Diaphragm type long-travel unidirectional spring mechanism

A technology of spring mechanism and large stroke, which is applied in the direction of spring/shock absorber, mechanical equipment, shock absorber, etc., and can solve the problems of difficult design of elastic coefficient curve and small stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

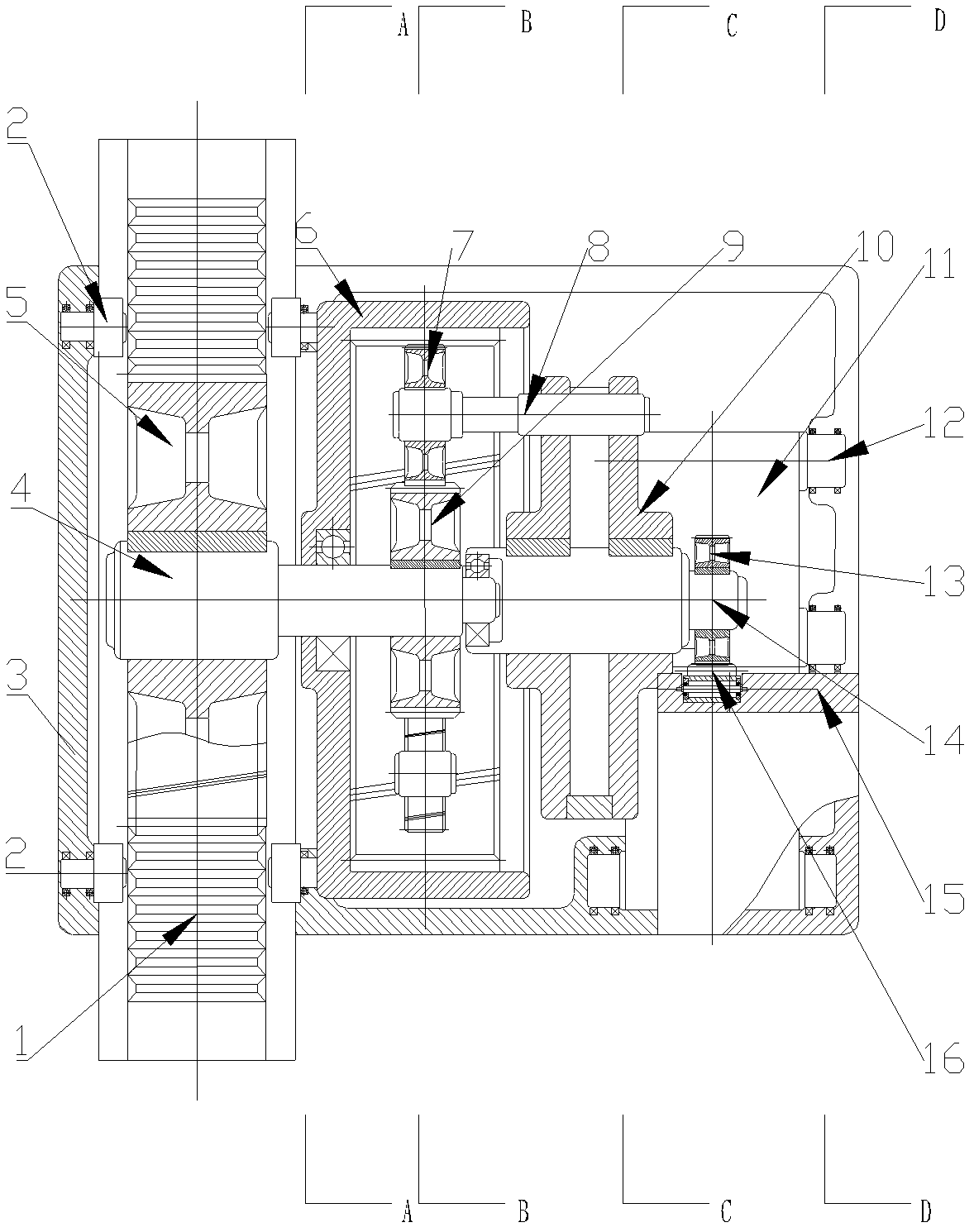

[0020] image 3 Instructions marked in: double-sided rack 1, double-sided rack guide roller 2, chassis 3, driving shaft 4, working gear 5, internal gear 6, planetary gear 7, planetary gear shaft 8, sun gear 9, planet carrier 10 , Ring-shaped film belt 11, cylinder 12, gear 13, driven shaft 14, cover plate 15, rack 16.

[0021] Figure 4 — Figure 7 Explanation of the middle mark: I key 17, II key 18, III key 19, guide roller 20, connector 21, screw rod 22, self-locking nut 23, and IV key 24.

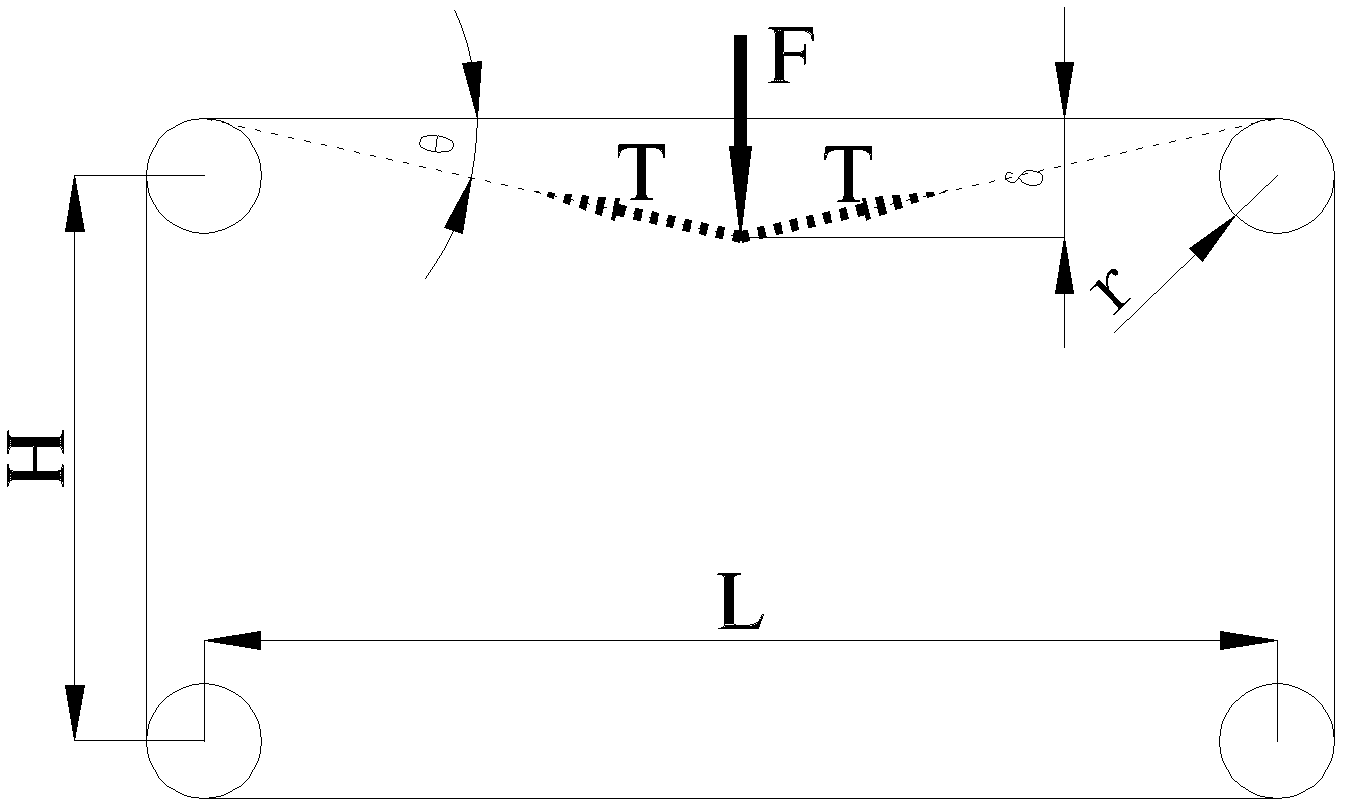

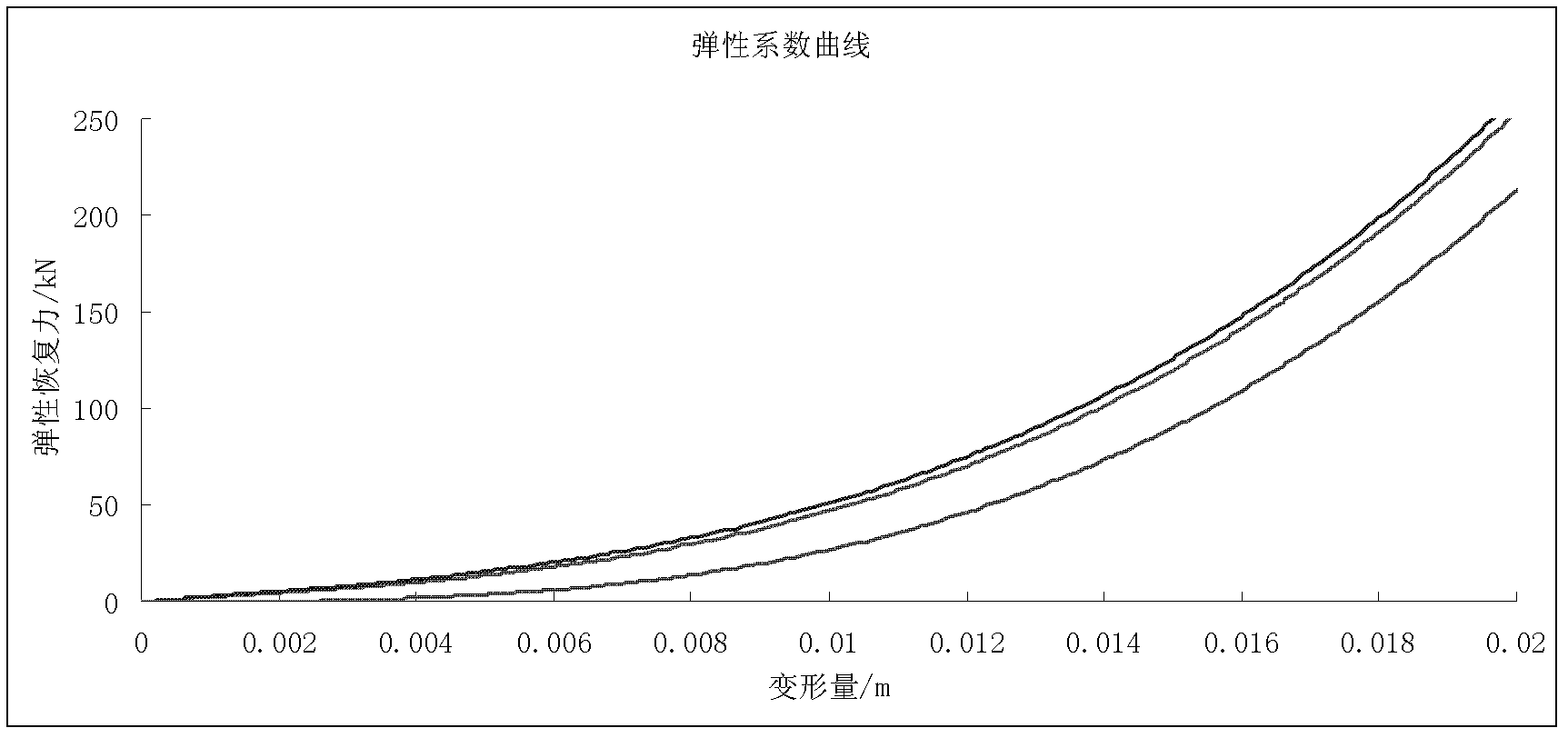

[0022] Invention principle: such as figure 1 As shown, under the action of external force F, the film belt supported by the cylinder is deformed, producing elastic restoring force. The relationship between the elastic recovery force and the transverse deformation δ of the film strip is:

[0023] 1

[0024] In the formula: T 0 is the initial tension on the film, A is the cross-sectional area of the film, E is the elastic modulus of the film, δ is the lateral deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com