Detection structure for water purifier and control method of detection structure

A technology for detecting structures and water purifiers, used in instruments, measuring devices, scientific instruments, etc., can solve problems such as difficult alignment, water ingress and damage to connectors, and achieve the effect of stable power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

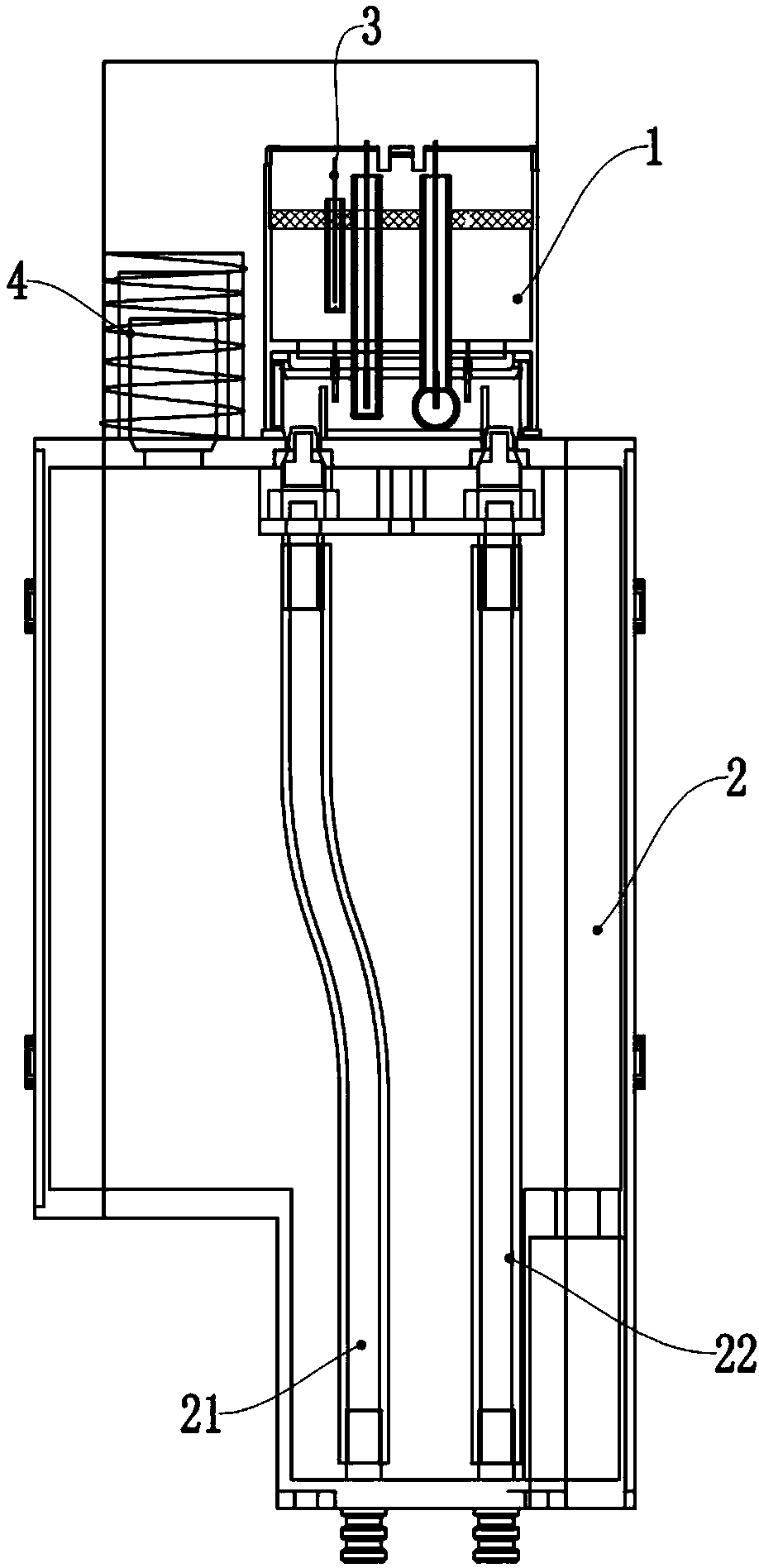

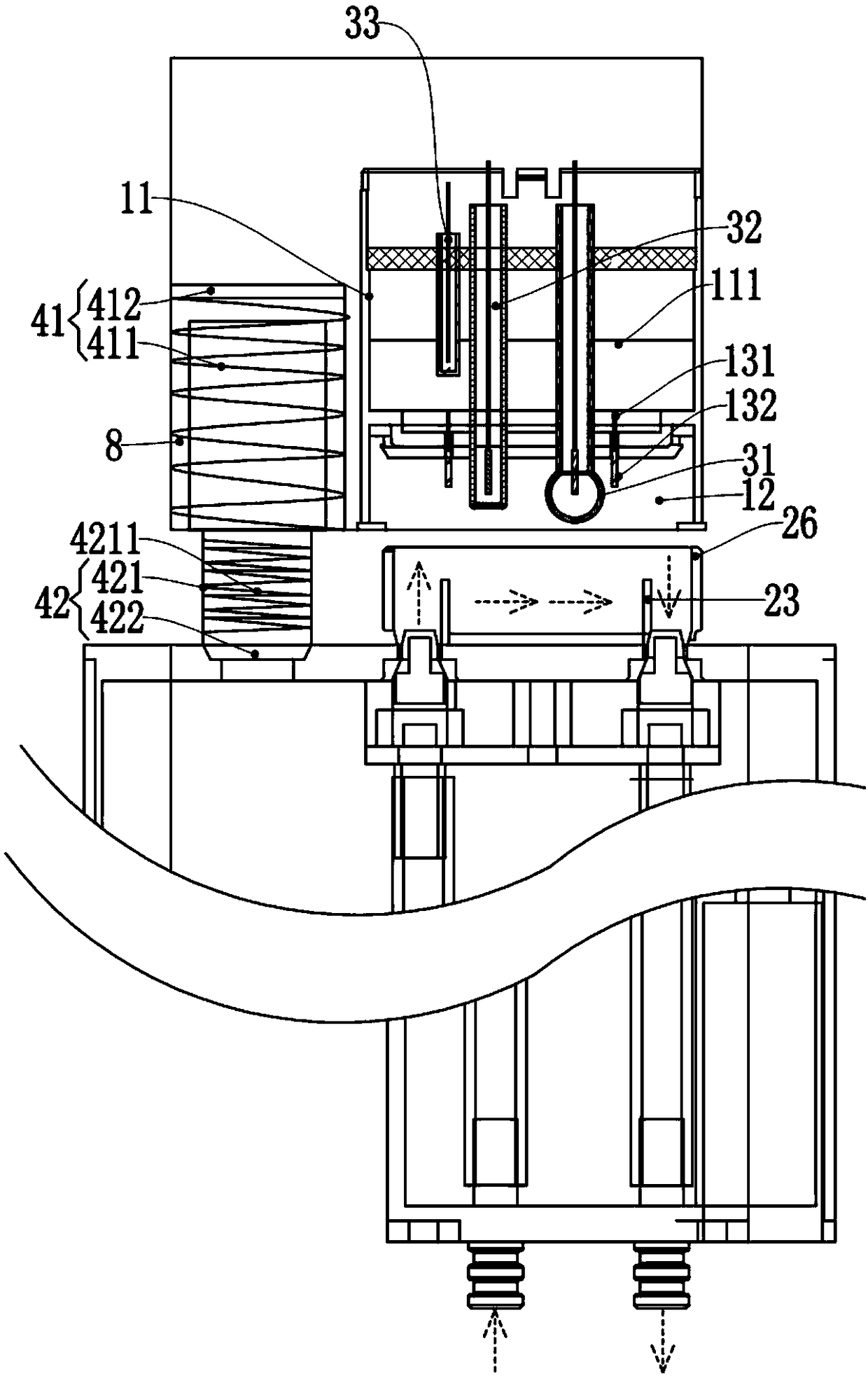

[0059] A detection structure for a water purifier, comprising: a detection shell cap 1, a housing 2, a power receiving device 4 and an application device 3;

[0060] The detection shell cap 1 is detachably connected to the housing 2; the application device 3 is arranged in the housing 2;

[0061] The power receiving device 4 includes: a detection module 41 and a host component 42;

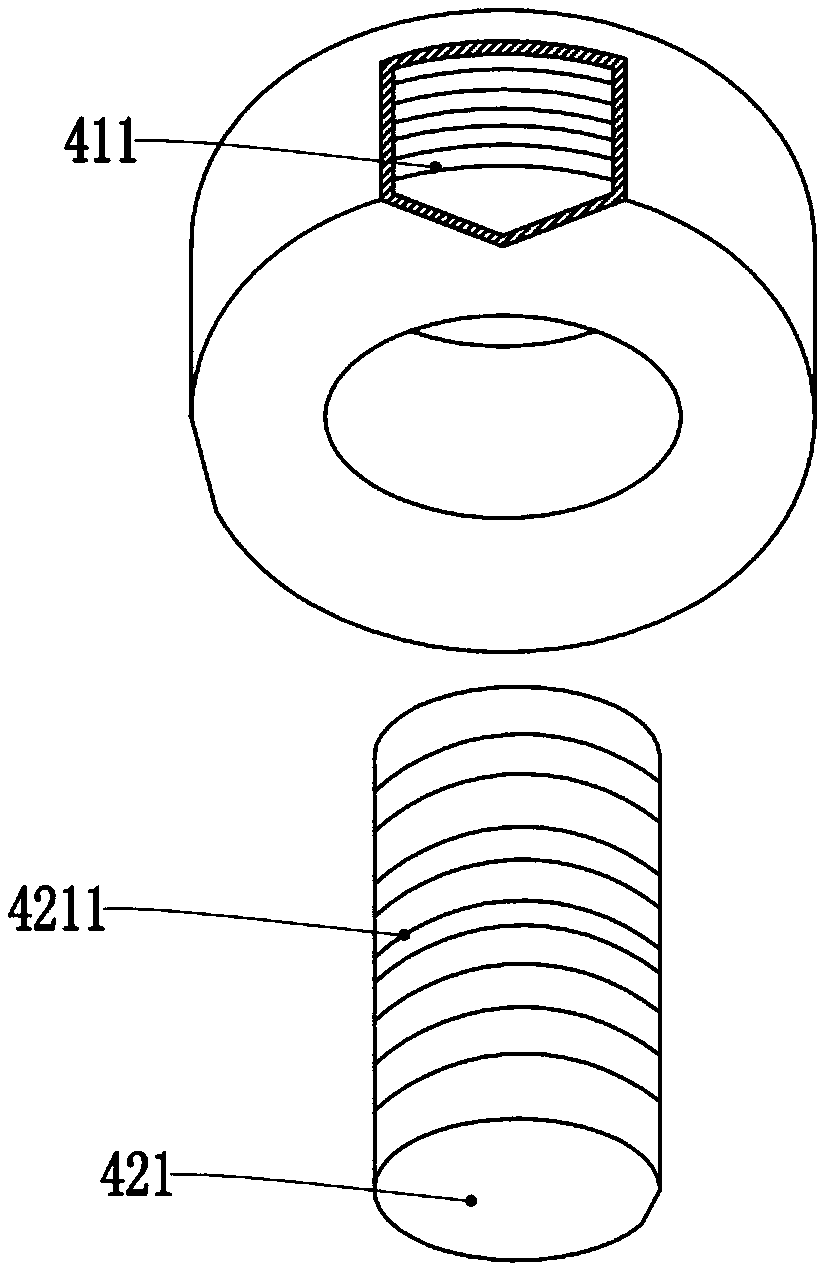

[0062]The detection module 41 includes: a receiving module 411 and an information receiving board 412; the receiving module 411 is connected to the information receiving board 412;

[0063] The host assembly 42 includes: a host transmitter module 421 and a host driver board 422; the host transmitter module 421 is connected to the host driver board 422; the host transmitter module 421 is provided with a transmitter coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com