Carrying system for stereo garage

A technology of handling system and three-dimensional garage, applied in the field of handling system, can solve the problems of hidden safety hazards, shaking, low reliability, etc., and achieve the effect of friction resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

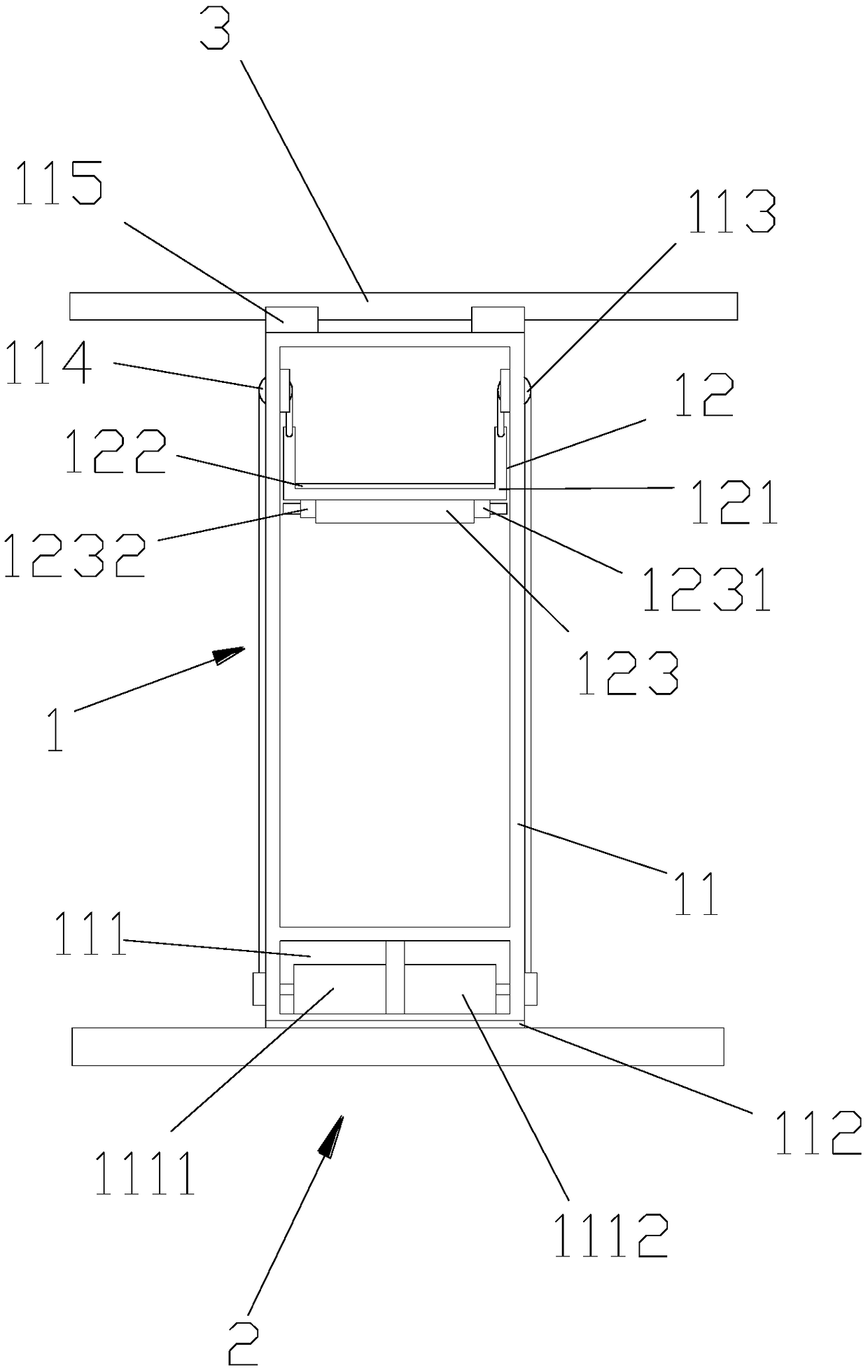

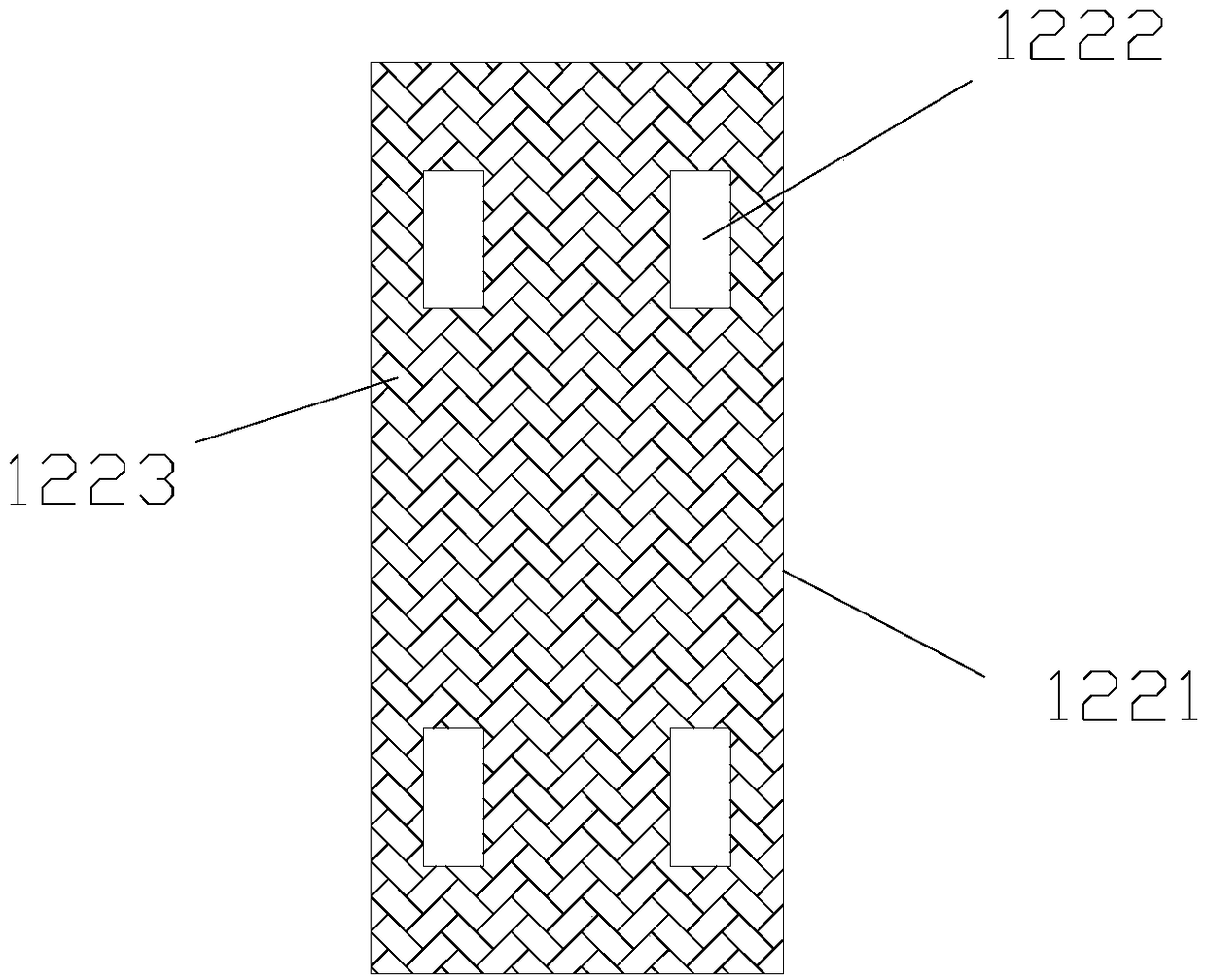

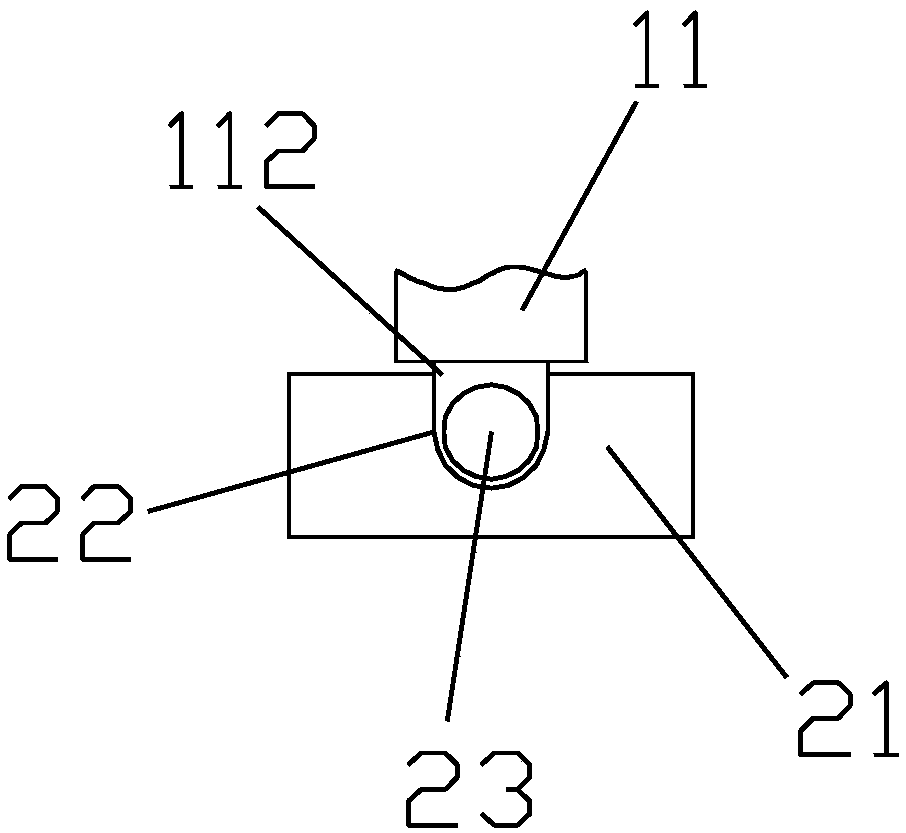

[0029] A handling system for three-dimensional garages, such as figure 1As shown, it includes a frame 1, and a rail seat 2 arranged at the bottom of the frame 1 and movably connected with the frame 1 for driving the sliding of the frame 1, and arranged at the top of the frame 1 and connected with the frame 1 The frame 1 is movably connected to the guide rail bar 3 used to transport the frame 1; the frame 1 includes a gantry frame body 11, and is arranged in the gantry frame body 11 and is suspended to be used for parking vehicles and conveying The bracket 12 of the vehicle; the lower end of the gantry body 11 is provided with a cavity frame 111, and the bottom of the cavity frame 111 is provided with a slide bar 112 integrally formed with the gantry body 11, and the gantry body 11 A first pulley 113 fixed with the gantry body 11 by screws is provided above one side, and a second pulley 114 fixed with the gantry body 11 by screws is provided above the other side of the gantry b...

Embodiment 2

[0040] A handling system for three-dimensional garages, such as figure 1 As shown, it includes a frame 1, and a rail seat 2 arranged at the bottom of the frame 1 and movably connected with the frame 1 for driving the sliding of the frame 1, and arranged at the top of the frame 1 and connected with the frame 1 The frame 1 is movably connected to the guide rail bar 3 used to transport the frame 1; the frame 1 includes a gantry frame body 11, and is arranged in the gantry frame body 11 and is suspended to be used for parking vehicles and conveying The bracket 12 of the vehicle; the lower end of the gantry body 11 is provided with a cavity frame 111, and the bottom of the cavity frame 111 is provided with a slide bar 112 integrally formed with the gantry body 11, and the gantry body 11 A first pulley 113 fixed with the gantry body 11 by screws is provided above one side, and a second pulley 114 fixed with the gantry body 11 by screws is provided above the other side of the gantry ...

Embodiment 3

[0051] A handling system for three-dimensional garages, such as figure 1 As shown, it includes a frame 1, and a rail seat 2 arranged at the bottom of the frame 1 and movably connected with the frame 1 for driving the sliding of the frame 1, and arranged at the top of the frame 1 and connected with the frame 1 The frame 1 is movably connected to the guide rail bar 3 used to transport the frame 1; the frame 1 includes a gantry frame body 11, and is arranged in the gantry frame body 11 and is suspended to be used for parking vehicles and conveying The bracket 12 of the vehicle; the lower end of the gantry body 11 is provided with a cavity frame 111, and the bottom of the cavity frame 111 is provided with a slide bar 112 integrally formed with the gantry body 11, and the gantry body 11 A first pulley 113 fixed with the gantry body 11 by screws is provided above one side, and a second pulley 114 fixed with the gantry body 11 by screws is provided above the other side of the gantry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com