Horizontal well re-fracturing method for tight oil reservoir

A technology for horizontal wells and tight oil, which is applied in the field of oil recovery in oil and gas fields. It can solve the problems of small oil increase and low recovery rate, and achieve the effects of increased oil increase effect, enhanced recovery rate, and reservoir energy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

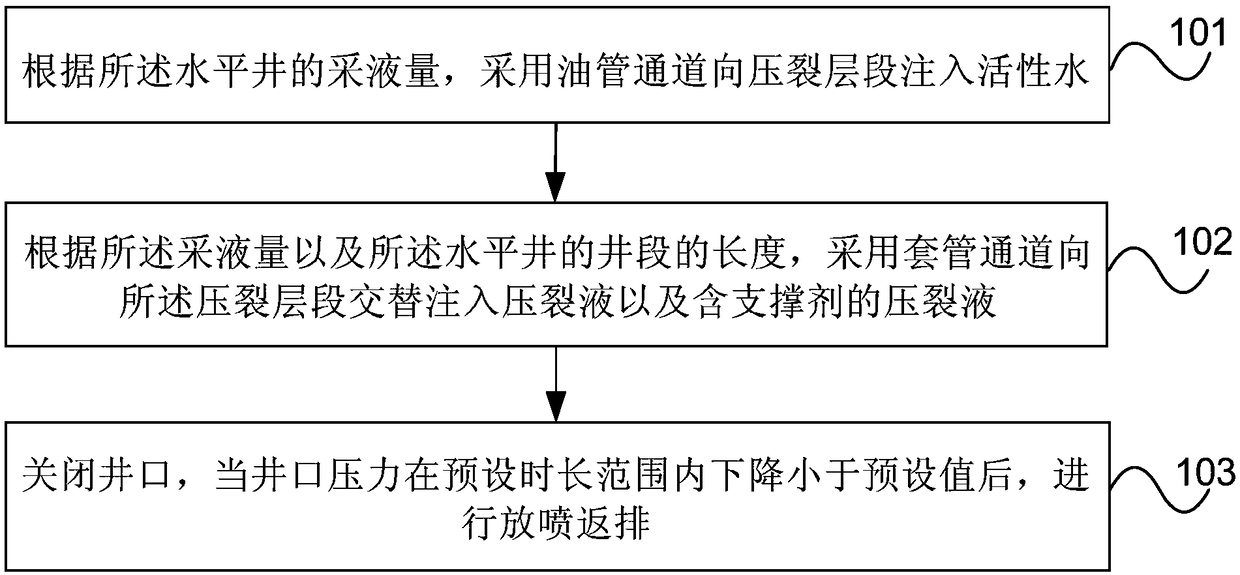

Method used

Image

Examples

example 1

[0076] Construction method: casing injection, general fracturing of combined layers.

[0077] Before fracturing, inject 13000m of active water according to 1.5 times of the previous liquid production volume 3 ;

[0078] Construction pressure limit: KQ70 / 65 type fracturing wellhead, casing head pressure 70, construction pressure limit 68Mpa, when the pressure reaches 65MPa, take measures to prevent the pressure from exceeding the limit pressure;

[0079] Fracturing construction: inject 2000m of fracturing fluid according to 0.23 times of the previous fluid production volume 3 . The liquid system adopts the whole slick water type fracturing fluid, the proppant adopts 40-70 mesh (52MPa) low-density ceramsite, and the total amount of proppant is 42m 3 .

[0080] The specific operation steps are as follows:

[0081] Step 1: After checking that all aspects of fracturing construction meet the quality and safety regulations, start formal construction according to the on-site comm...

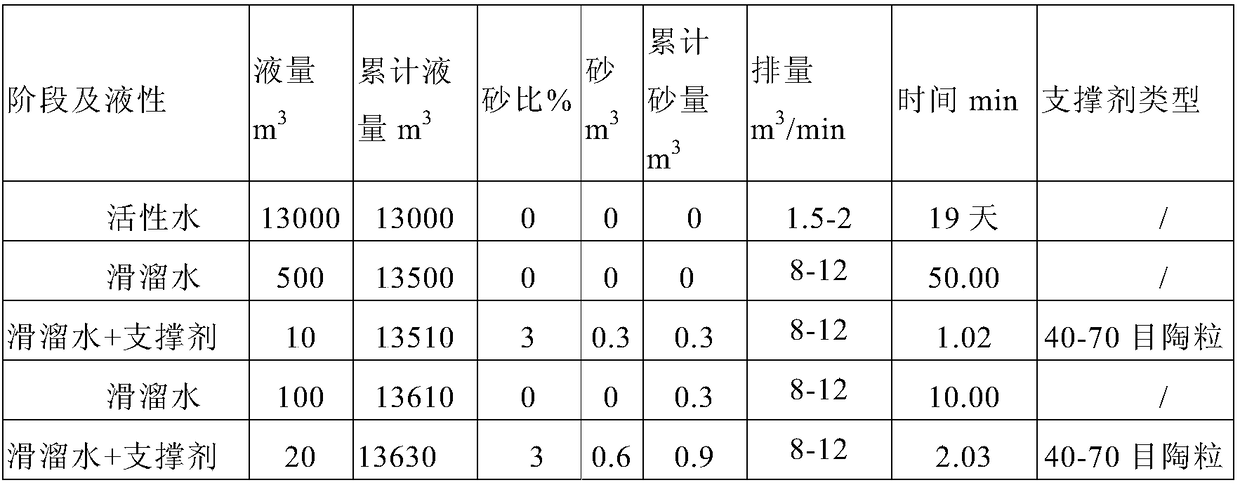

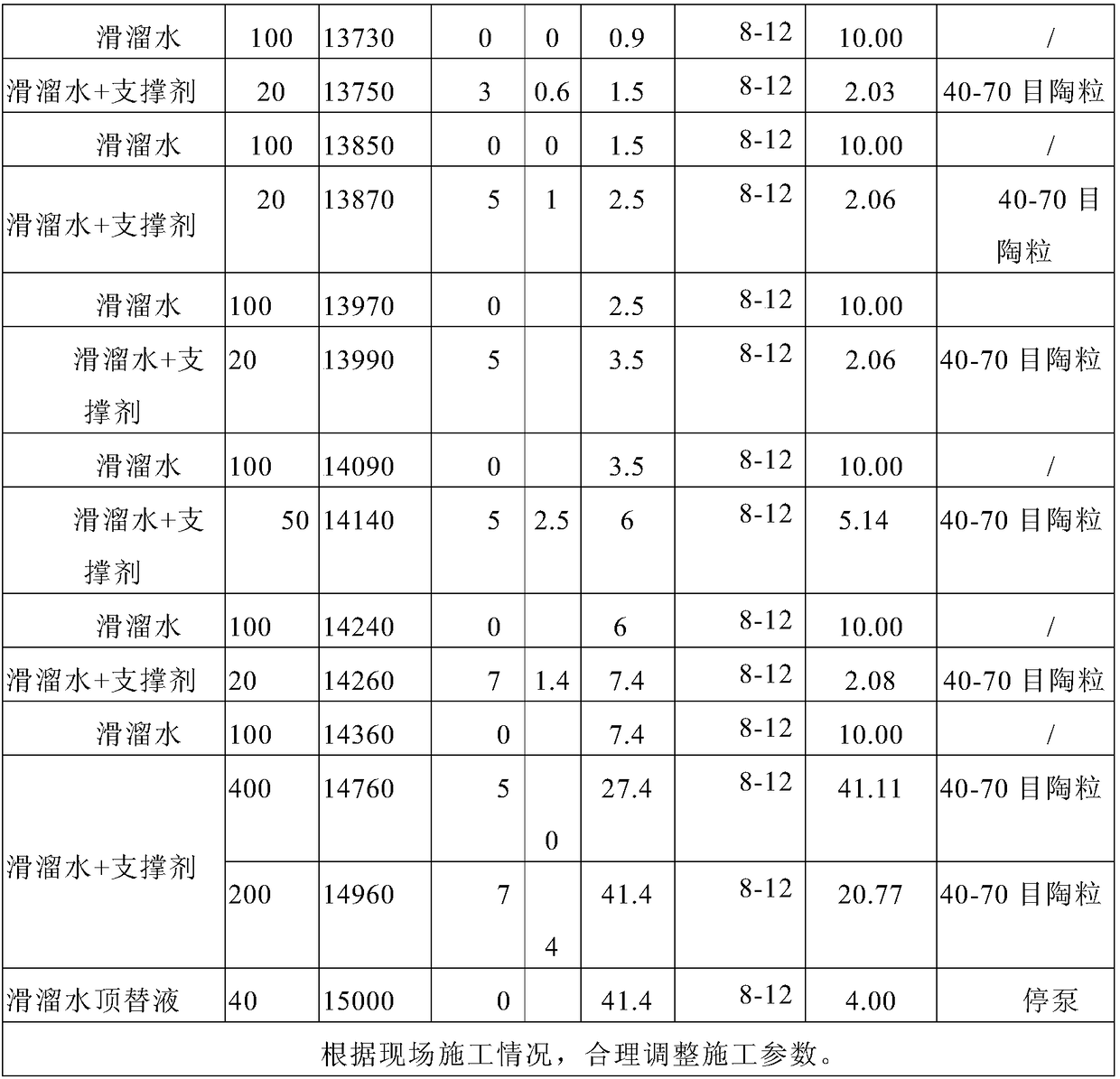

example 2

[0094] Construction method: casing injection, general fracturing.

[0095] Before fracturing, inject 15,000m of active water according to the requirements of the water injection energy enhancement process 3 ;

[0096] Construction pressure limit: KQ78-65 / 105 type fracturing wellhead, casing head pressure 105MPa, construction pressure limit 85MPa, when the pressure reaches 75MPa, take measures to prevent the pressure from exceeding the limit pressure;

[0097] Fracturing construction: inject 1000m of fracturing fluid 3 . The liquid system adopts full-range slippery water type fracturing fluid, and the proppant adopts 40-70 mesh (52MPa) low-density ceramsite, with a total volume of 28m 3 ;

[0098] The specific operation steps are as follows:

[0099] Step 1: After checking that all aspects of fracturing construction meet the quality and safety regulations, start formal construction according to the on-site command instruction;

[0100] Step 2: Pressure test of ground equi...

example 3

[0111] Construction method: casing injection, general fracturing.

[0112] Before fracturing, inject 8300m of active water according to the requirements of the water injection energy enhancement process 3 ;

[0113] Construction pressure limit: KQ130 / 78-105 type fracturing wellhead, construction pressure limit 85Mpa. The pressure test of the ground high-pressure pipeline is 85Mpa. When the pressure reaches 75MPa, take measures to prevent the pressure from exceeding the pressure limit;

[0114] Fracturing construction: inject 915m of fracturing fluid 3 . The liquid system adopts full-range slippery water type fracturing fluid, and the proppant adopts 40-70 mesh (52MPa) low-density ceramsite, with a total volume of 28m 3 ;

[0115] The specific operation steps are as follows:

[0116] Step 1: After checking that all aspects of fracturing construction meet the quality and safety regulations, start formal construction according to the on-site command instructions;

[0117]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com