Air spring three-way composite loading fatigue test device and method

An air spring and compound loading technology, which is applied in the direction of measuring devices, testing of mechanical components, and testing of machine/structural components, can solve problems such as the inability to realize three-way compound loading fatigue tests, and improve test accuracy and reliability. , Improve the anti-rolling ability and reduce the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

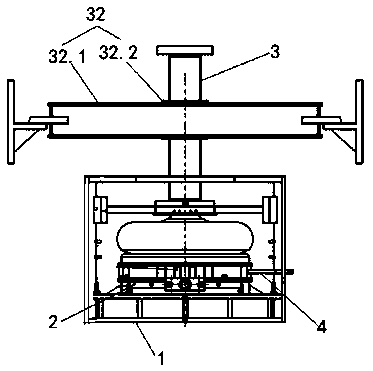

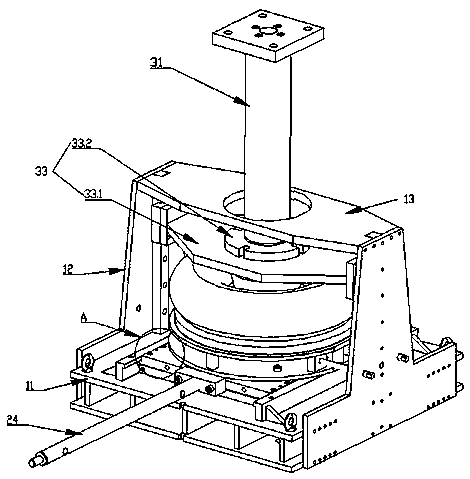

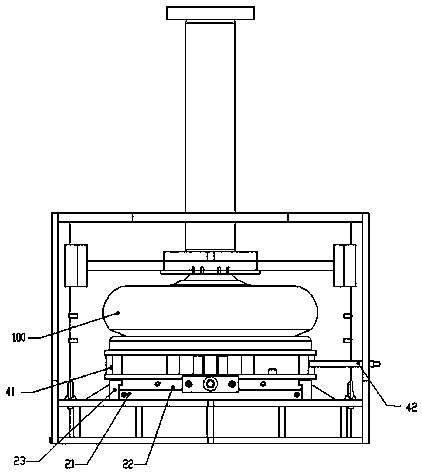

[0040] The following will be attached Figure 1~6 The present invention is further described with examples.

[0041]The air spring three-way composite loading fatigue test device includes a support 1, and is characterized in that it also includes a lateral loading assembly 2 for applying a lateral dynamic load to the air spring, and a vertical loading assembly for applying a vertical dynamic load to the air spring 3 and a longitudinal biasing assembly 4 for longitudinally deforming the air spring, the lateral loading assembly 2 is installed on the support 1 along the front and rear directions of the air spring, the longitudinal weaving assembly 4 is installed on the lateral loading assembly 2 and The positioning position on the lateral loading assembly 2 can be adjusted, the air spring is installed on the longitudinal bias assembly 4, and the vertical loading assembly 3 is arranged vertically directly above the air spring and contacts with the air spring.

[0042] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com