Vehicle engine water pump belt pulley test design method

A technology for a water pump pulley and an automobile engine, applied in the field of automobiles, can solve the problems of the failure of the water pump pulley and the inability to accurately reflect the fatigue performance of the water pump pulley, and achieve the effect of accurately reflecting the fatigue performance and avoiding insufficient test detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

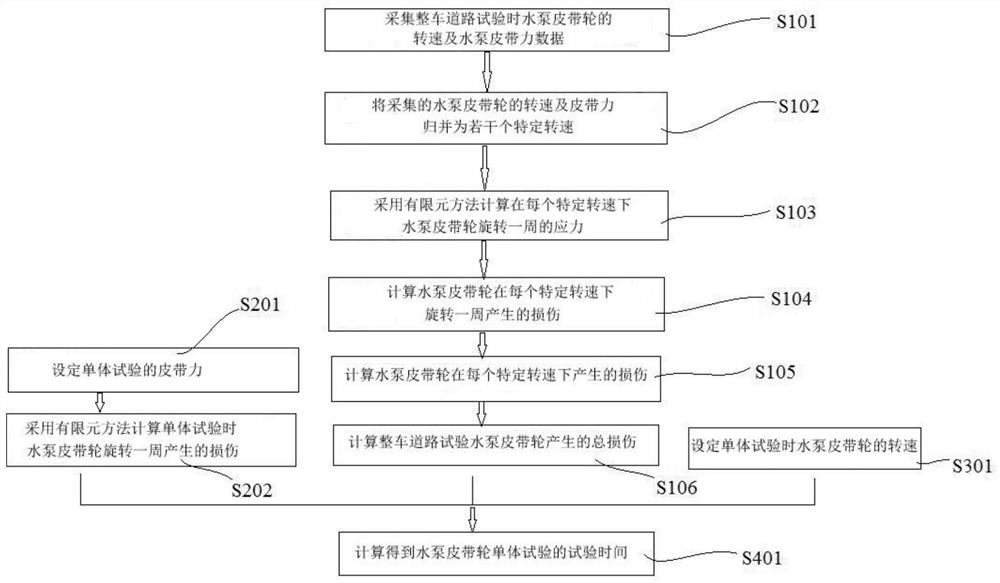

[0024] Such as figure 2 The automotive engine water pump pulley test design method shown in , which includes S101 to S106, S201 to S202, S301 and S401.

[0025] S101, collecting the rotational speed of the water pump pulley and the force data of the water pump belt during the vehicle road test;

[0026] In practice, it is difficult to directly measure the above two data, and it is usually obtained by converting other data. Specifically, the rotational speed of the water pump pulley can be obtained by multiplying the crankshaft rotational speed of the engine obtained through the test by the rotation ratio, as shown in image 3 As shown, the speed of the water pump pulley is equal to the speed of the engine crankshaft multiplied by the transmission ratio two. For the belt force of the water pump belt, it is first necessary to test the force of the idler in the front-end a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com