Winding device

A technology of winding device and spool, applied in the field of mechanical processing, can solve the problems of excessive tension, excessive relaxation, affecting the winding process, etc., and achieve the effect of occupying a reasonable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

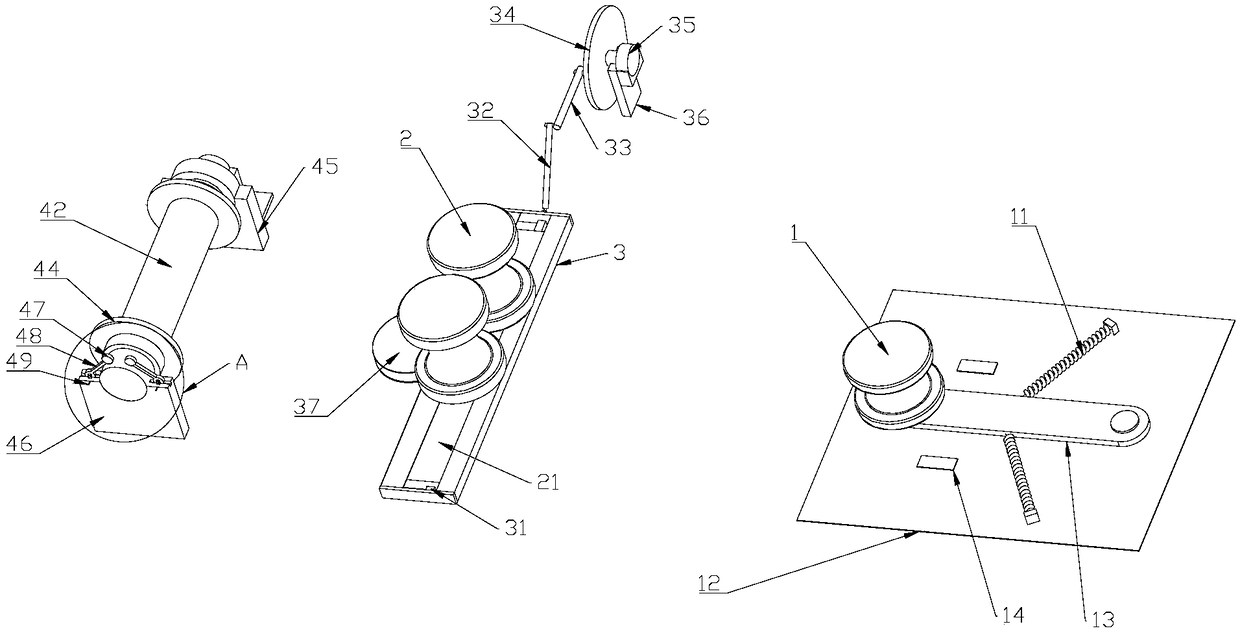

[0035] Such as figure 2 , A winding device, comprising a buffer wheel 1, a layer winding wheel 2 and a spool 4 arranged at intervals in sequence;

[0036] The buffer wheel 1 is arranged vertically, the bottom of the buffer wheel 1 is rotatably connected to one end of the buffer rod 13, and the other end of the buffer rod 13 is hinged to the buffer frame 12; both sides of the buffer rod 13 are respectively connected to the buffer spring 11 , The other side of the buffer spring 11 is connected to the buffer frame 12;

[0037] Two vertically arranged layer winding wheels 2 are arranged side by side. The bottom of the layer winding wheel 2 is rotatably connected to an adjusting rod 21, and the adjusting rod 21 is movably connected to the reciprocating seat 3, and the reciprocating seat 3 is provided with an adjusting wheel 23. The outer peripheral wall of the adjusting wheel 23 is provided with teeth 22, and the adjusting rod 21 and the adjusting wheel 23 are provided with a rack 24 t...

Embodiment 2

[0043] Such as figure 2 , image 3 with Figure 4 On the basis of including embodiment 1, the spool 4 is arranged horizontally, the two ends of the spool 4 are respectively connected to the movable support 46 and the fixed support 45 in rotation, and the spool 4 at one end of the fixed support 45 is connected to the spool motor, so The spool motor is fixed on the spool motor base, and the spool motor base is connected to the fixing bracket 45.

[0044] Both ends of the spool 4 are provided with a movable support 46 and a fixed support 45 to facilitate the replacement of the fully wound spool 4; a spool motor is installed on one side of the fixed support 45, which plays a role in the stability of the equipment, and the production safety performance is higher than that of the movable support. 46 side.

[0045] The upper part of the movable support 46 is provided with a spool accommodating groove, the other end of the spool 4 is overlapped in the spool accommodating groove, and the ...

Embodiment 3

[0054] Such as figure 1 with figure 2 , On the basis of including embodiment 1, the buffer racks 12 on both sides of the buffer rod 13 are respectively provided with induction detectors 14.

[0055] When the wire tension is too tight or broken, the buffer frame 12 will over-rotate. In order to avoid safety accidents, an induction detector 14 is set at a suitable position. When a danger occurs, the induction detector 14 senses the buffer frame 12. Then stop operation and improve safety performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com