Drying system with heat recovery function

A drying system and heat recovery technology, applied in the field of drying, can solve the problems of wasting social energy, heat dissipation, temperature drop, etc., and achieve the effect of saving social energy and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

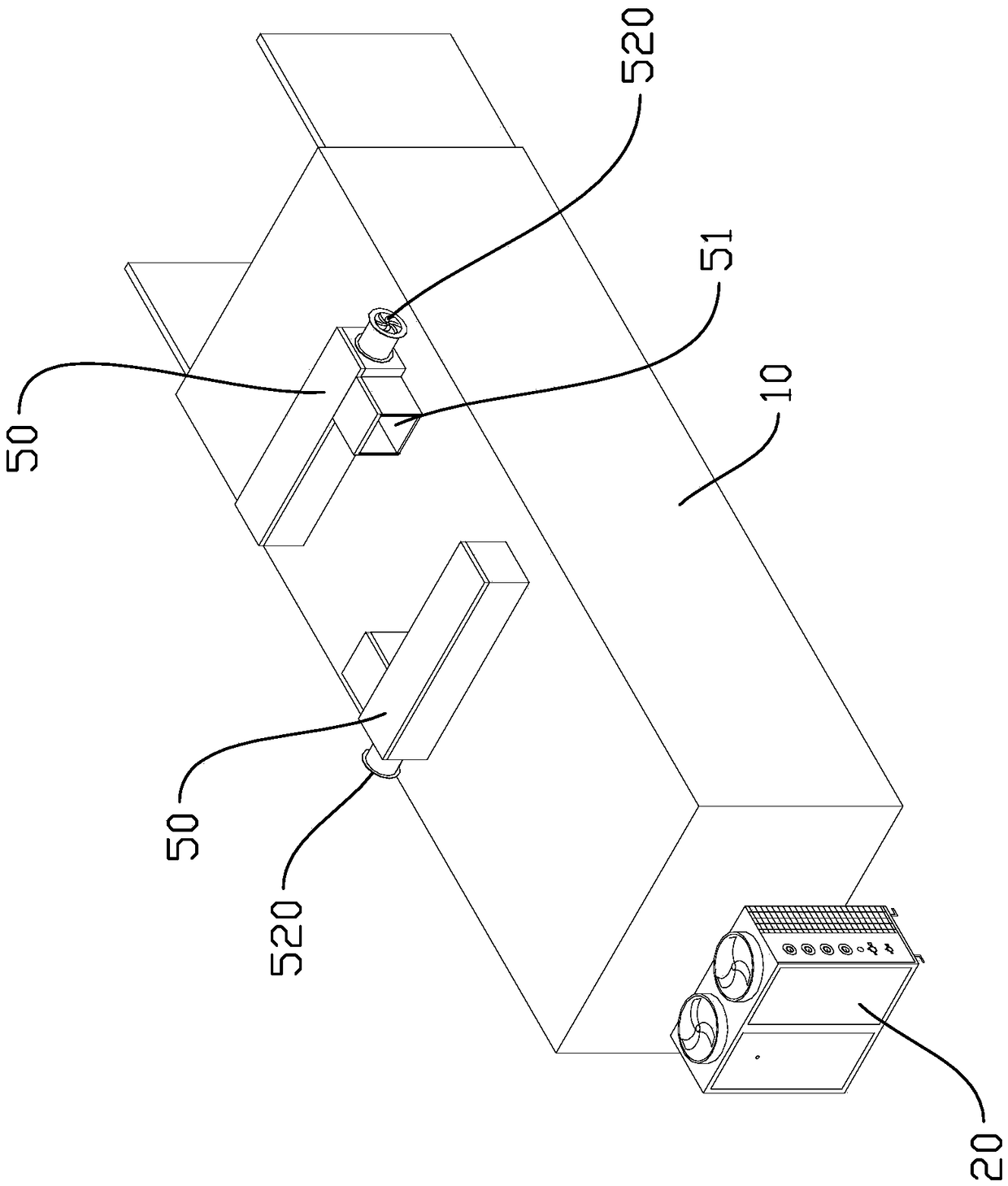

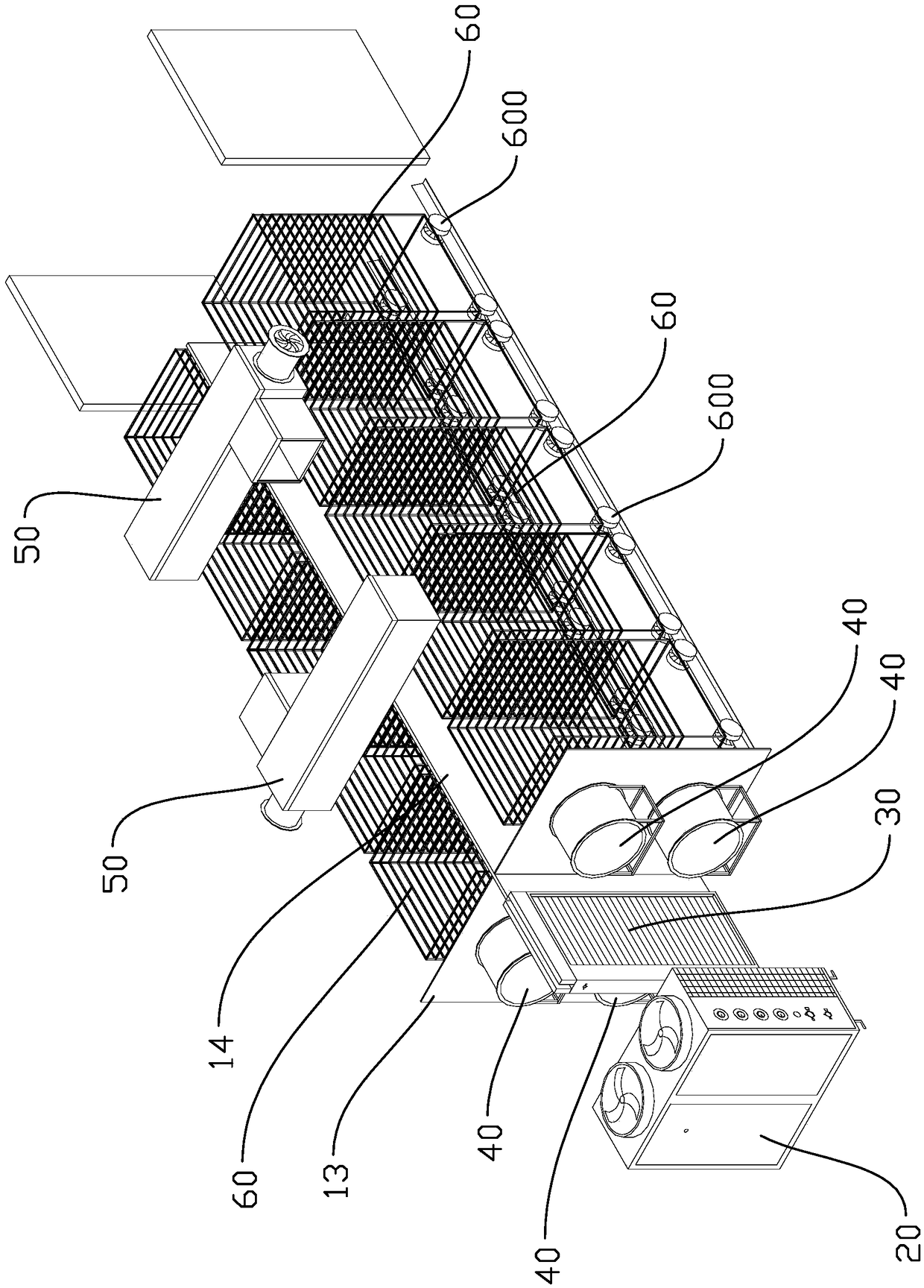

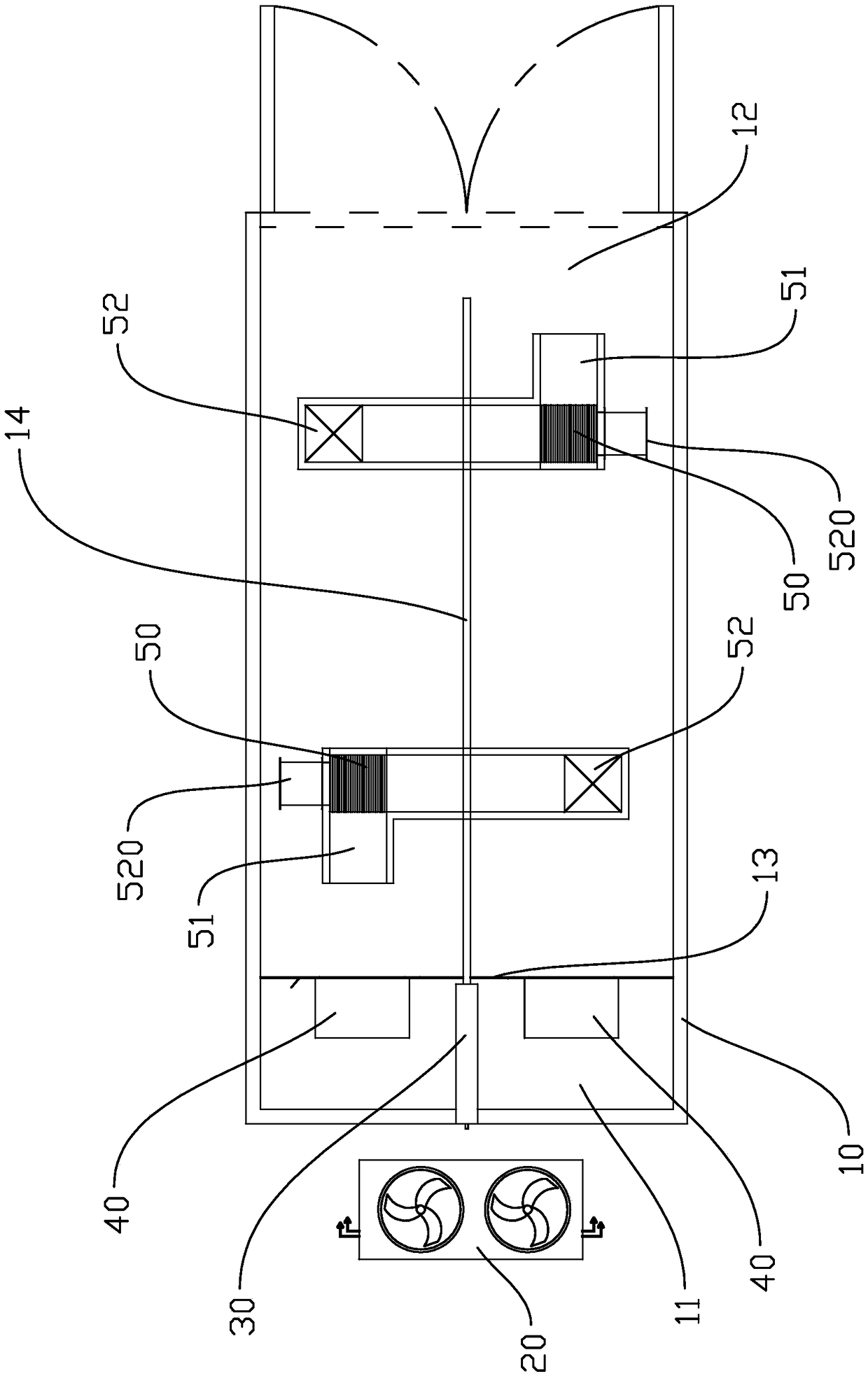

[0019] refer to Figure 1 to Figure 3 , a drying system with heat recovery function, comprising a drying room main body 10, the interior of the drying room main body 10 is hollow, and an outdoor unit 20 is arranged outside the drying room main body 10, and the outdoor unit 20 is connected to an indoor unit 30 located inside the main body 10 of the drying room through a refrigerant pipeline, and at least one indoor fan 40 is arranged inside the main body 10 of the drying room to accelerate the air flow inside it. The main body 10 of the drying room At least one heat recovery device 50 is provided on the top of the top, and the heat recovery device 50 is provided with an exhaust passage 52 and an air intake passage 51 that are independent of each other, and the exhaust passage 52 and the intake passage 51 are respectively connected to the drying oven. The house main body 10 is internally connected. Here, the heat recovery device 50 is a known technology in the art, and will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com