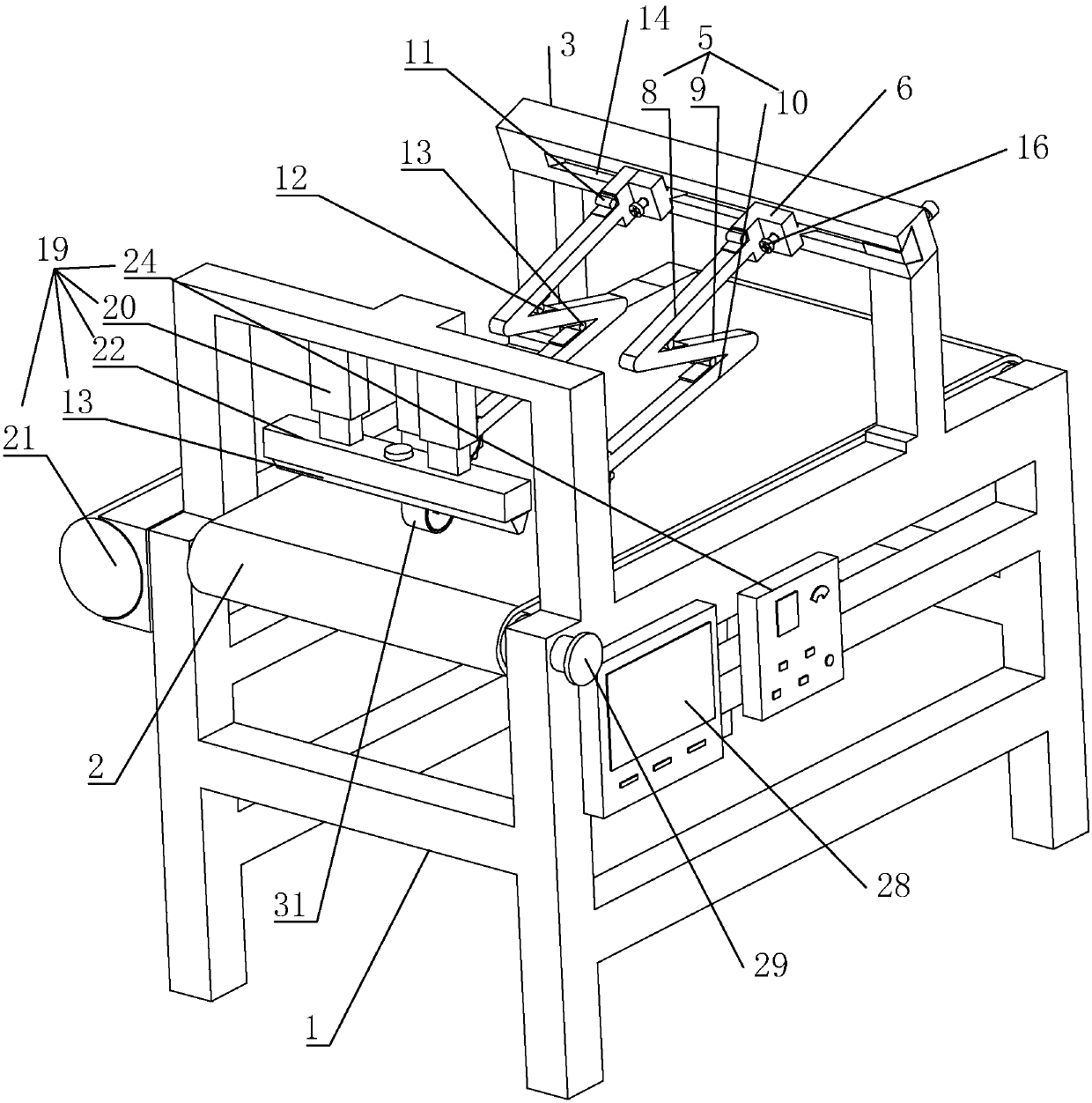

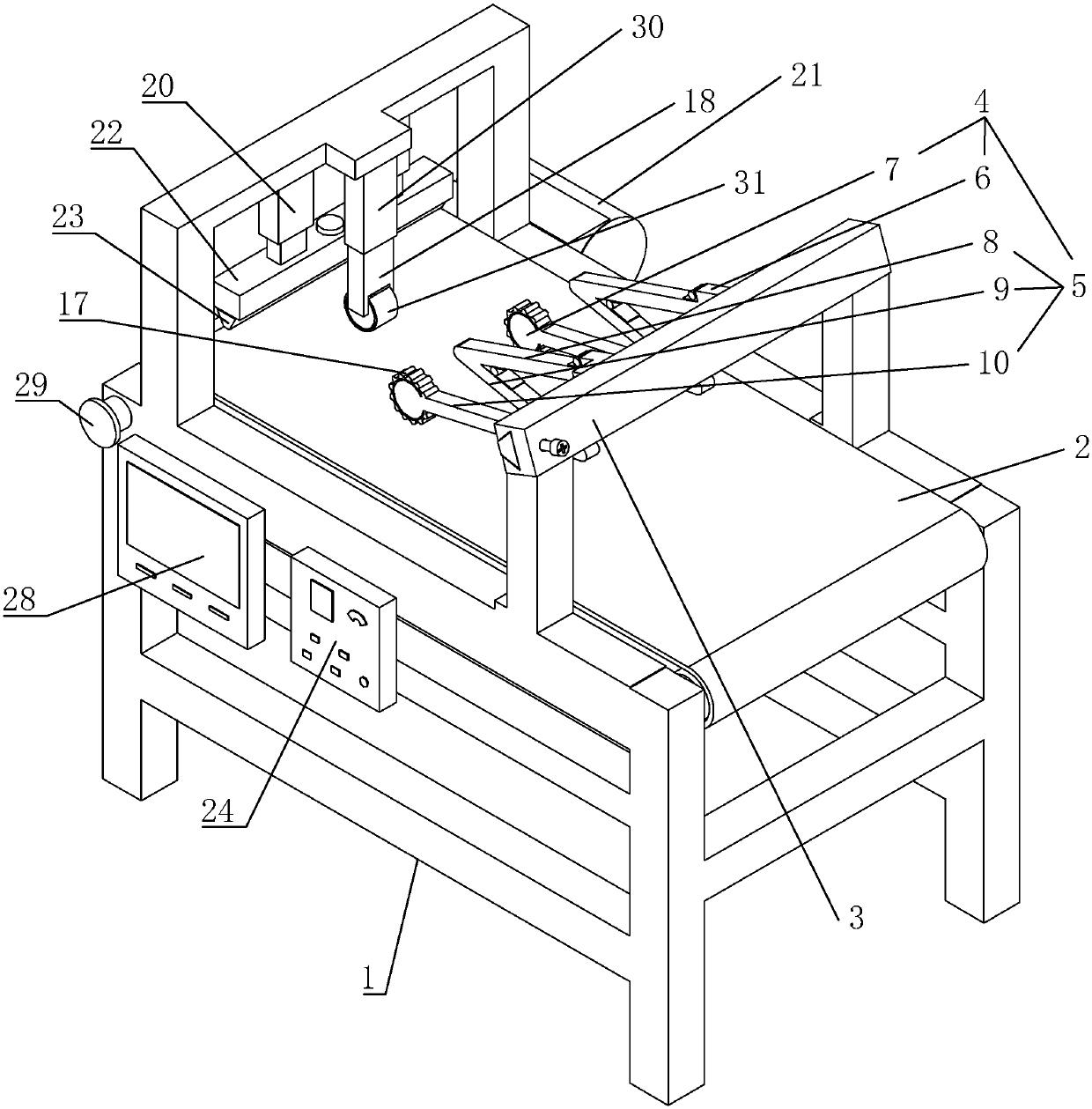

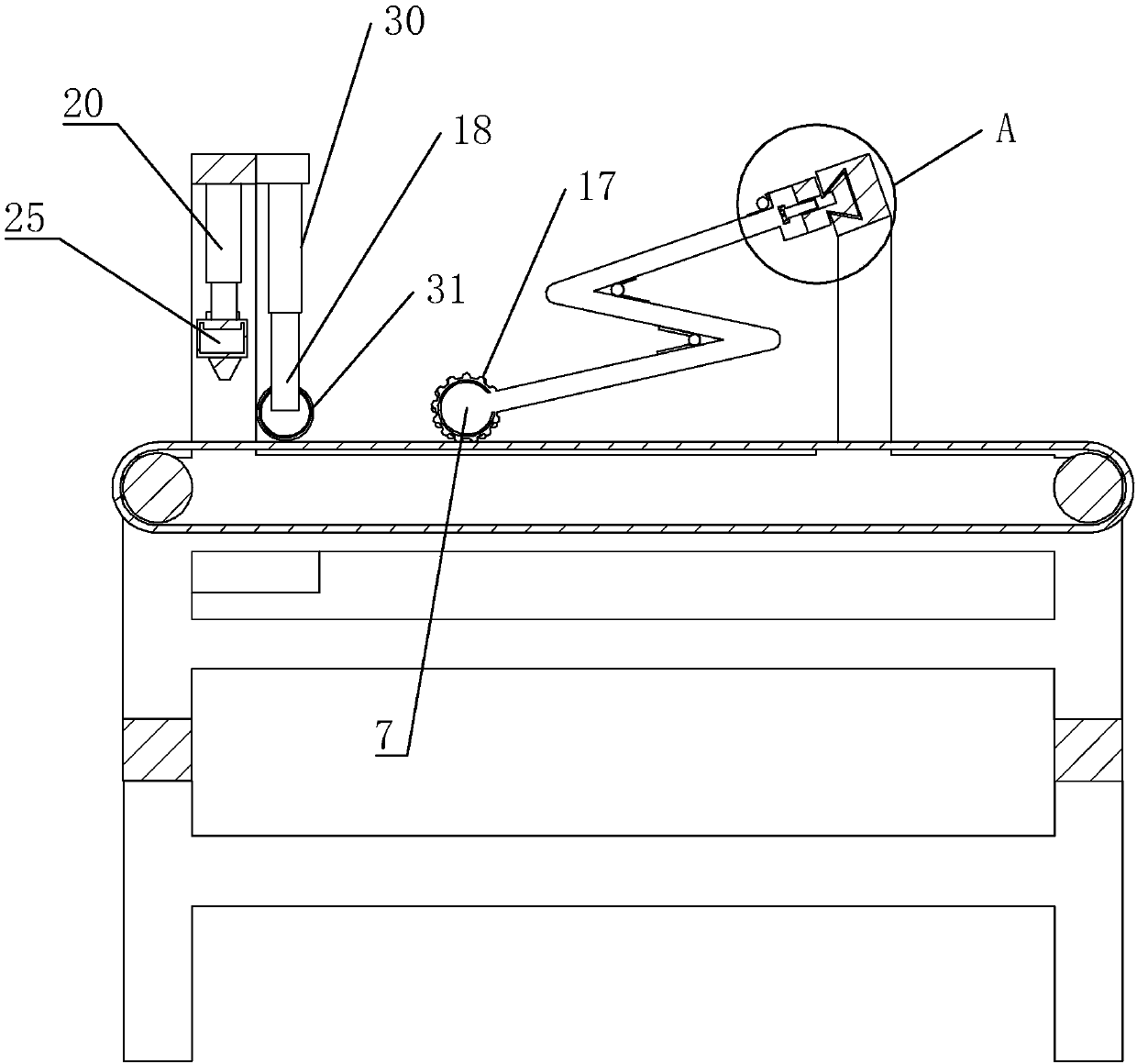

[0036] refer to Figures 1 to 5 As shown, a kind of cardboard conveyor of the present embodiment includes a frame 1 and a conveyor belt 2 arranged on the frame 1. The frame 1 is provided with a bracket 3 located on the upper side of the conveyor belt 2, so that The support 3 is provided with a pressing device 4 that is in contact with the surface of the conveyor belt 2. The pressing device 4 includes a pressing rod 5, a slider 7 and a roller 7. The pressing rod 5 includes a first pressing rod 8, The second pressing rod 9 and the third pressing rod 10, one end of the first pressing rod 8 is rotatably mounted on the slide block 7, and the first pressing rod 8 is arranged towards the direction in which the conveyor belt 2 moves, and the second pressing rod One end of 9 is rotatably connected to the end of the first pressing rod 8 away from the slider 7, and the second pressing rod 9 is set against the direction in which the conveyor belt 2 moves, and one end of the third pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com